Equipment for collecting and processing acidity mist

A treatment device, acid mist technology, applied in the direction of removing smoke and dust, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of adverse environmental impact, unfavorable waste discharge concentration, large water consumption, etc., to achieve full use of water resources, excellent The effect of transmission power performance and high water utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

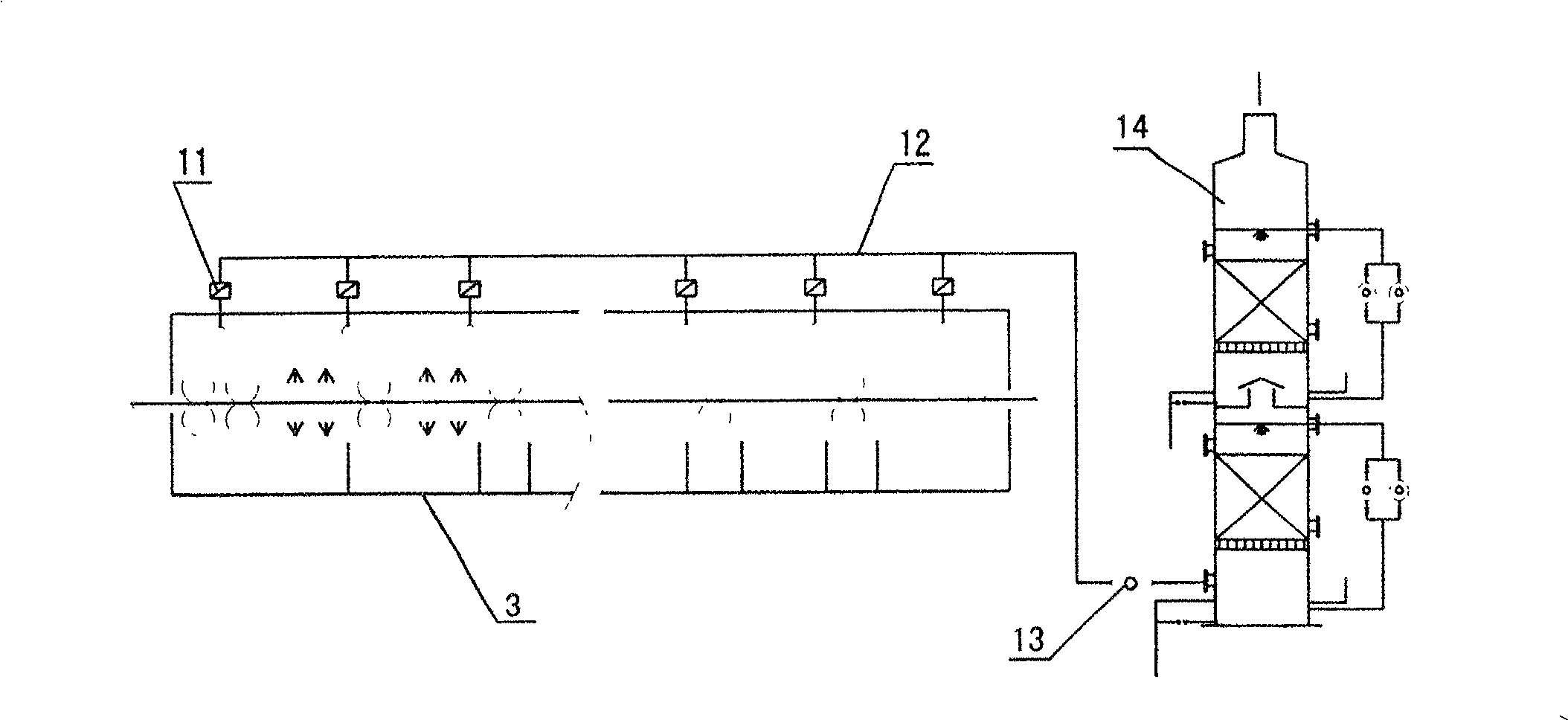

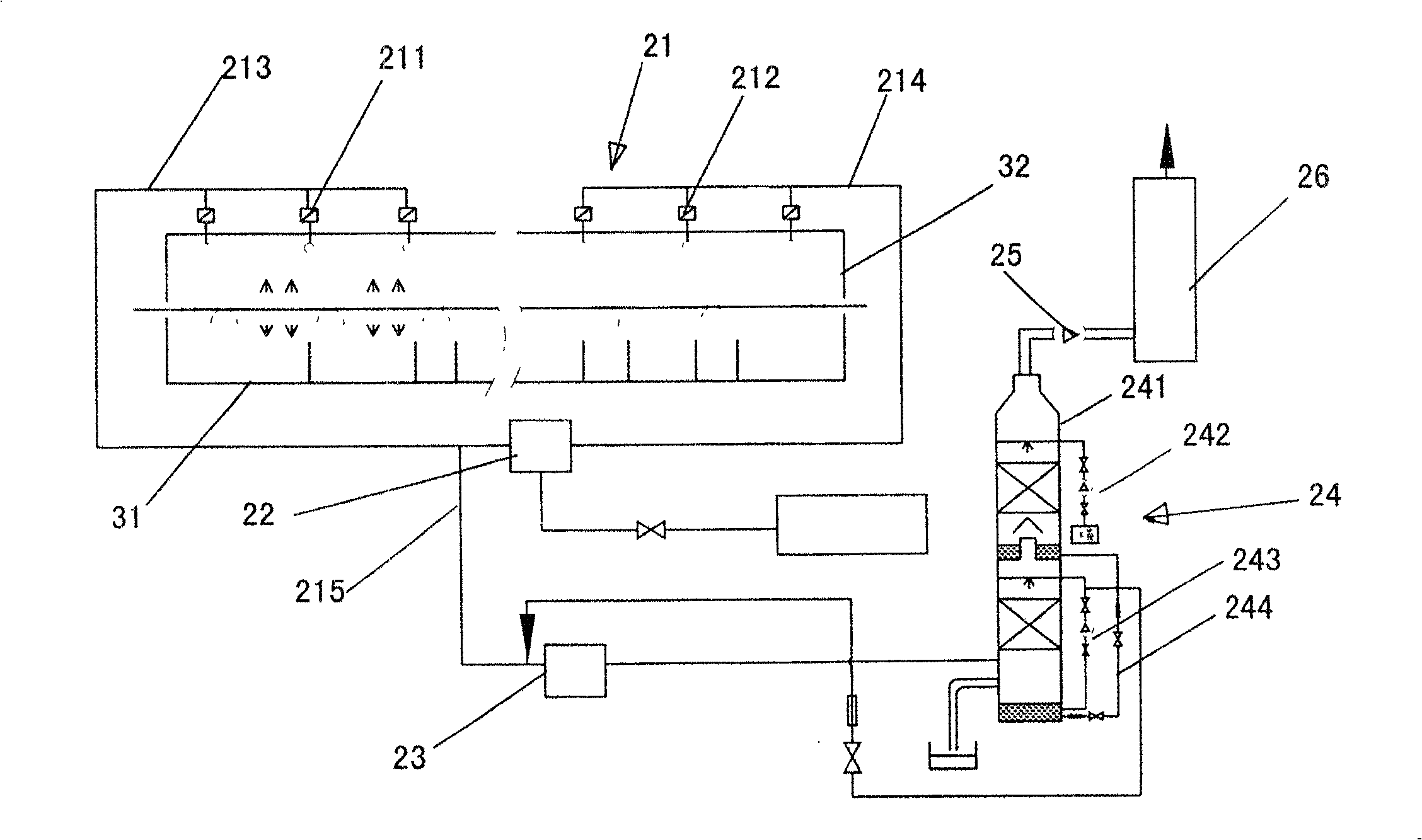

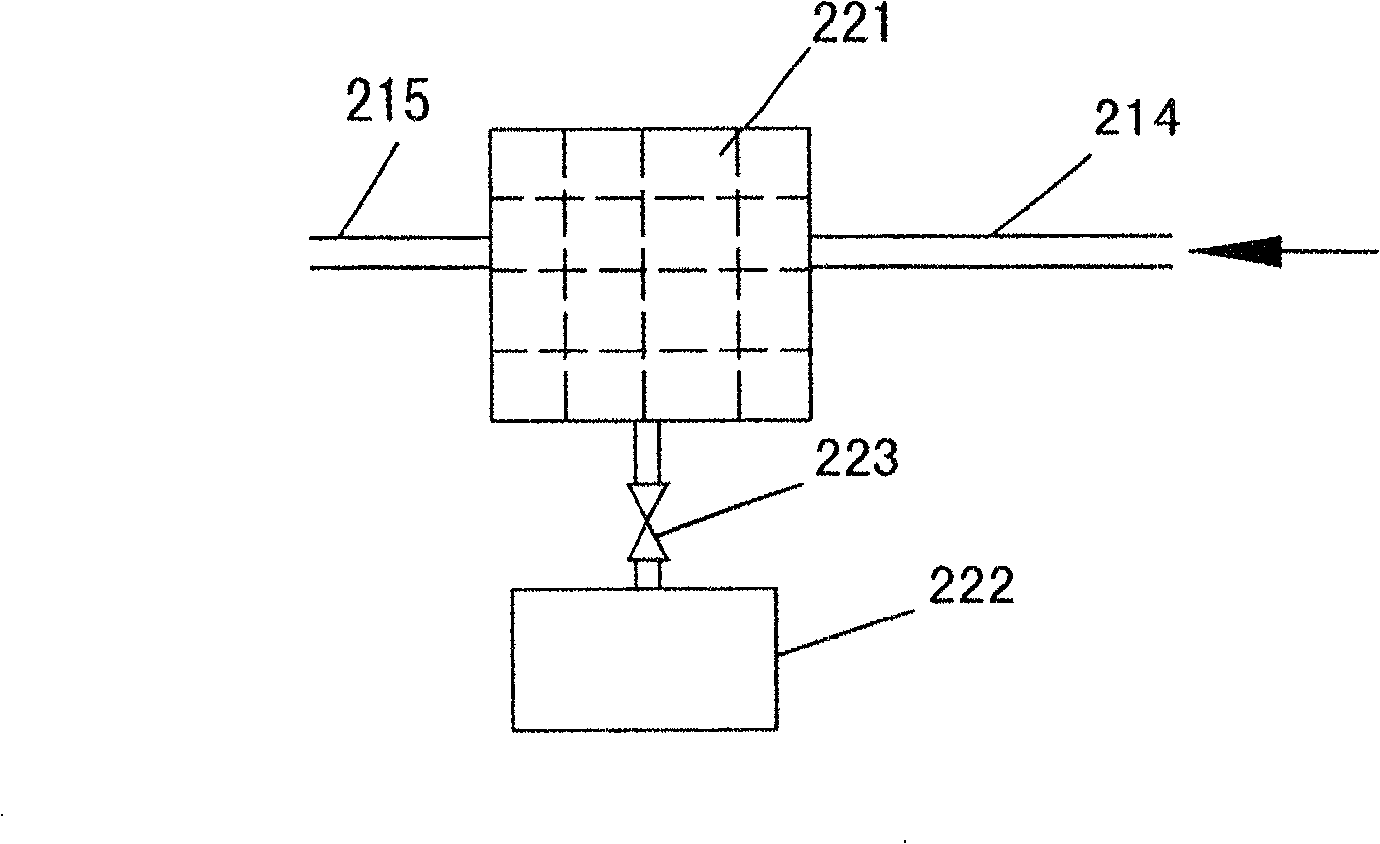

[0030] see figure 2 The acid mist collection and treatment device of the present invention includes an acid mist collection mechanism 21, an acid liquid recovery mechanism 22 for gas-liquid separation, an acid mist pretreatment mechanism 23, an acid mist treatment mechanism 24, a fan 25, an exhaust chimney 26 and corresponding connections pipeline. The acid mist collection mechanism 21 is connected to the rinse tank 31 and the pickling tank 32 to collect the acid mist generated by the rinse tank 31 and the pickling tank 32 respectively, and the acid liquid recovery mechanism 22 for gas-liquid separation is connected to the acid mist collection mechanism 21. For the separation and recovery of acid liquid, the acid mist pretreatment mechanism 23 is arranged before the acid mist treatment mechanism 24 to pretreat the acid mist entering the acid mist treatment mechanism 24, and the acid mist treatment mechanism 24 washes and absorbs the acid mist, and the fan 25 It is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com