Modified method for lithium ion cell negative electrode material

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, electrode manufacturing, secondary batteries, etc., can solve problems such as inability to adapt to high-current power batteries, materials that cannot be obtained at the same time, cycle and capacity defects, etc., to achieve suppression Volume expansion and pulverization effects, good battery kinetics, and large aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

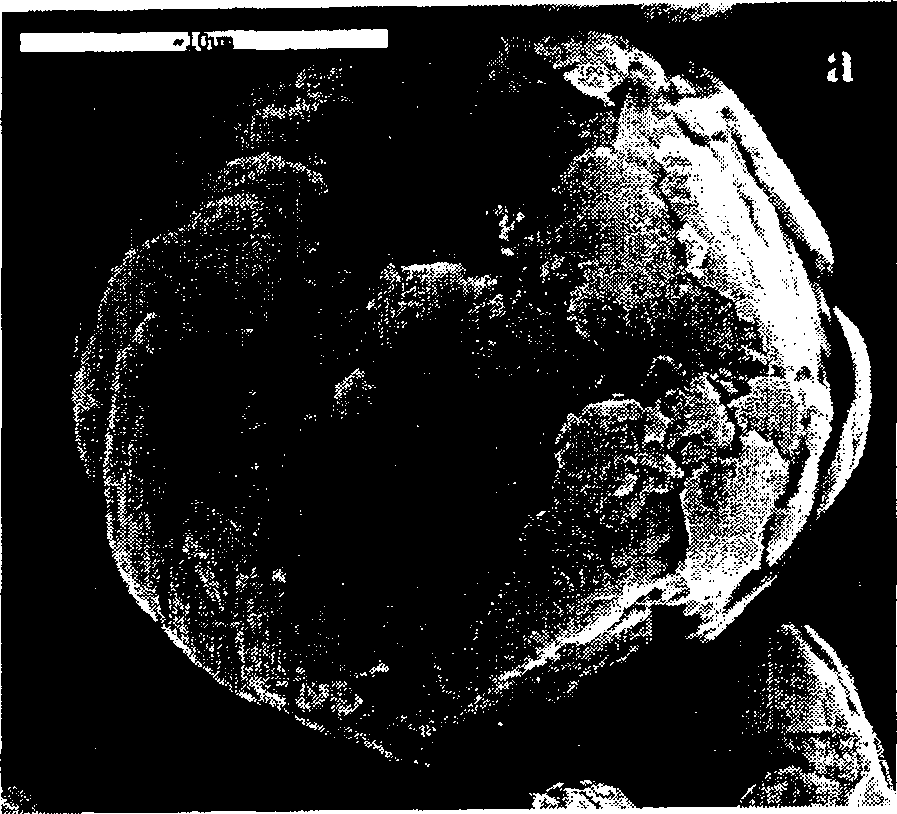

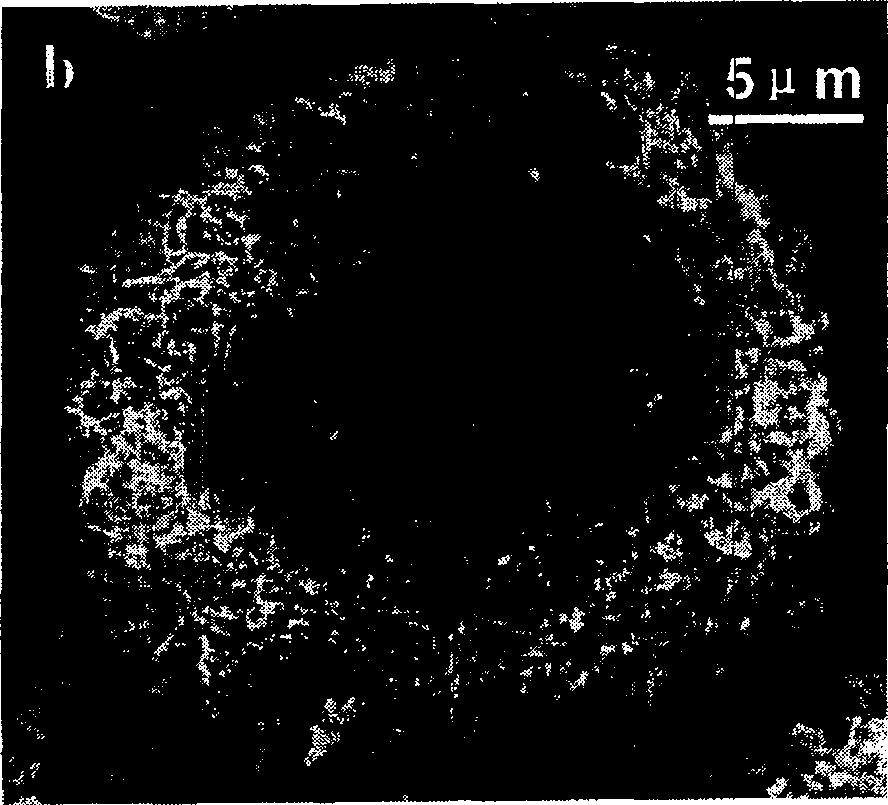

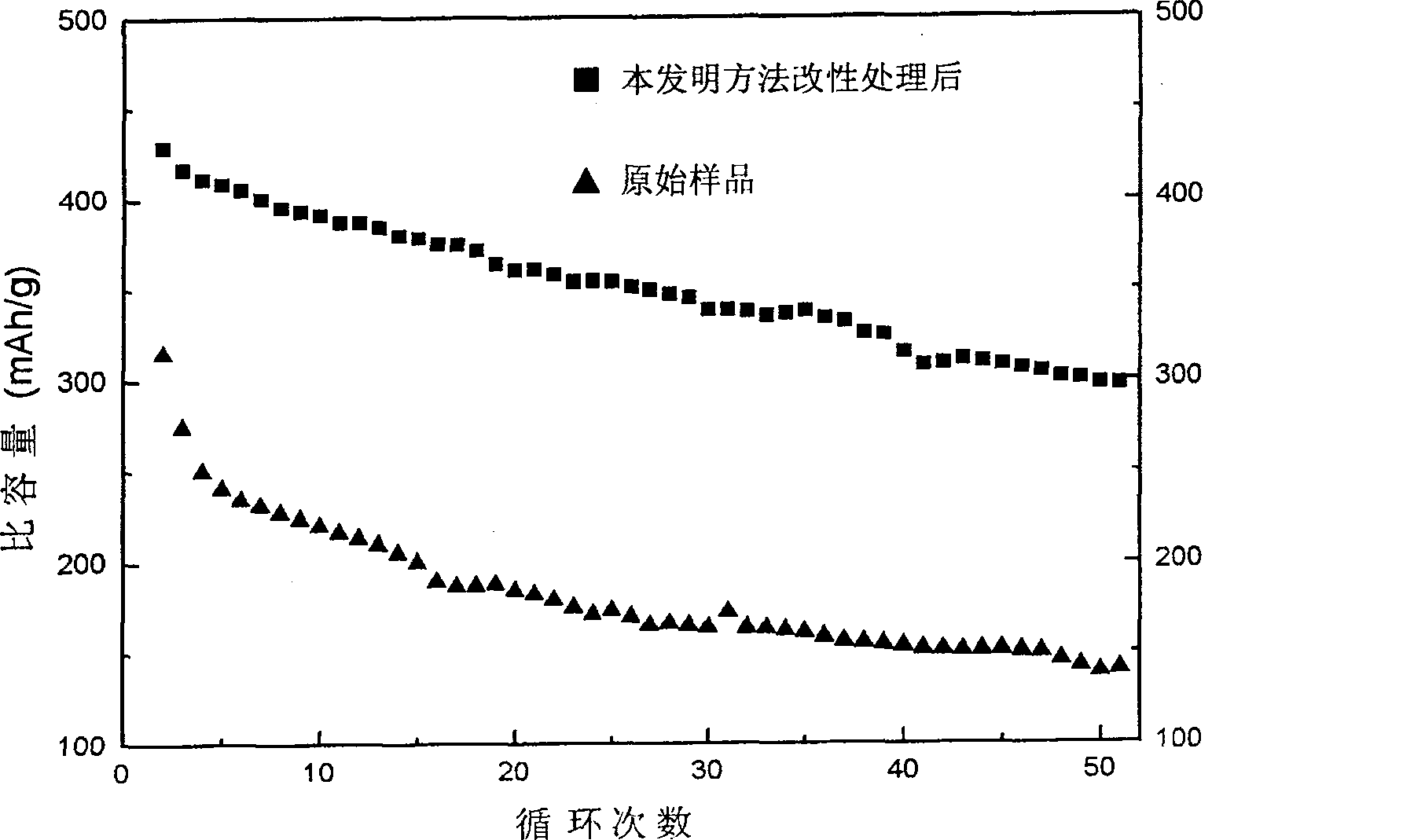

[0025] Use natural graphite balls (quality 2g) with an average diameter of 20 μm ( Figure 1a ), add Fe powder as catalyst (quality 0.046g), mix evenly, use C 2 h 4 Mix the carbon source and Ar at a volume ratio of 1:1, pass it into a reaction furnace at a temperature of 1000°C, and after 100 minutes of reaction, a modified composite with in-situ growth of nano-carbon fibers / carbon tubes on the surface is obtained. Negative material ( Figure 1b ). It is used as the negative electrode material of lithium ion battery. The detection results of the conventional lithium-ion battery negative electrode evaluation method show that under the same number of cycles, the capacity and cycle performance have been greatly improved ( figure 2 ).

Embodiment 2

[0029] Choose natural graphite balls (mass 2g) with an average diameter of 20 μm, add Fe(NO 3 ) 3 As a catalyst (mass 0.198g), natural graphite balls can be added to Fe(NO 3 ) 3 After mixing evenly in the solution, dry it with CH 4 as carbon source and N 2 Mix according to the volume ratio of 2:1, pass it into a reaction furnace at 700°C, and after 60 minutes of reaction, a modified composite negative electrode material with in-situ growth of nano-carbon fibers / carbon tubes on the surface is obtained. It is used as the negative electrode material of lithium ion battery. The detection results of the conventional lithium-ion battery negative electrode evaluation method show that the capacity and cycle performance have been greatly improved under the same number of cycles.

Embodiment 3

[0031] Choose natural graphite balls (mass 2g) with an average diameter of 20 μm, add Fe(NO 3 ) 3 As a catalyst (mass 0.084g), natural graphite balls can be added to Fe(NO 3 ) 3 After mixing evenly in the solution, dry it with CH 4 as carbon source and N 2 Mix at a volume ratio of 9:1, pass into a reaction furnace at a temperature of 700°C, and react for 240 minutes to obtain a modified composite negative electrode material with in-situ growth of nano-carbon fibers / carbon tubes on the surface. It is used as the negative electrode material of lithium ion battery. The detection results of the conventional lithium-ion battery negative electrode evaluation method show that the capacity and cycle performance have been greatly improved under the same number of cycles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com