Electrochemical corrosion processing method for micro fine cylindrical group electrode

A technology of corrosion processing and group electrodes, applied in electric processing equipment, processing electrodes, electrode manufacturing, etc., can solve problems such as low processing quality, high manufacturing cost, and complicated process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

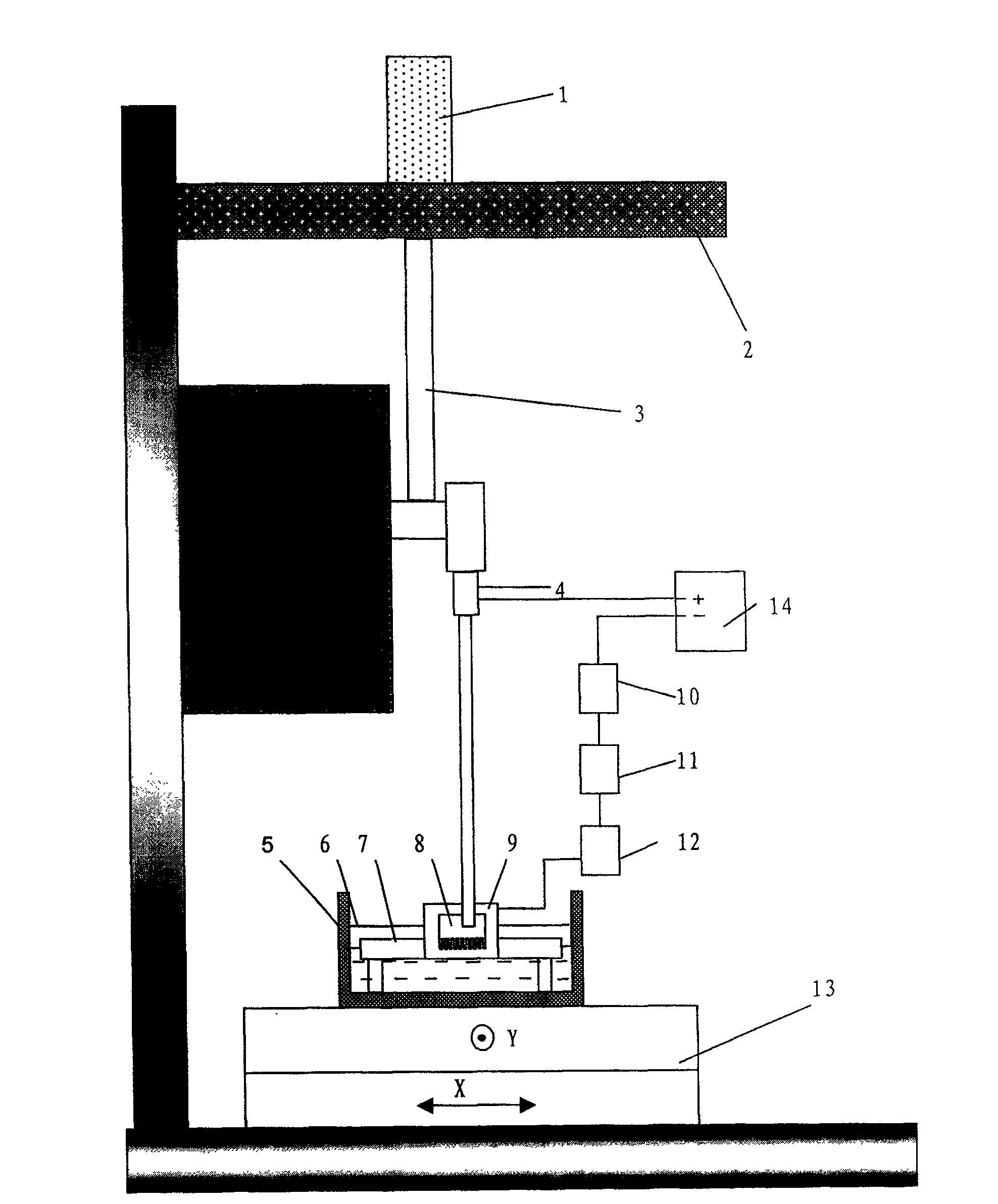

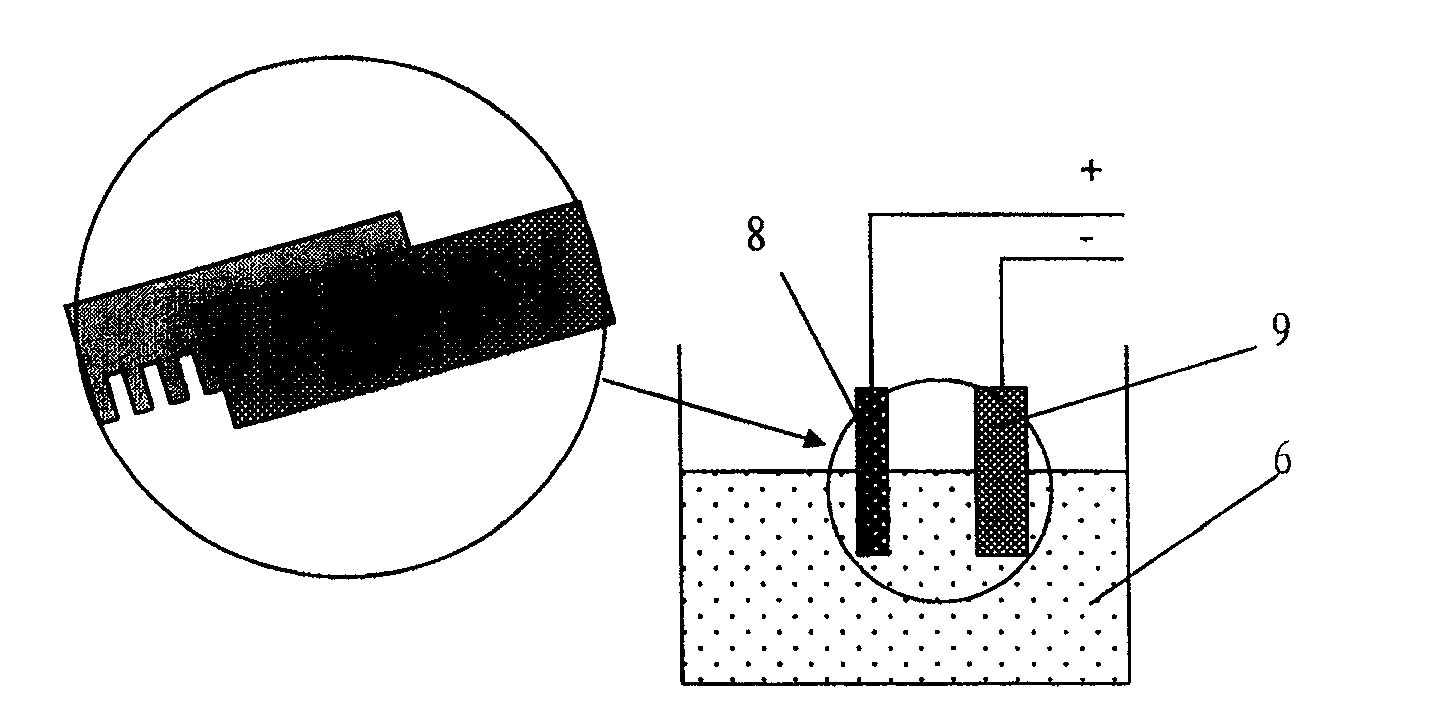

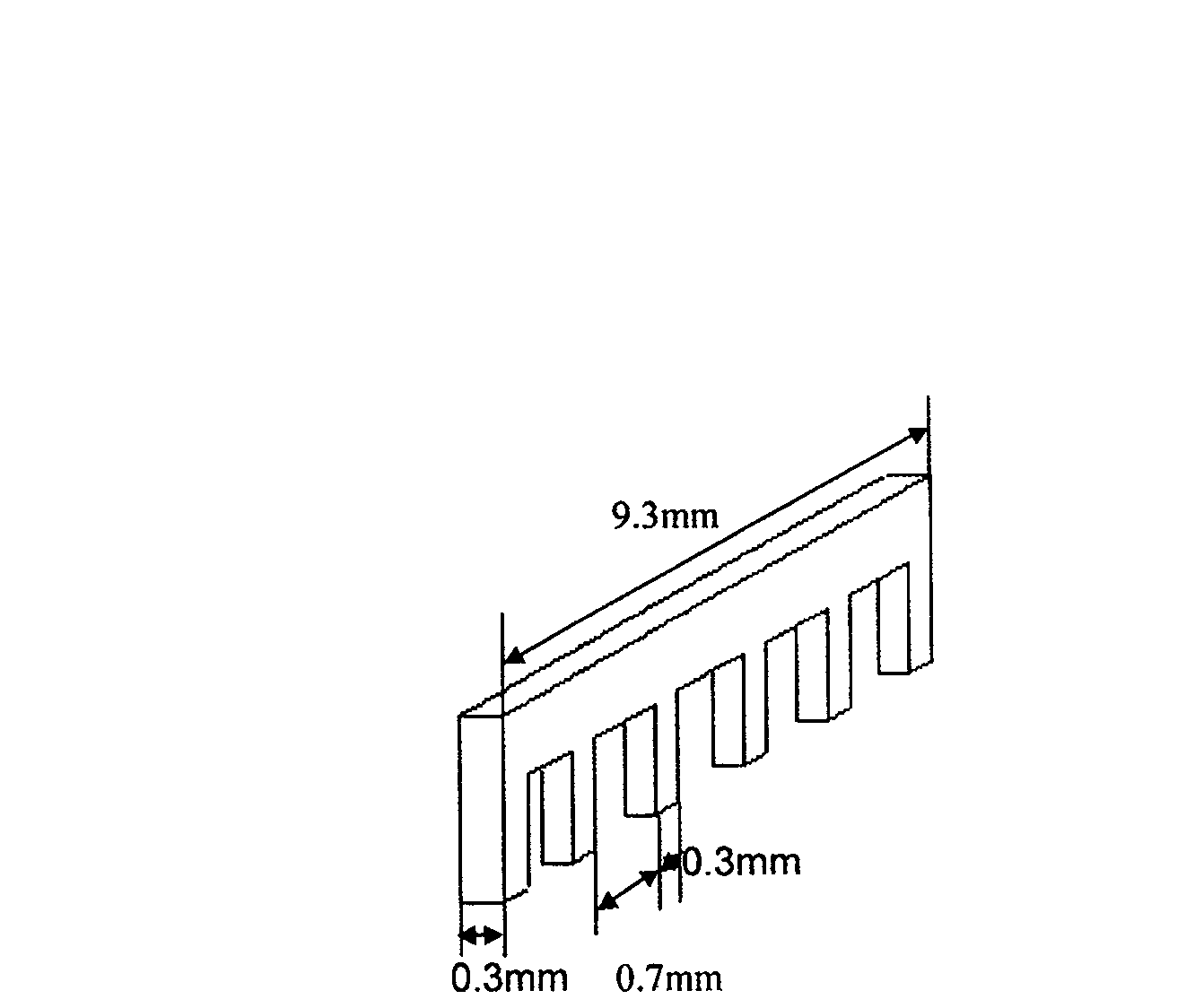

[0054] Such as figure 1 As shown, the electrochemical corrosion processing of micro-cylindrical group electrodes is carried out on a CNC machine tool that can realize three-degree-of-freedom movement including the machine tool body 2, the CNC workbench 13, and the z-axis 3; the electrochemical corrosion processing system is installed on the CNC workbench 13 The electrolyte tank 5 on the top, the tool cathode 9 fixed in the electrolyte tank by the cathode installation fixture 7, the workpiece anode 8 immersed in the electrolyte by the anode installation fixture 4, and the ammeter 10, the data acquisition card 11, the computer 12, the direct current The power supply 14 is composed.

[0055] The relative position between the workpiece anode 8 and the tool cathode 9 is adjusted by the movement of the numerical control workbench 13 to make it reach the expected design state. The depth of the workpiece anode 9 immersed in the electrolyte is controlled by the up and down movement of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com