Fluorescent molecular probe and use for inspecting transient metal and heavy metal ion

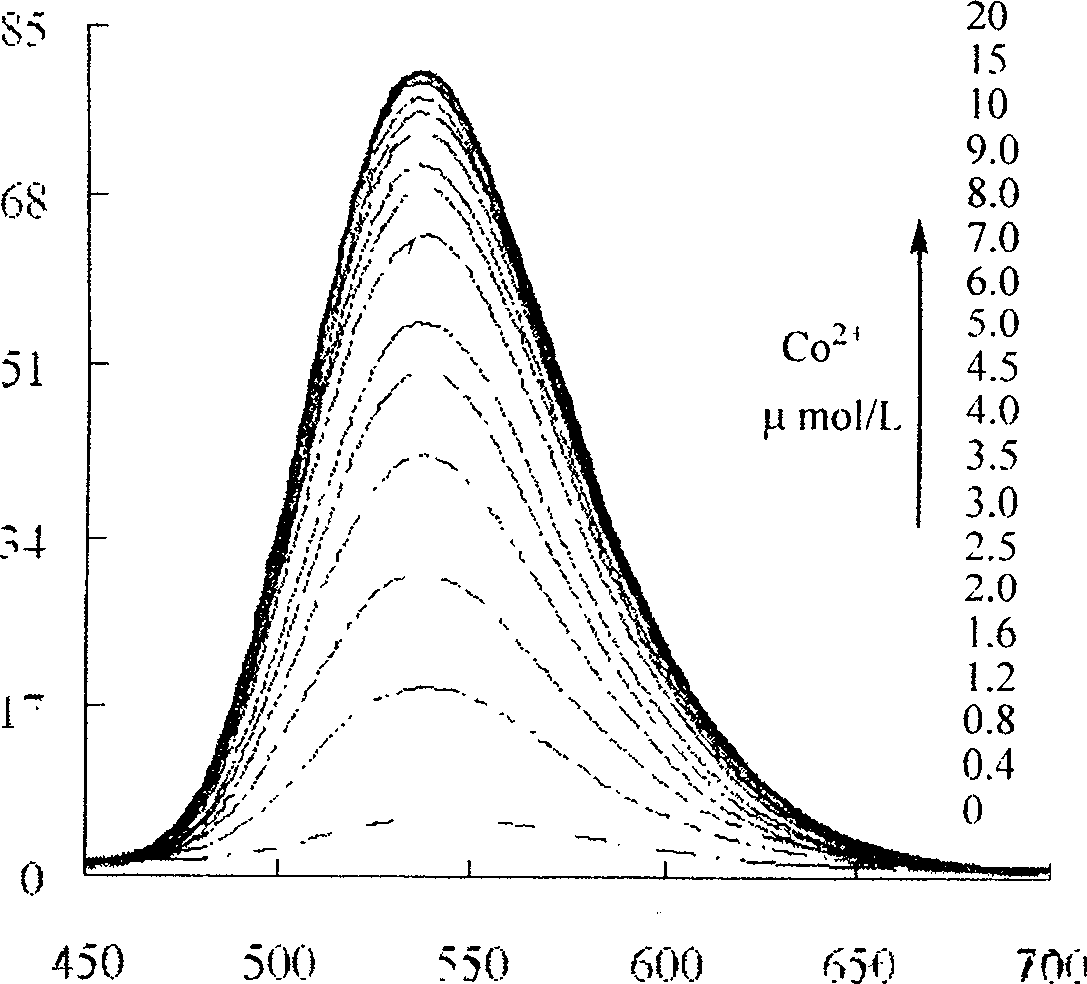

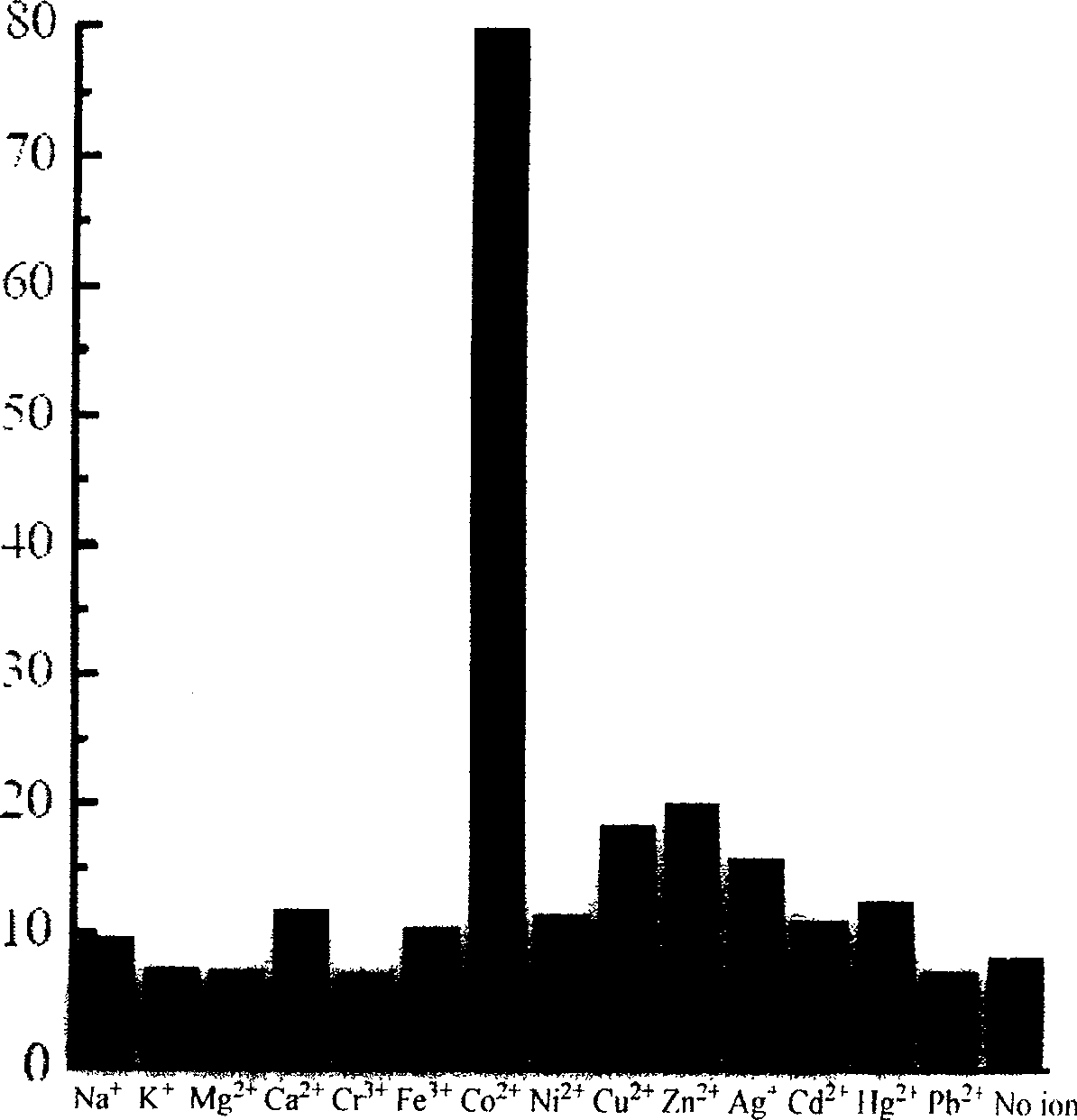

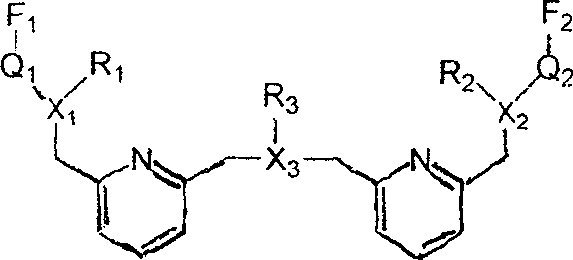

A technology of fluorescent molecular probe and molecular structure, which is applied in the field of application of the fluorescent molecular probe in the identification and detection of transition metal and heavy metal ions, and achieves the effects of good selective fluorescence enhanced recognition and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029]

[0030] N-butyl-4-(2-(2-hydroxyethylamino)ethylamino)-1,8-naphthalimide 180mg (0.385mmol), 2,6-dichloromethylpyridine 70mg (0.40mmol) Dissolve in 50ml of acetonitrile, reflux for about 8h. The solvent was evaporated. The intermediate (P-1-1) was separated by silica gel column chromatography as dark yellow viscous liquid, yield: 69% (130mg).

[0031] The above-mentioned intermediate P-1-1130mg (0.262mmol), monoethanolamine 8mg (0.13mmol) was added to 50ml of acetonitrile solvent, N 2 Protection, heated to reflux for about 7h, cooled to room temperature. After the reaction solution was spin-dried, it was separated by silica gel column chromatography to obtain a dark yellow viscous liquid (P-1). Yield: 55% (70mg). 1 H-NMR (400MHz, CDCl 3 )δ: 8.46(d, J=7.2Hz, 2H), 8.27(d, J=8.4Hz, 2H), 8.15(d, J=8.2Hz, 2H), 7.44(m, 4H), 6.95(m, 4H), 6.53(br, 2H), 4.16(t, J=7.6Hz, 4H), 3.6-3.8(m, 14H), 3.20(br, 4H), 2.98(br, 6H), 2.75(br, 4H ), 1.70(m, 4H), 1.44(m, 4H), 0.97(t, J=6...

Embodiment 2

[0033]

[0034] Add 401 mg (1.09 mmol) of N-hydroxyethoxyethyl-4-piperazinyl-1,8-naphthalimide and 229 mg (1.30 mmol) of 2,6-dichloromethylpyridine to 50 ml of acetonitrile solvent , N 2 Protection, heated to reflux for about 6h, cooled to room temperature. The reaction solution was spin-dried and separated by silica gel column chromatography to obtain a light yellow solid (P-2-1). Melting point: 119.3-120.1°C, yield: 53% (290 mg).

[0035] Add P-2-1203mg (0.398mmol) and monoethanolamine 11mg (0.18mmol) to 30ml of acetonitrile solvent, N 2 Protection, heated to reflux for about 6h, cooled to room temperature. After the reaction solution was spin-dried, it was separated by silica gel column chromatography to obtain a yellow solid (P-2). Melting point: 89.0-90.1°C, yield: 45% (80 mg).

[0036] 1 H-NMR (400MHz, CDCl 3 )δ: 8.57(d, J=7.2Hz, 2H), 8.50(d, J=8.4Hz, 2H), 8.40(d, J=8.4Hz, 2H), 7.66(m, 4H), 7.38(d, J=7.2Hz, 2H), 7.30(d, J=10.8Hz, 2H), 7.20(d, J=8.4Hz, 2H), 4.4...

Embodiment 3

[0038]

[0039] Add 380 mg (1.126 mmol) of N-butyl-4-piperazinyl-1,8-naphthalimide and 200 mg (1.136 mmol) of 2,6-dichloromethylpyridine into 50 ml of acetonitrile solvent, N 2 Protection, heated to reflux for about 7h, cooled to room temperature. After the reaction solution was spin-dried, it was separated by silica gel column chromatography to obtain the intermediate as a yellow-green solid (P-3-1). Melting point: 147.0-147.8°C, yield: 58% (290mg).

[0040] Take the above-mentioned intermediate P-3-1172mg (0.360mmol), monoethanolamine 10mg (0.164mmol) and add it to 30ml of acetonitrile solvent, N 2 Protection, heated to reflux for about 6h, cooled to room temperature. After the reaction solution was spin-dried, it was separated by silica gel column chromatography to obtain a golden yellow solid (P-3). Melting point: 85.8-86.9°C, yield: 60% (92 mg). 1 H-NMR (400MHz, CDCl 3 )δ: 8.57(d, J=7.2Hz, 2H), 8.50(d, J=8.0Hz, 2H), 8.40(d, J=8.4Hz, 2H), 7.68(t, J=8.0, 2H), 7.63(...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com