Preparing process of gas phase corrosion inhibitor

A gas-phase corrosion inhibitor and solution technology, which is applied in the field of preparation of gas-phase corrosion inhibitors, can solve the problems of damaging the release rate of gas-phase corrosion inhibitors and the deterioration of the anti-corrosion effect of gas-phase corrosion inhibitors. Application performance, improvement of gas phase corrosion inhibition ability, fine particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

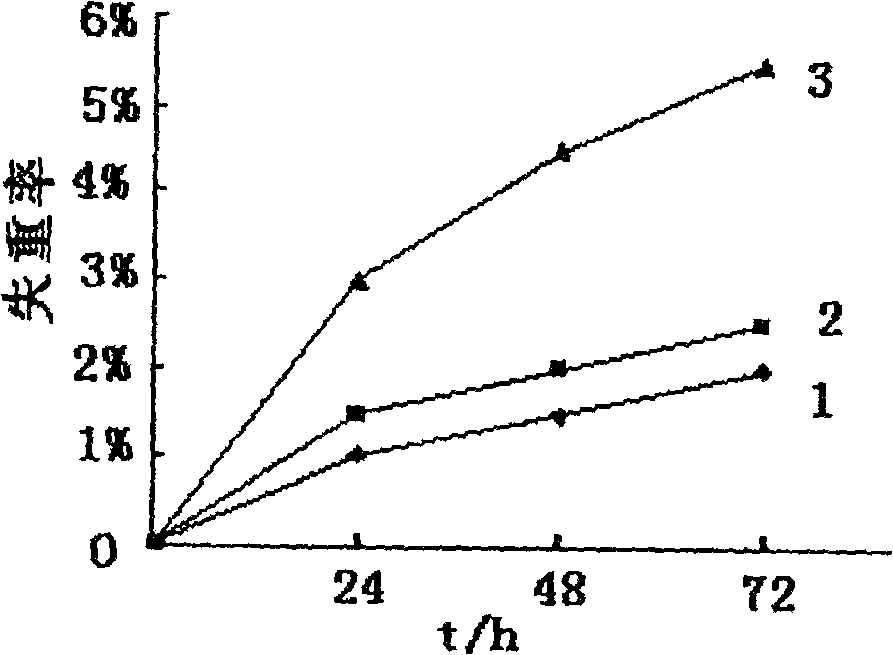

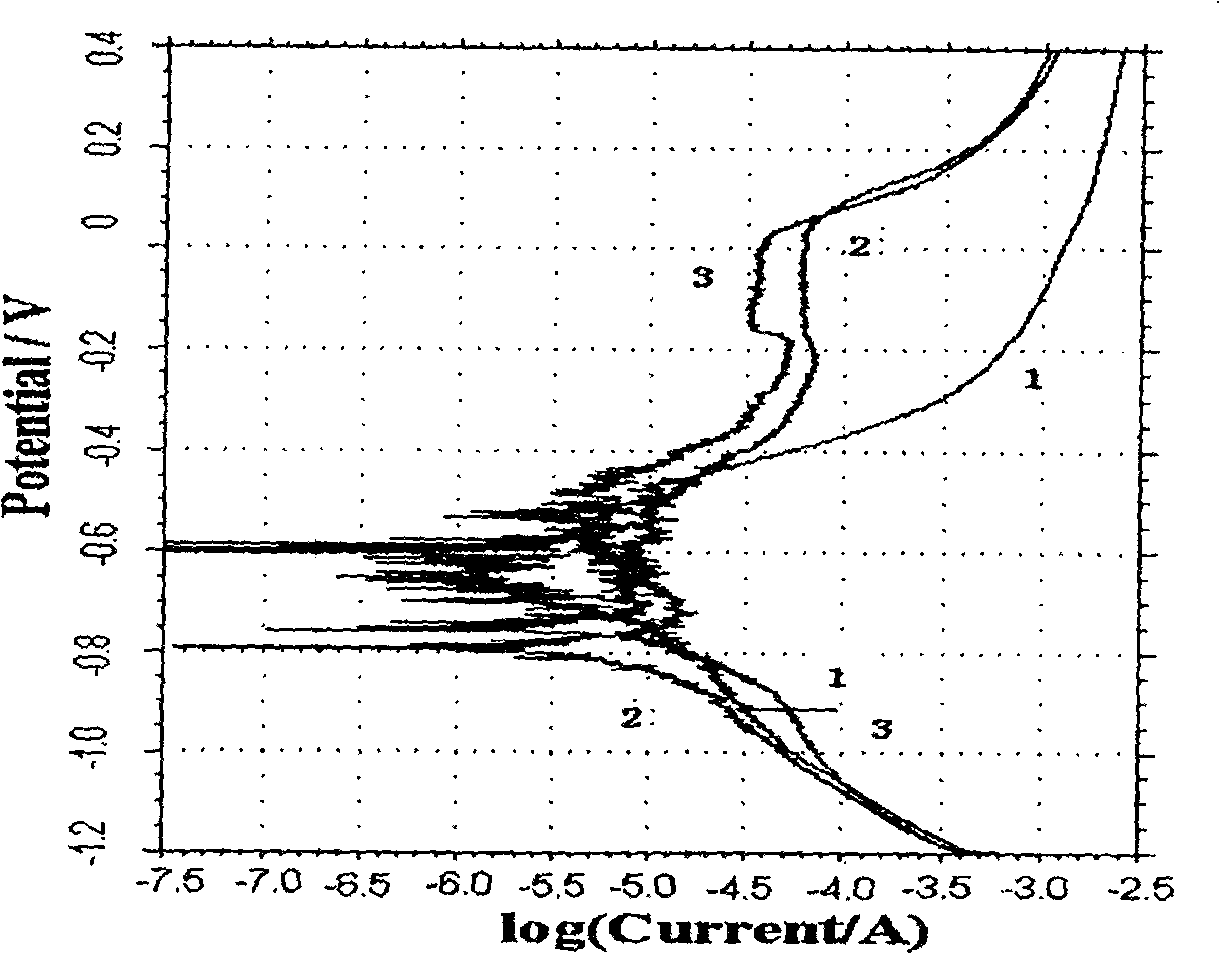

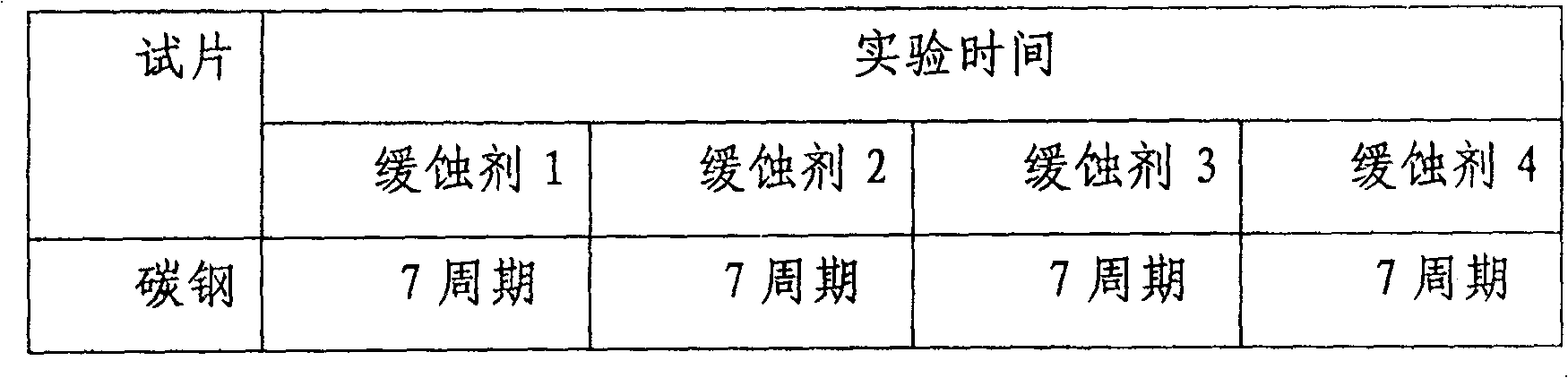

Embodiment 1

[0015] Weigh an appropriate amount of montmorillonite, disperse it in deionized water, make a slurry, activate the montmorillonite, stir for 24 hours, take the suspension of the solution, add a certain amount of morpholine to it, heat up to 80°C, and keep the temperature for 4-5 hour, at this moment, the solution evaporates and precipitates out a solid; add a certain amount of formaldehyde, stand for 4 hours, no obvious phenomenon; add a certain amount of dicyclohexylamine, stand for 3 hours, the solution is layered; the benzoic acid and acetone Add the mixed solution and let it stand for 8 hours to form a white slurry (note: during this process, continuous stirring is required), disperse the slurry in deionized water, and filter with suction to obtain a white powder, which is blown dry at 80°C , to obtain 52g of gas phase corrosion inhibitor 1.

Embodiment 2

[0017] 20 g of montmorillonite was formulated into a solution (5% by mass fraction), allowed to stand for a period of time, and the upper suspension was taken for later use. Add 30% cetyltrimethylammonium bromide solution (concentration is 105mmol / 100g soil) when 80 ℃, stir with suction after 1 hour, rinse 3-4 times with deionized water to minimize Br - , placed in an oven and dried at 120°C for 4 hours, then ground into a 500-mesh powder to obtain organic montmorillonite. Take 1.0g of modified montmorillonite and add 20ml of morpholine, stir at 50°C for 1 hour, slowly add 19.2ml of formaldehyde solution dropwise while stirring, observe the phenomenon after stirring for 2 hours, add 46ml of dicyclohexylamine dropwise, observe Phenomenon, after stirring for 3 hours, add benzoic acid solution (28g benzoic acid is dissolved in 40ml deionized water), observe the phenomenon, continue to stir for 4 hours, carry out suction filtration, put into oven drying, obtain 75g gas phase corro...

Embodiment 3

[0019] Weigh an appropriate amount of montmorillonite, disperse it in the ethanol solution, make a slurry, activate the montmorillonite, stir for 24 hours, take the suspension of the solution, add 5g of monoethanolamine to the above solution, mix and stir, dissolve 12g of benzoic acid In the ethanol solution, the two solutions were mixed with each other under constant stirring to produce a white precipitate, which was filtered by suction to obtain 15 g of gas phase corrosion inhibitor 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com