Sludge decrement type biomembrane piled ball packing, preparation method and application

A technology of sludge reduction and ball packing, applied in the direction of sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of increased annual sludge production, large sludge volume, and no environmental pollution , to achieve the effects of film formation, stable operation, flexible construction scale, and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

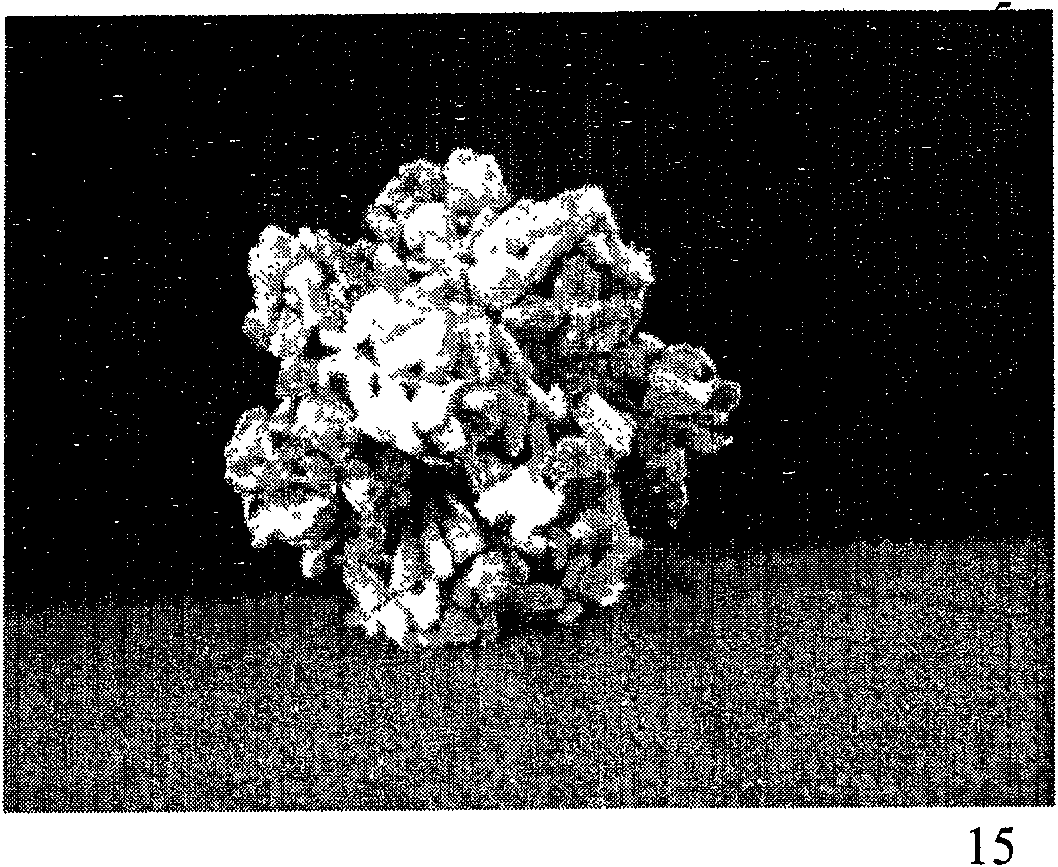

Image

Examples

Embodiment 1

[0036] 1) Select the natural stone material commonly used in the market for ordinary building paving—limestone for bonding, and use a crusher to crush the selected natural stone material into particles with a diameter of about 0.7cm;

[0037] 2) Generally, after crushing, there is no oil stain or other pollutants on the surface of this kind of stone, and only the mud dust and debris generated by the crushing operation accumulate. Soak it in 1% dilute hydrochloric acid solution for about 5 hours, then wash it with tap water and dry it for later use;

[0038] 3) Use the adhesive epoxy resin 6101 and the epoxy resin curing agent polyamide T31, mix them at a ratio of 6:1, stir them thoroughly until the adhesive is opaque and milky white, and set aside;

[0039] 4) Sub-spheres with a diameter of 4 cm are bonded. Fill the spherical mold with an inner diameter of 4cm with the stone particles treated in step 1), and then immerse it in the adhesive prepared in step 3), take it out afte...

Embodiment 2

[0042] The difference from Example 1 is that the natural stone selected for bonding is conglomerate, and the adhesive epoxy resin 828 and the epoxy resin curing agent polyamide 650 are mixed in a ratio of 8:1, and the remaining production methods and steps Same as Example 1.

Embodiment 3

[0044] The difference from Example 1 is that the natural stone selected for bonding is breccia, the adhesive epoxy resin 618 and the epoxy resin curing agent polyamide 300 are mixed in a ratio of 8:1, and the rest of the production methods are the same as Step is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com