Lithium ion polymer electrolyte film and manufacturing method of lithium ion cell comprising the film

An electrolyte membrane and polymer technology, which is applied in the field of rechargeable lithium-ion batteries, can solve the problems of cycle performance and high temperature performance that cannot meet the requirements, cannot meet the application, and low conductivity, and achieve good mechanical properties, improved uniformity, and conductivity. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

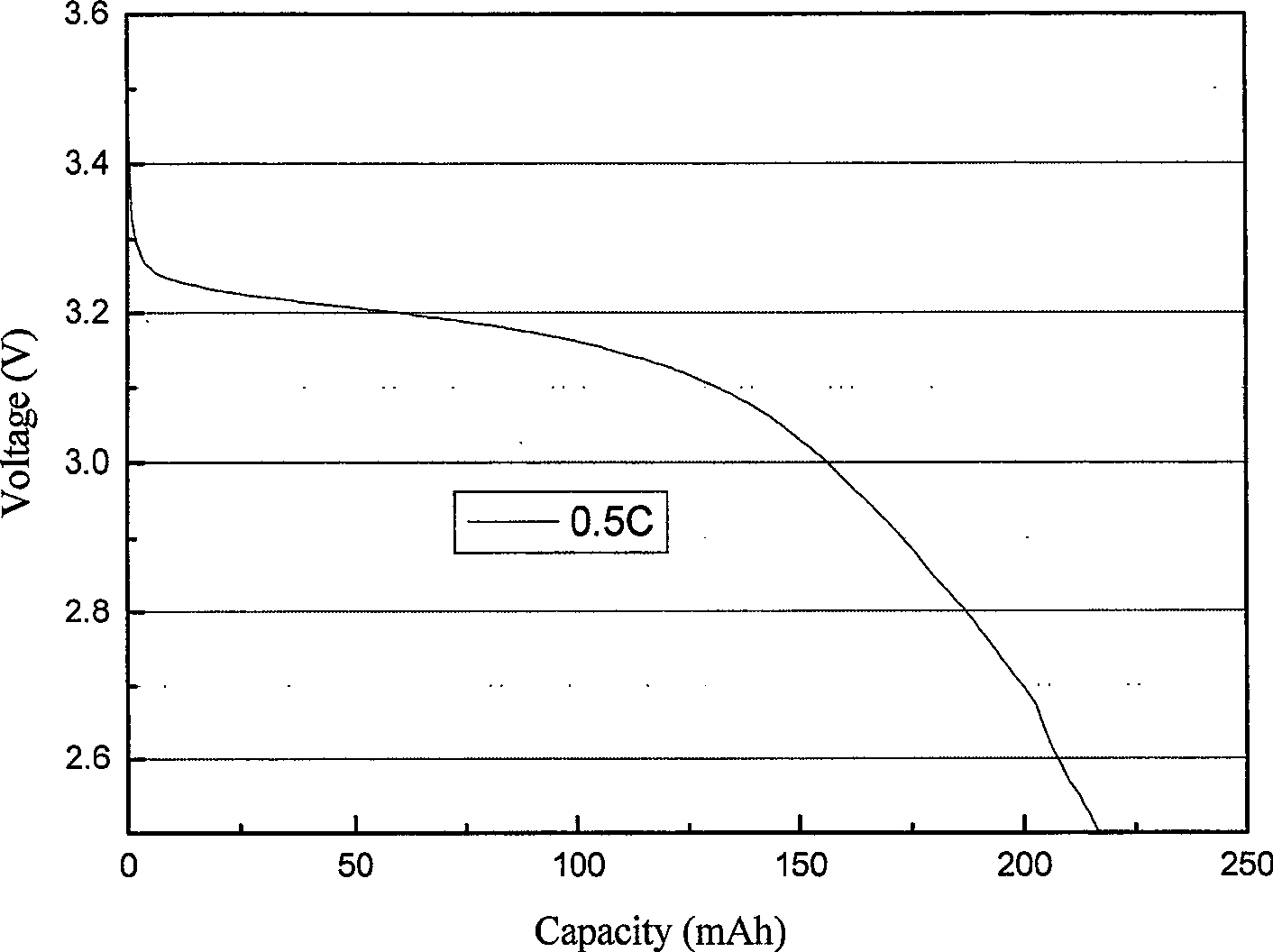

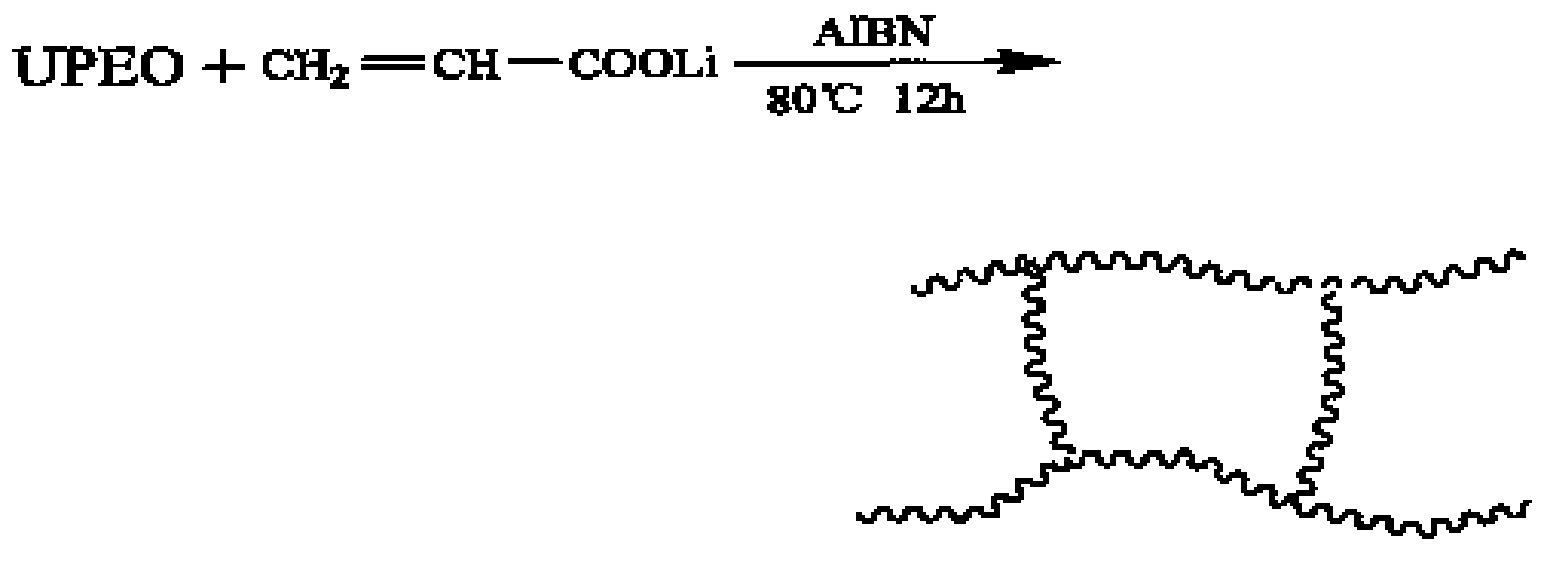

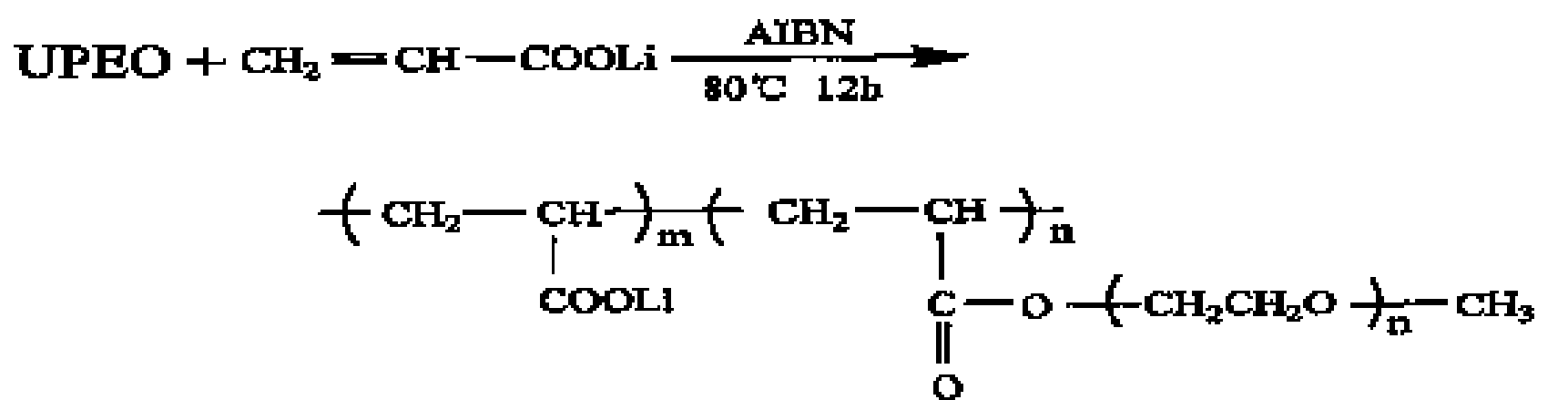

[0051] Embodiment 1: a kind of lithium ion polymer electrolyte membrane, it is by the PEO macromonomer that average molecular weight is 600, lithium acrylate small monomer, azobisisobutyronitrile with PEO macromonomer: lithium acrylate small monomer: Azobisisobutyronitrile = 1:50:0.05 molar ratio of the free radical copolymerization reaction of the high amorphous phase polymer matrix, and LiBF under nitrogen atmosphere 4 , Li-β-Al 2 o 3 After the nano-powder is compounded to form a lithium-ion polymer electrolyte, the electrolyte membrane is made by casting, in which LiBF 4 , Li-β-Al 2 o 3 The weight percentages of the nanometer powder in the lithium ion polymer electrolyte are 10% and 20% respectively.

[0052] A method for preparing the above-mentioned lithium ion polymer electrolyte membrane:

[0053] (1) Preparation of polyoxyethylene macromonomer Prepare polyethylene glycol (PEG, average molecular weight 600), triethylamine, and acryloyl chloride at a molar ratio of ...

Embodiment 2

[0063] Embodiment 2: a kind of lithium ion polymer electrolyte membrane, it is by the PEO macromonomer that average molecular weight is 600, lithium acrylate small monomer, azobisisobutyronitrile with PEO macromonomer: lithium acrylate small monomer: Azobisisobutyronitrile = 1:80:0.08 molar ratio of the free radical copolymerization reaction of the high amorphous phase polymer matrix, in the atmosphere of nitrogen and LiBF 4 , Li-β-Al 2 o 3 After the nano-powder is compounded to form a lithium-ion polymer electrolyte, the electrolyte membrane is made by casting, in which LiBF 4 , Li-β-Al 2 o 3 The weight percentages of the nanometer powder in the lithium ion polymer electrolyte are 10% and 15% respectively.

[0064] A method for preparing the above-mentioned lithium ion polymer electrolyte membrane:

[0065](1) Preparation of polyoxyethylene macromonomer Prepare polyethylene glycol monomethyl ether (mPEG, average molecular weight 600), triethylamine, and acryloyl chloride...

Embodiment 3

[0074] Embodiment 3: a kind of lithium ion polymer electrolyte membrane, it is to use azobisisobutyronitrile as initiator, carries out radical copolymerization with PEO macromonomer and lithium acrylate monomer, wherein PEO macromonomer: lithium acrylate monomer Body: the molar ratio of azobisisobutyronitrile is 1:100:0.11, then add 30wt% Li-β-Al to the obtained copolymer 2 o 3 After the nano-powder is compounded into a lithium-ion polymer electrolyte, it is flow-cast to form a film under a nitrogen atmosphere.

[0075] A method for preparing the above-mentioned lithium ion polymer electrolyte membrane:

[0076] (1) Preparation of polyoxyethylene macromonomer Prepare polyethylene glycol (PEG, average molecular weight 400), triethylamine, and acryloyl chloride (AC) at a molar ratio of 1:1.8:2.8, and stir in a magnetic stirring, water bath Under the reaction conditions of a heating temperature of 35°C, add polyethylene glycol and triethylamine to the toluene solvent in the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com