Cleaning agent composition

A cleaning agent and composition technology, which is applied in the field of cleaning agent compositions, can solve the problems of strong odor, insufficiency, and insufficient dissolving and removability of aromatic compounds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] The present invention is further described in detail through examples below, but the present invention is not limited to these examples. In addition, the abbreviations of the organic solvent used in each Example and the comparative example represent the following compounds, respectively.

[0032] (1) Alkylene glycol alkyl ether

[0033] monoalkyl ether

[0034] DPGME: Dipropylene Glycol Monomethyl Ether

[0035] TPGME: Tripropylene Glycol Monomethyl Ether

[0036] DPGPE: Dipropylene Glycol Monopropyl Ether

[0037] PGME: Propylene Glycol Monomethyl Ether.

[0038] dialkyl ether

[0039] DPGDME: Dipropylene Glycol Dimethyl Ether

[0040] DEGMEE: Diethylene glycol methyl ethyl ether

[0041] TEGDME: Triethylene glycol dimethyl ether

[0042] (2) Hydrocarbon solvents

[0043] Naphthenic

[0044] TPS-3200: Tokuyama Co., Ltd. naphthenic hydrocarbon cleaning agent TPS-3200

[0045] C n h 2n n=11~13 ignition point 74℃

[0046] Isoalkane

[0047] TPS-1150: To...

reference example 1

[0053] Kokonoe grinding bitumen grade K grade No. 8 (manufactured by Konoe Electric Co., Ltd.) was shaped into a button shape with a diameter of 6 mm, and a fixed sample was prepared. The weight of the fixed bitumen was measured and found to be 56.2 mg. Next, this sample was immersed in 20 ml of cleaning agent (Naphthene-based cleaning agent TPS-3200 manufactured by Tokuyama Corporation) maintained at 25° C. for 20 minutes. Afterwards, the sample was taken out, dried, and the weight of the remaining pitch attached to the glass plate was measured, and the result was 17.1 mg. The weight of the removed pitch was 39.1 mg after subtracting the residual weight difference from the initial weight.

[0054] In addition, visual observation of the cleaning solution during and after the sample immersion showed no peeling of pitch, and it was a uniform solution. It can be seen that the asphalt is all removed by dissolution.

[0055] Refer to Comparative Examples 1 and 2

[0056] In addit...

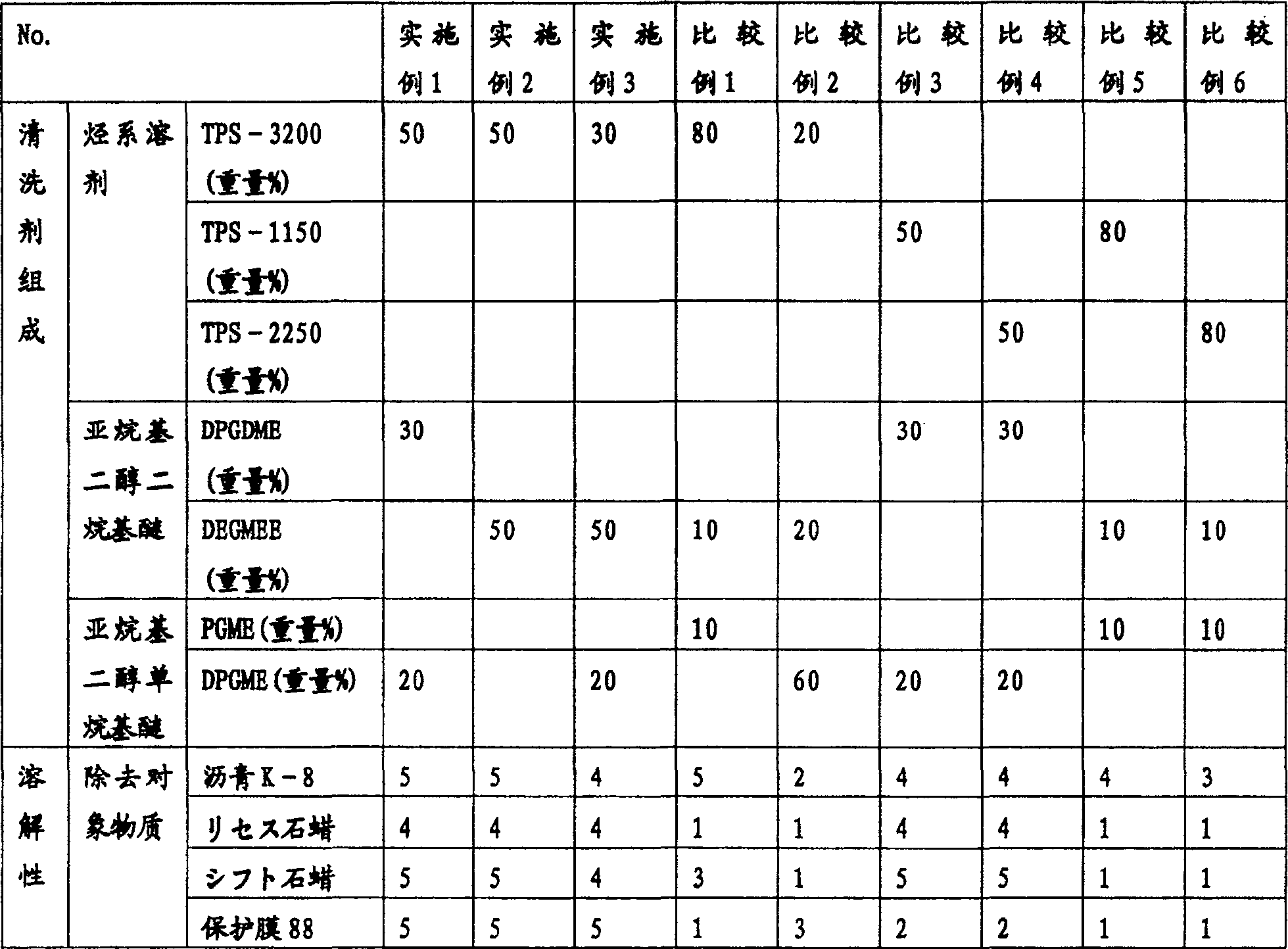

Embodiment 1~3 and comparative example 1~6

[0061] For cleaning agents using the compositions shown in Table 2, various removal target substances [cleaning target substances: Kokonoe asphalt grade K grade No. 8 (manufactured by Konoe Electric Co., Ltd.) (hereinafter referred to as bitumen K-8), Lyses paraffin (grade No. 5 manufactured by Kokonoe Electric Co., Ltd.) (hereinafter referred to as Lyses paraffin), Shift paraffin (5408R Nichika Seiko Co., Ltd., hereinafter referred to as Shift paraffin), protective film LG#88 ブラツク (Kanae Paint Co., Ltd.) ( The solubility of the following protective film 88)] was evaluated. The evaluation was performed by adding a small amount of the substance to be removed to various cleaning agents maintained at 25° C., and visually observing the solubility after leaving to stand for 5 minutes. In addition, when the substance to be removed was the protective film 88, a protective film that was applied to the lens for evaluation and then dried for one day was used.

[0062] The evaluation re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com