Composite resistivity silicon scale inhibitor for preventing silicon dioxide dirt deposition in industrial water conditioning system

A technology for silica scale, industrial water treatment, applied in water/sludge/sewage treatment, descaling and water softening, chemical instruments and methods, etc. Degradation, water pollution and other problems, to achieve obvious synergistic effect of blocking silicon, less total dosage, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

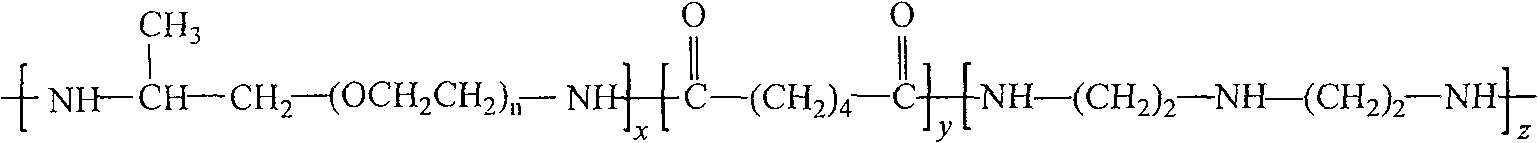

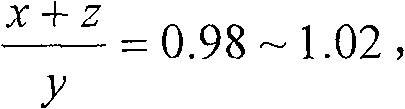

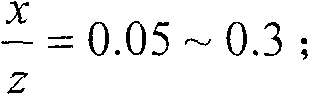

[0044] Example 1 This example is the preparation of adipic acid / amino-terminated polyether / diethylenetriamine copolymer

[0045] Add 34.5g of amino-terminated polyether D230 and 87.6g of diethylenetriamine into a four-necked flask equipped with a stirring, thermometer, ventilation tube, steam condenser and steam trap, stir well and then slowly add 70g of Deionized water, after stirring for 10 minutes, add 146g of adipic acid in batches while stirring, and control the temperature <70°C. After adding adipic acid, feed nitrogen, place in an oil bath and start heating to 180°C, when the temperature rises to 120°C~125°C, condensed water begins to appear, which is collected through a steam condenser and a steam trap The condensed water was collected, and the temperature was continued to rise until the temperature of the reaction liquid reached 180° C., and the reaction was carried out at 180° C. for 4 hours to obtain a yellow viscous substance. Then the reaction solution was cooled...

Embodiment 2

[0046] Embodiment 2 This embodiment is the static silicon scale inhibition experiment of composite scale inhibitor

[0047] Preparation of composite silicon and scale inhibitor: adipic acid / amino-terminated polyether / diethylenetriamine copolymer (AA / ATPEs / EDETA) with a solid content of 40% and polyaspartic acid with a solid content of 40% Sodium (PASP) is uniformly mixed according to the effective mass ratio of adipic acid / amino-terminated polyether / diethylenetriamine copolymer and sodium polyaspartate at a ratio of 10:1 to make a composite silicon barrier with a solid content of 40%. Inhibitor.

[0048] The prepared compound antiscalant was tested for the performance test of static silica scale inhibition, and the experimental results are shown in Table 2.

Embodiment 3

[0049] Example 3 This example is the static silicon scale inhibition experiment of composite scale inhibitor

[0050] Preparation of composite silicon and scale inhibitor: adipic acid / amino-terminated polyether / diethylenetriamine copolymer (AA / ATPEs / EDETA) with a solid content of 40% and polyaspartic acid with a solid content of 40% Sodium (PASP) is uniformly mixed according to the effective mass ratio of adipic acid / amino-terminated polyether / diethylenetriamine copolymer and sodium polyaspartate at an effective mass ratio of 8:1 to make a composite silicon barrier with a solid content of 40%. Inhibitor.

[0051] The prepared compound antiscalant was tested for the performance test of static silica scale inhibition, and the experimental results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com