Buried cable carbon-screw protective tube produced by utilizing waste plastic-steel

A sheathing and thread technology is applied in the field of flame-retardant buried cable carbon thread sheathing, which can solve the problems of high sheathing price, affecting the ecological environment, waste of limited resources, etc., so as to improve the utilization rate of resources and improve the Economic benefits, the effect of lowering the ex-factory price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

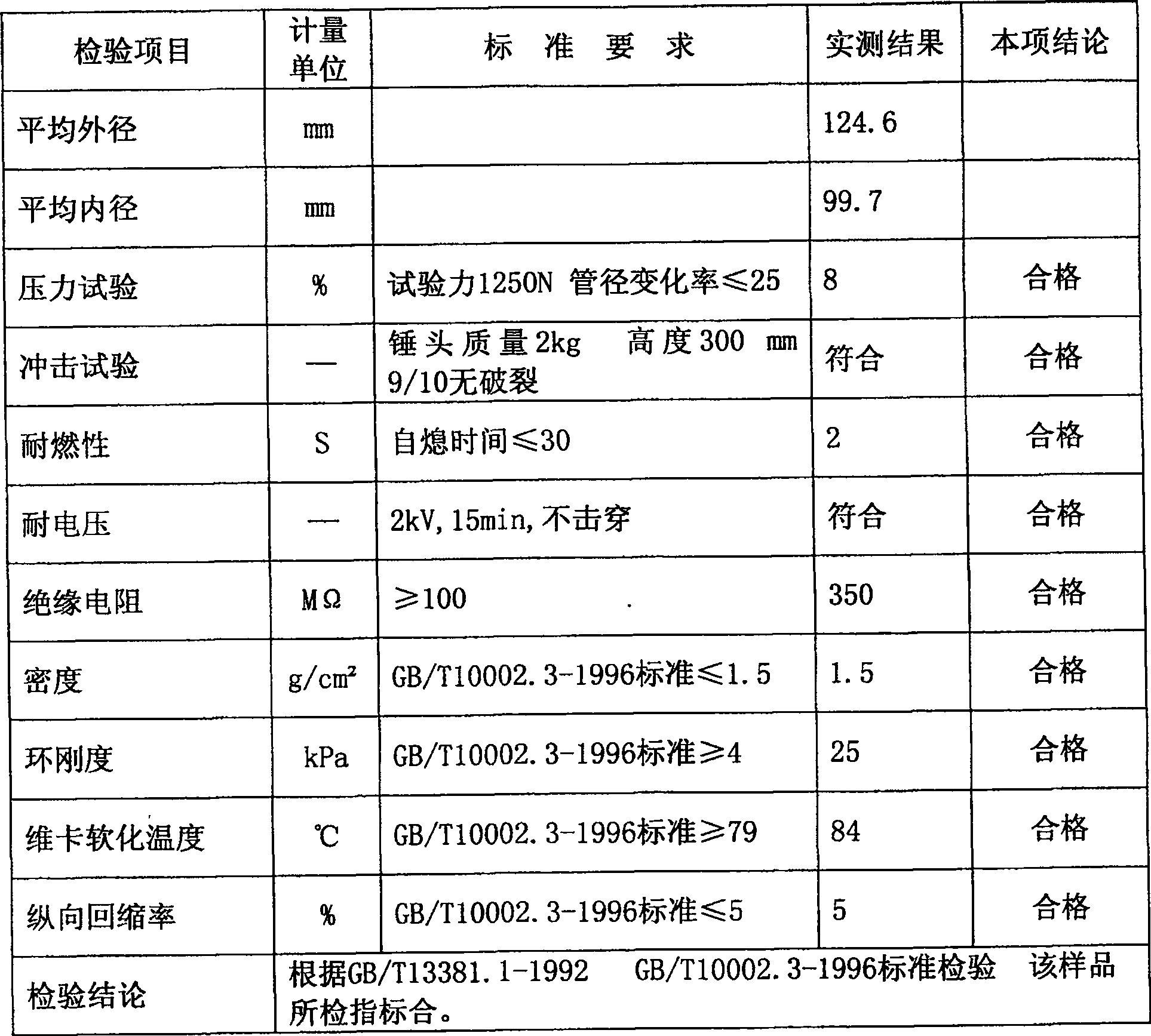

Examples

Embodiment 1

[0023] First select materials for the recovered waste plastic steel, remove the impurities in it, then use a pulverizer to crush the waste plastic steel after removal of impurities into particles of no more than 10mm, and then use a mill to grind it into a 50-mesh fine powder to obtain waste plastic steel powder ; Take raw material (kg) as follows:

[0024] Waste plastic steel powder 82kg, chlorinated polyethylene 6kg, FJ-3001.45kg, paraffin 0.33kg, stearic acid 0.22kg, carbon black 4.2kg, soft polyvinyl chloride 5.8kg.

[0025] Put the above raw materials into the mixing metal barrel and mix them evenly, then enter into the batching kneader and knead until the temperature reaches 100 degrees, take them out, enter into the twin-screw extruder, control the temperature of the barrel of the extruder at 149-180°C (that is, 160°C in the first zone ℃, 170 ℃ in the second zone, 180 ℃ in the third zone, 149 ℃ in the fourth zone, the twin-screw speed is controlled at 40 rpm, and then t...

Embodiment 2

[0027] First select materials for the waste plastic steel, remove impurities therein, then use a pulverizer to crush the waste plastic steel after removal of impurities into particles of no more than 10mm, and then use a pulverizer to finely grind it into a 60-mesh fine powder to obtain waste plastic steel powder; Weigh the raw materials (kg) as follows:

[0028] Waste plastic steel powder 86kg, chlorinated polyethylene 4.0kg, FJ-3001.4kg, paraffin wax 0.27kg, stearic acid 0.18kg, carbon black 4.65kg, polyethylene wax 1.2kg, dioctyl ester 2.3kg.

[0029] Put the above-mentioned raw materials into the mixing metal barrel and mix them evenly, then enter into the batching kneader and knead until the temperature reaches 100°C, take them out, enter into the twin-screw extruder, control the temperature of the barrel of the extruder to 150-178°C (1 zone 165°C , Zone 2 175°C, Zone 3 178°C, Zone 4 150°C), the twin-screw speed is controlled at 35 rpm, and then the die is shaped (the die...

Embodiment 3

[0031] First select materials for waste plastic steel, remove impurities therein, then use a pulverizer to crush the waste plastic steel after removal of impurities into particles of no more than 10mm, and then use a pulverizer to finely grind it into a 45-mesh fine powder to obtain waste plastic steel powder; Weigh the raw materials (kg) as follows:

[0032] Waste plastic steel powder 84kg, chlorinated polyethylene 5kg, FJ-3021.5kg, paraffin 0.3kg, stearic acid 0.2kg, carbon black 4kg, polyethylene wax 1kg, dioctyl ester 3kg, ACR (acrylic ester resin, commercially available ) 1kg.

[0033] Put the above raw materials into the mixing metal barrel and mix them evenly, then enter the batching kneader and knead until the temperature reaches 100°C, take them out, enter the twin-screw extruder, and control the temperature of the barrel of the extruder to 151-1770°C (that is, the first zone 162 ℃, 173℃ in the second zone, 177℃ in the third zone, 151℃ in the fourth zone), the twin-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com