Power material of proximity fuse used in explosive and preparation method therefor

A technology for explosives and fuzes, applied in the field of near-explosive fuze power supply materials and their preparation, can solve the problems of insufficient performance of fuze power supply materials, and achieve the effects of excellent chemical properties and electrical properties, guaranteed unchanged, and guaranteed performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

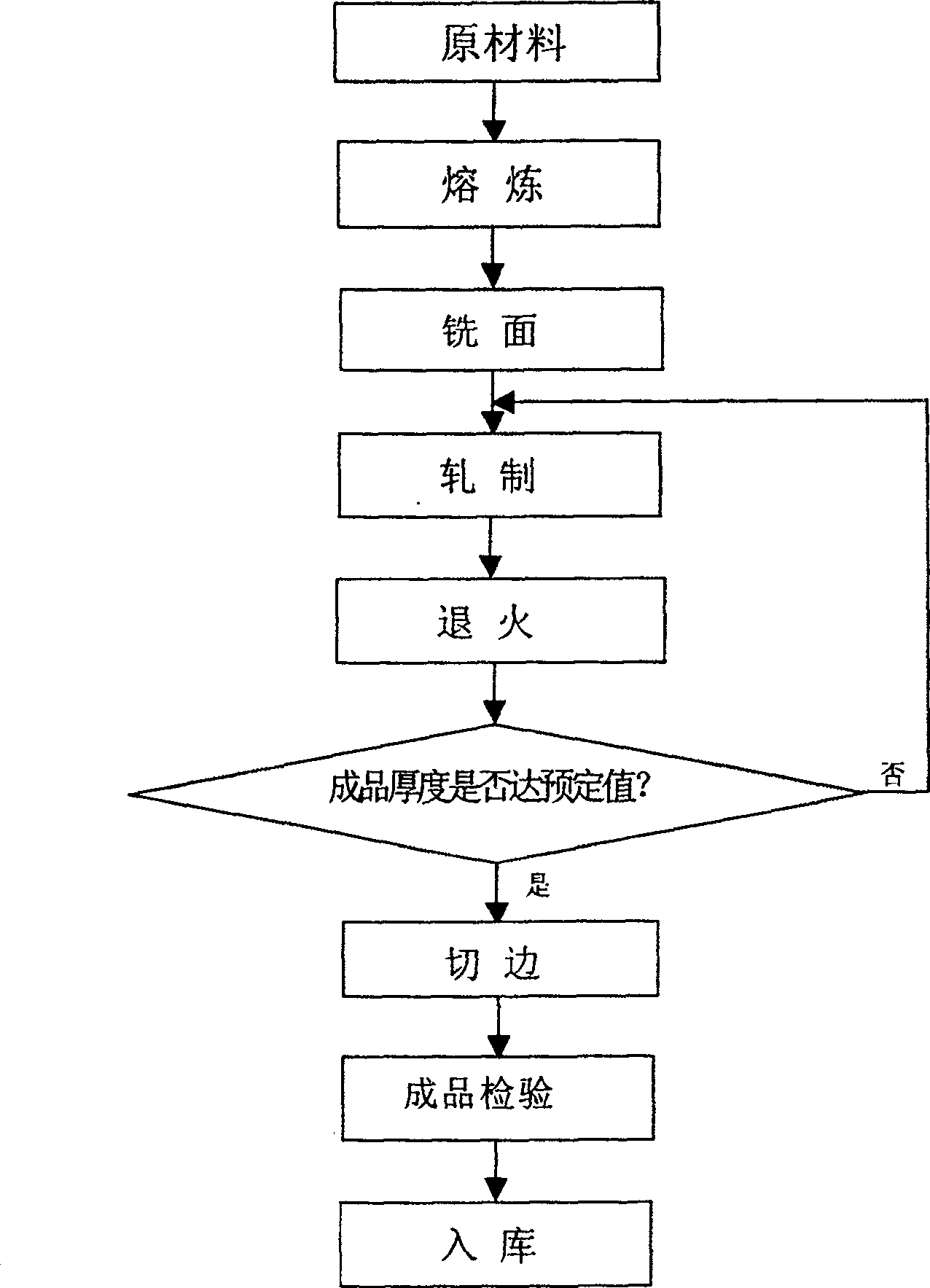

[0027] The power source material of the proximity fuze used for explosives of the present invention is a metal material calcium strip foil made of sponge calcium raw material through smelting, surface milling, repeated rolling and annealing. Such as figure 1 Shown: Its specific processing process is: raw material→smelting→face milling→rolling→annealing→rolling→annealing→rolling→annealing→rolling→edge trimming→finished product inspection.

[0028] Below in conjunction with specific embodiment, preparation method of the present invention is illustrated:

[0029] 1. Melting:

[0030] Raw material: Sponge calcium 99.9% Loading capacity: 1.8kg per furnace

[0031] Accessories: Ar gas; welding rod; packing cloth

[0032] Equipment: furnace body and stainless steel crucible, thyristor voltage regulator; copper mold, mechanical pump for vacuum system, carbon silicon rod furnace

[0033] operate:

[0034] Clean the valves of the vacuum system, clean the furnace body and crucible a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com