Process for recovery of excess energy of flue gas from converter

A technology for steelmaking converter and waste energy recovery, which is applied to the improvement of process efficiency, furnace and furnace components, etc., can solve the problems of difficult efficient utilization of steam, gas explosion, limited waste heat recovery, etc., to reduce the possibility of gas explosion, The effect of improving dust removal efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below by way of examples, but not limited to examples.

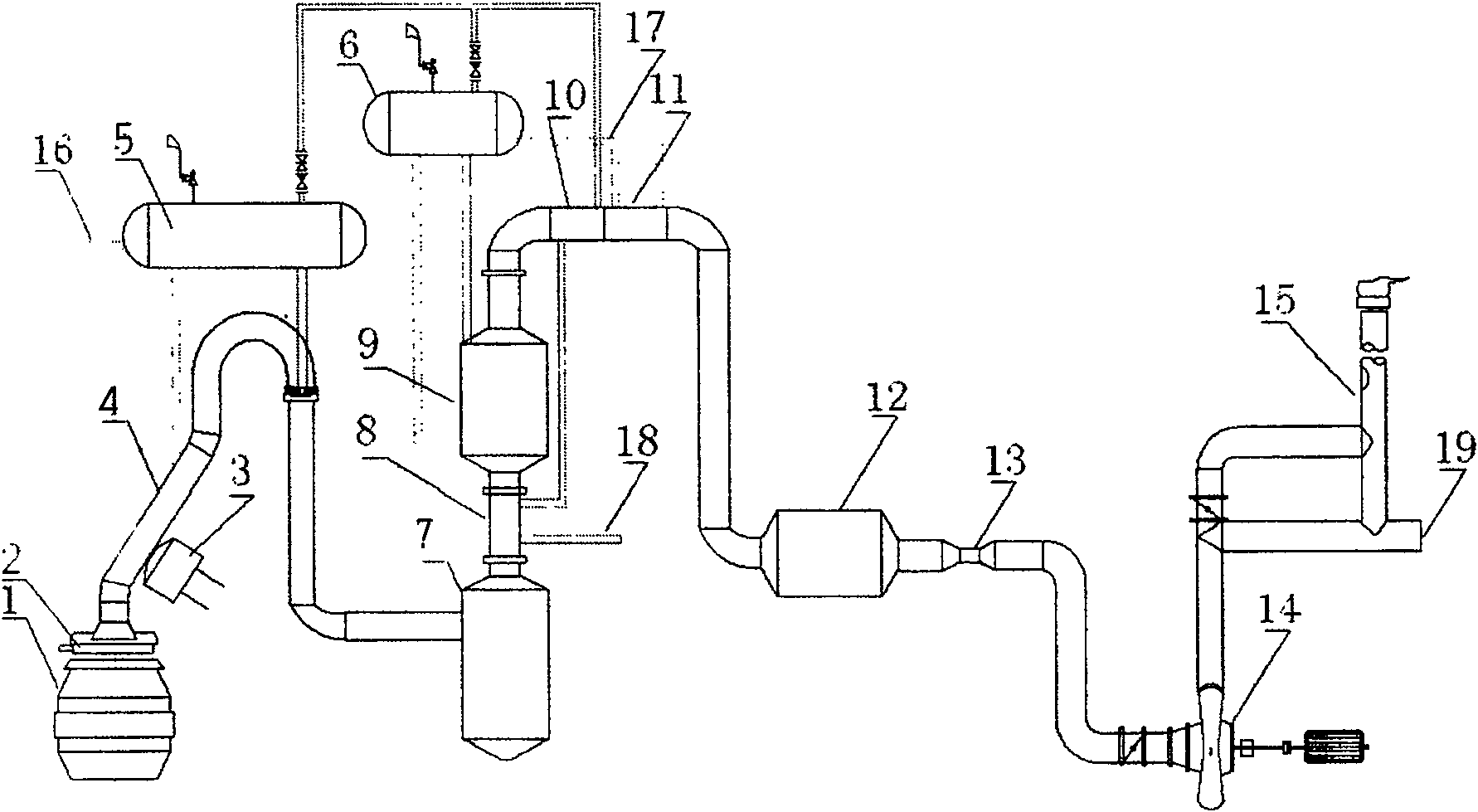

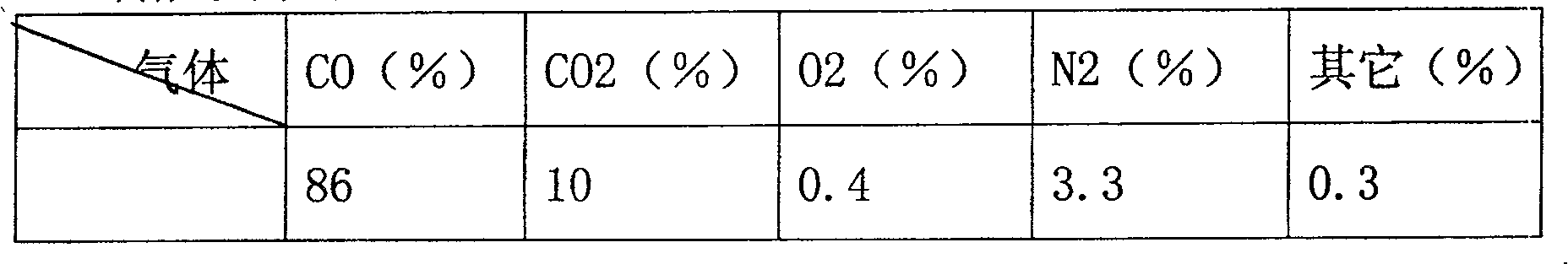

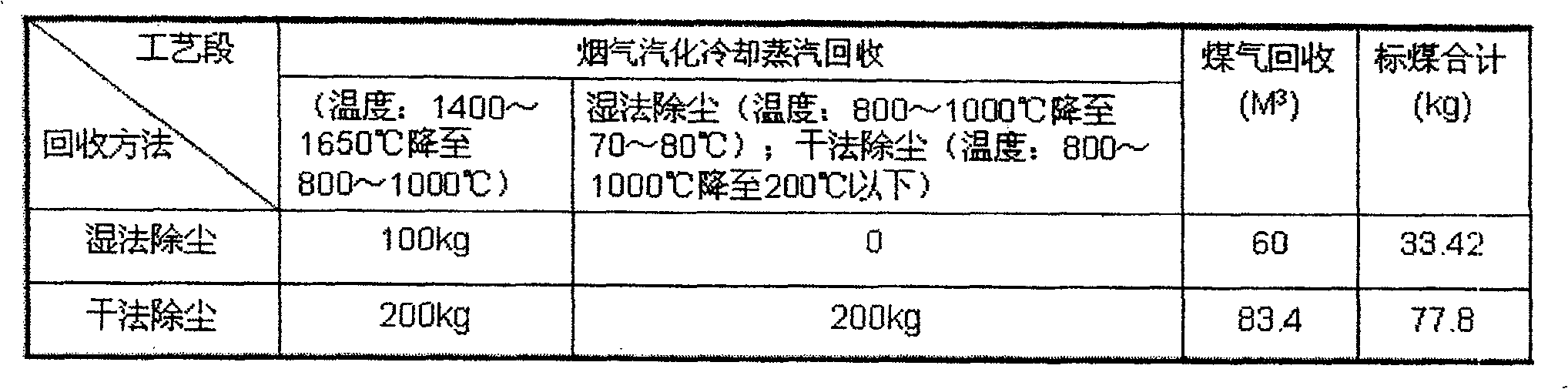

[0018] Take the No. 6 steelmaking converter flue gas dry dust removal and residual energy recovery device of Kunming Steel No. 3 Steelmaking Plant as an example.

[0019] Converter technical parameters:

[0020] 1. Converter nominal volume: 50t

[0021] 2. Average smelting cycle: 33min

[0022] 3. Oxygen blowing time: 14~17min

[0023] 4. Maximum furnace gas volume: 35600m 3 / h (standard condition)

[0024] 5. The temperature of the furnace gas outlet entering the fume hood: combustion period: 1400 ℃ ~ 1650 ℃

[0025] Recovery period: 1200℃~1400℃

[0026] 6. Initial dust concentration: 80~150g / Nm 3 (standard condition)

[0027] 7. Dispersion of smoke and dust:

[0028] particle size / um

<0.5

0.5-1

1-2

2-10

10-40

>40

Combustion method / %

50

45

5

Unburned method / %

30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com