Double separation method and double separation system for oxygen gas and nitrogen gas

A separation method, gas separation technology, applied in separation methods, nitrogen purification/separation, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

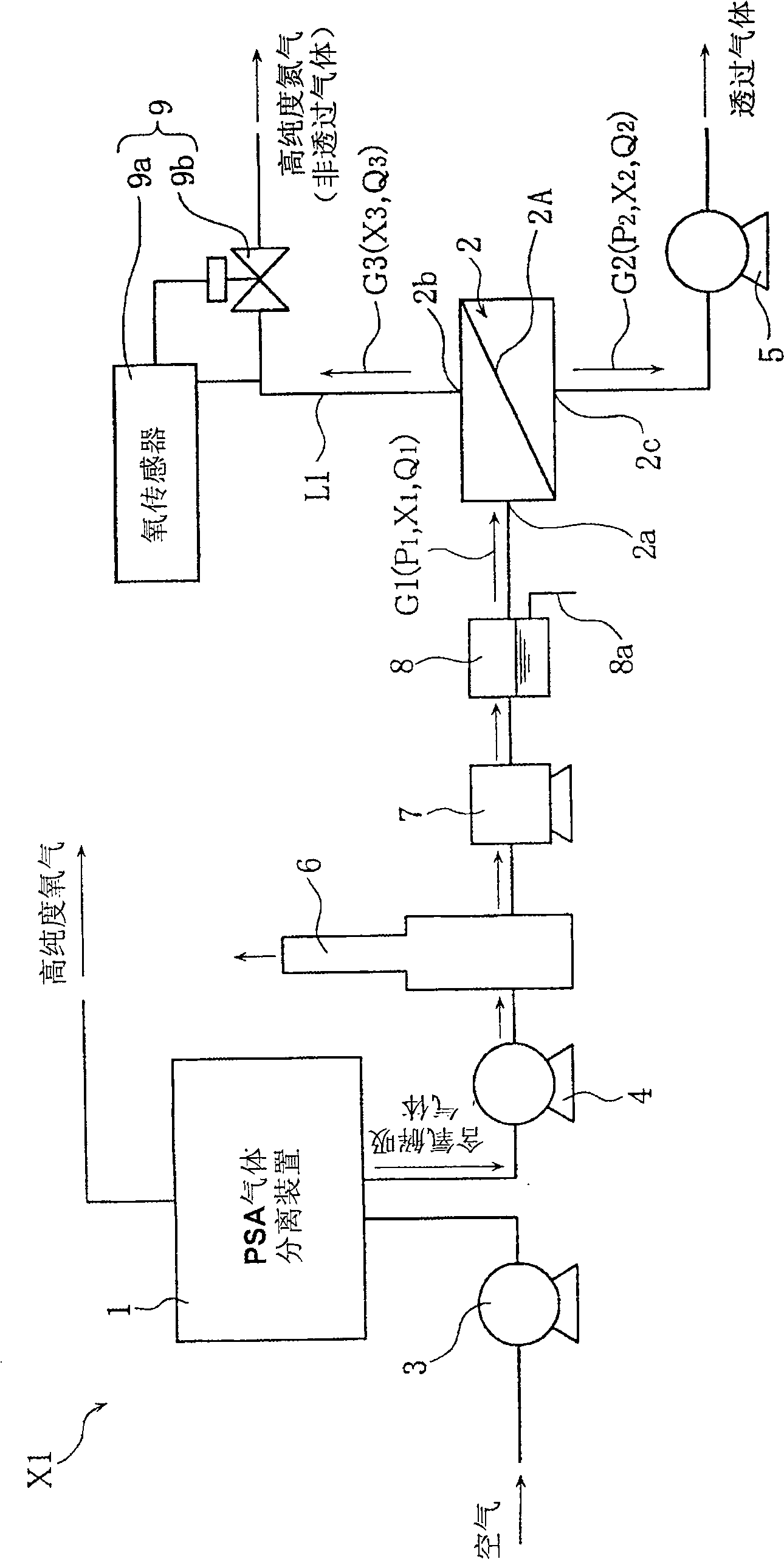

[0031] figure 1 An oxygen-nitrogen parallel separation system X1 according to the first embodiment of the present invention is shown. The oxygen-nitrogen parallel separation system X1 includes a pressure swing adsorption (PSA) gas separation device 1, a membrane gas separator 2, a raw gas supply device 3, pumps 4 and 5, a silencer (silencer) 6, a compressor 7, a gas-liquid The separator 8, the oxygen concentration control mechanism 9, and the piping connected to the above-mentioned devices form a parallel separation of oxygen-enriched gas and nitrogen-enriched gas from air (raw material gas containing oxygen-nitrogen), and implement gas separation including pressure swing adsorption Process, compression process, and the structure of the oxygen-nitrogen parallel separation method of the membrane gas separation process.

[0032] The PSA gas separation device 1 is equipped with at least one adsorption tower (not shown) filled with an adsorbent mainly used for preferentially ads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com