Fibre-optical raster sensing device for monitoring metal rust

A technology of optical fiber gratings and sensing devices, which is applied in measuring devices, color/spectral characteristic measurement, weather resistance/light resistance/corrosion resistance, etc. It can solve the problems of inapplicable early and normal operation period monitoring, insensitivity to initial corrosion, etc. problem, to achieve the effect of simple structure, low cost and large parameter range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

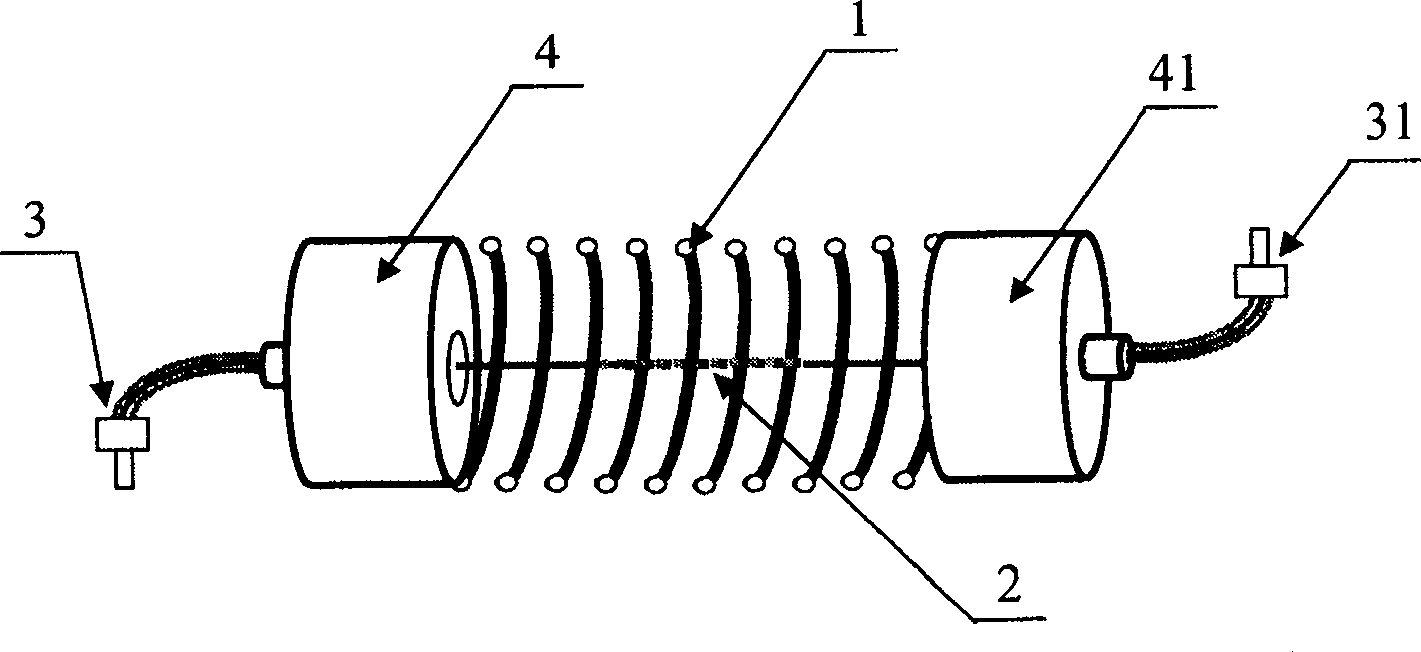

[0020] see first figure 1 , figure 1 It is a structural schematic diagram of Embodiment 1 of the present invention. 1 in the figure is a spring made of the metal material to be monitored, and the drawing in the figure is a cross-sectional view of the spring. 2 is a reflective fiber Bragg grating, 3 is the first fiber optic connector connected with the first fiber Bragg grating. The first support seat 4 and the second support seat 41 are support seats for fixing the spring and the first fiber grating 3 , and a small hole is drilled in the center of the two support seats along the axial direction so that the optical fiber can pass through. When installing the device of this structure, the spring 1 made of the metal to be monitored is fixed between the first support seat 4 and the second support seat 41, and the design of the first support seat 4 and the second support seat 41 allows the spring to move axially Tension and compression occur, but no bending occurs. The spring 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com