Drifting outdoor barrel with carbon fiber composite and manufacturing method therefore

A technology of composite materials and manufacturing methods, which is applied in the drift chamber of BESIII detectors, can solve the problems of inability to produce weight of carbon fiber composite materials, and achieve the effect of light weight, large window and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

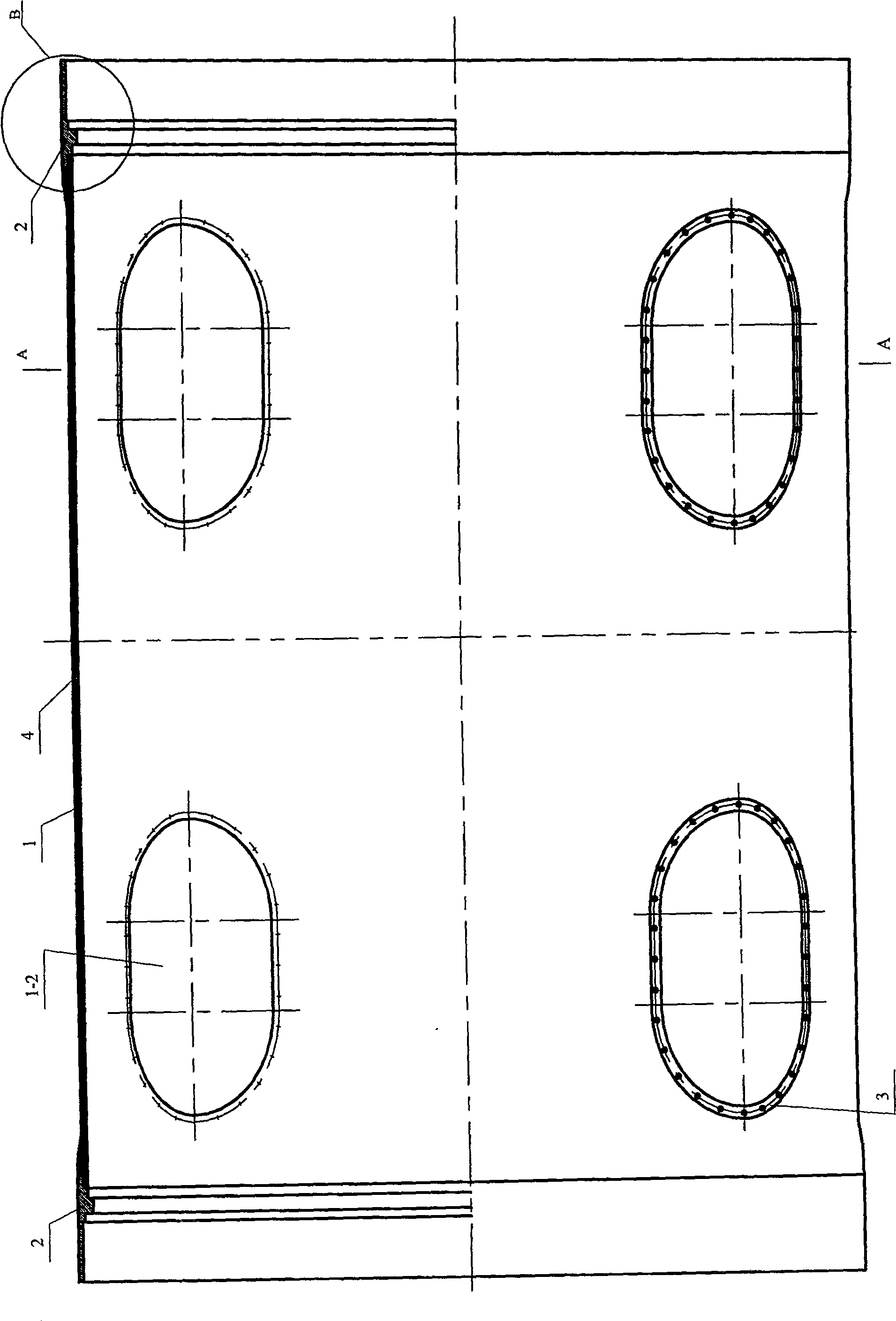

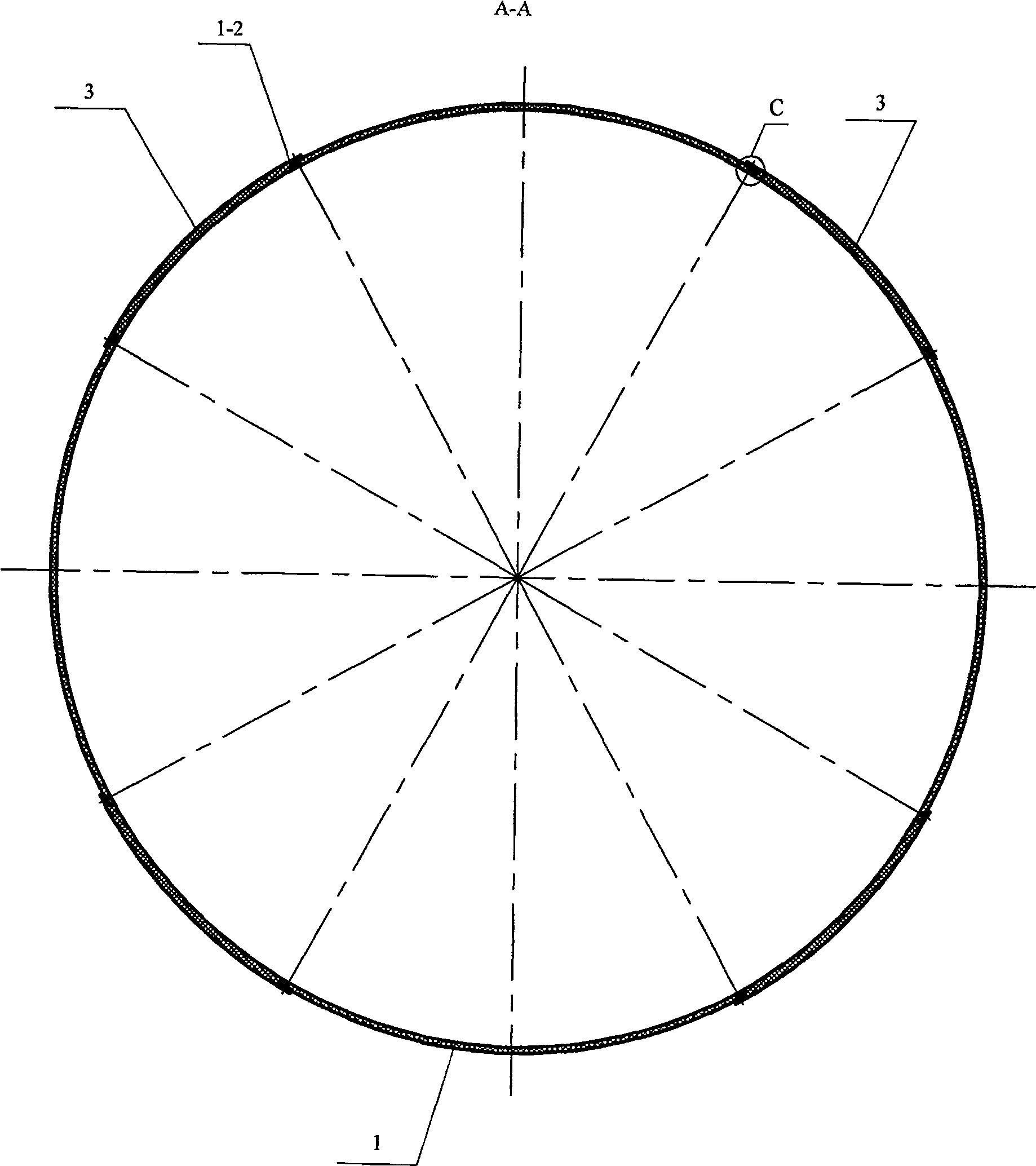

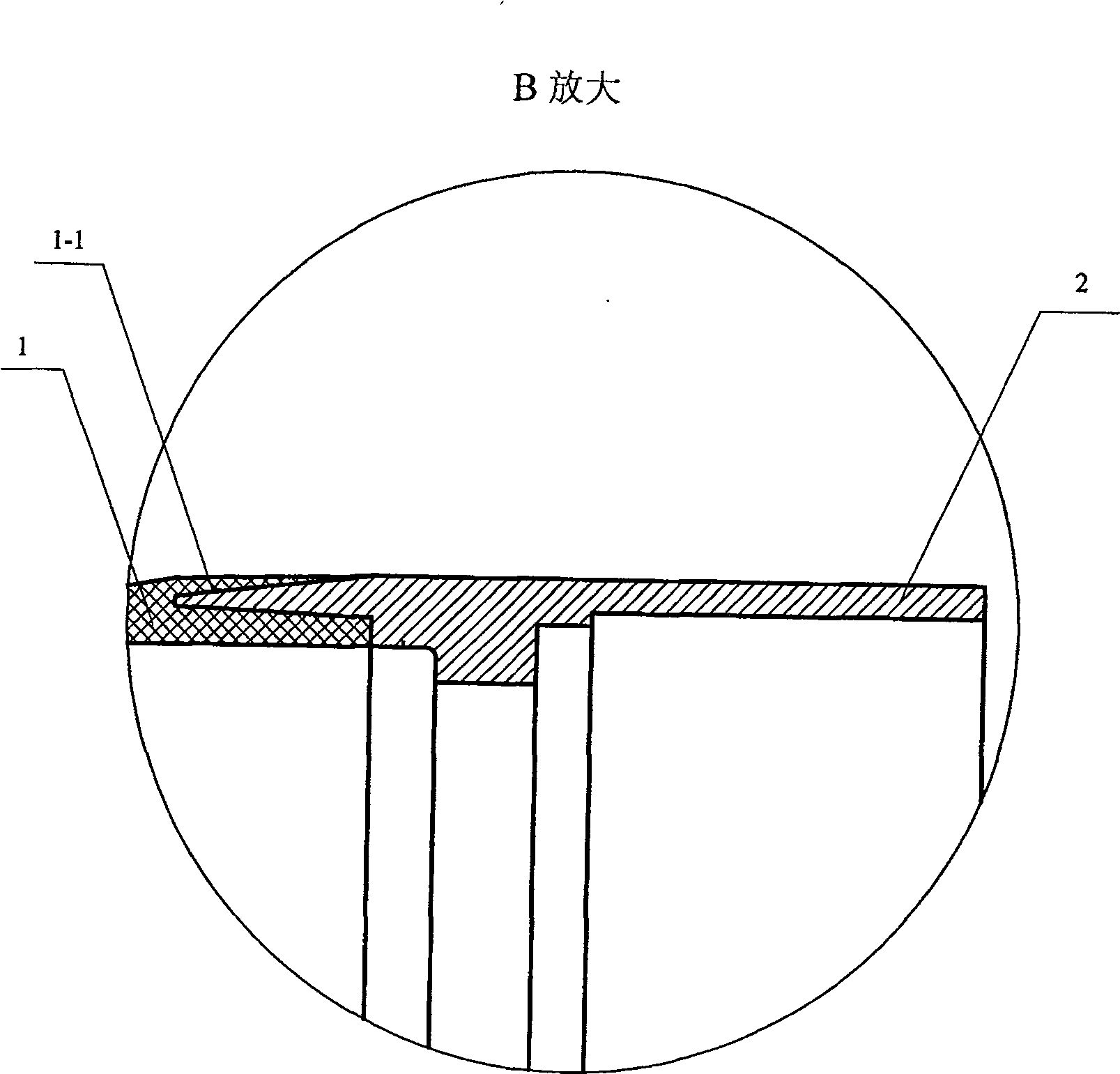

[0011] Specific implementation mode one: as figure 1 , figure 2 and image 3 As shown, the drifting outdoor cylinder of carbon fiber composite material in this embodiment is composed of a carbon fiber composite material cylinder body 1, an aluminum alloy seam ring 2, and a carbon fiber composite material window cover plate 3, and the cylinder body 1 is provided with eight windows. 1-2, the carbon fiber composite material window cover plate 3 is respectively covered on the eight windows 1-2 and connected with the windows 1-2, and the aluminum alloy stop ring 2 is bonded to the two sides of the carbon fiber composite material cylinder body 1 respectively. end 1-1.

[0012] The drifting outdoor cylinder in this embodiment has a length of 2582mm, an outer diameter of φ1620mm, and a wall thickness of 11.5mm. There are 8 windows on the cylinder body to meet the needs of wire drawing operations. After the wire drawing is completed, it is closed with a carbon fiber composite window...

specific Embodiment approach 2

[0013] Specific implementation mode two: as Figure 4 As shown, the periphery of the window 1-2 described in this embodiment is provided with a window cover plate installation and positioning platform 1-3, and the periphery of the carbon fiber composite material window cover plate 3 is correspondingly provided with a window cover plate installation platform 3-1 , A gasket 5 is provided between the window cover installation positioning platform 1-3 and the window cover installation platform 3-1. With such a structure, the window cover plate 3 is easy to install and easy to locate. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Embodiment 3: The carbon fiber composite material cylinder body 1 described in this embodiment has a wall thickness of 11-12 mm. This wall thickness is suitable for use in the drift chamber of the detector. Other compositions and connections are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com