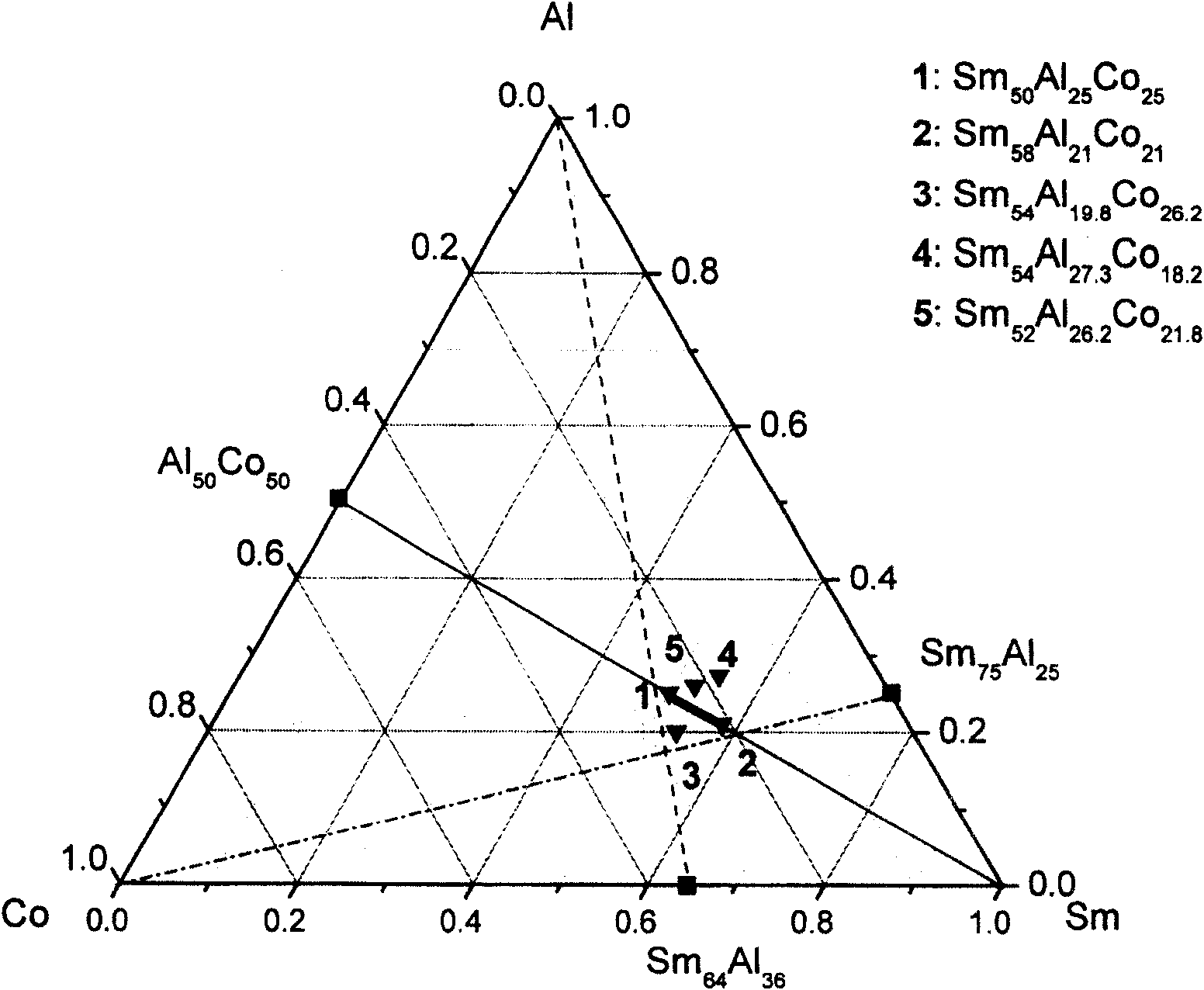

Sm-Al-Co system Sm base ternary block amorphous alloy

A kind of amorphous alloy, 1.sm-al-co technology, applied in the field of Sm-Al-Co bulk amorphous alloy, can solve the problem of easy oxidation burning and volatilization, difficult composition control, and easy deviation of alloy composition from amorphous composition and other problems, to achieve the effect of simple alloy components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

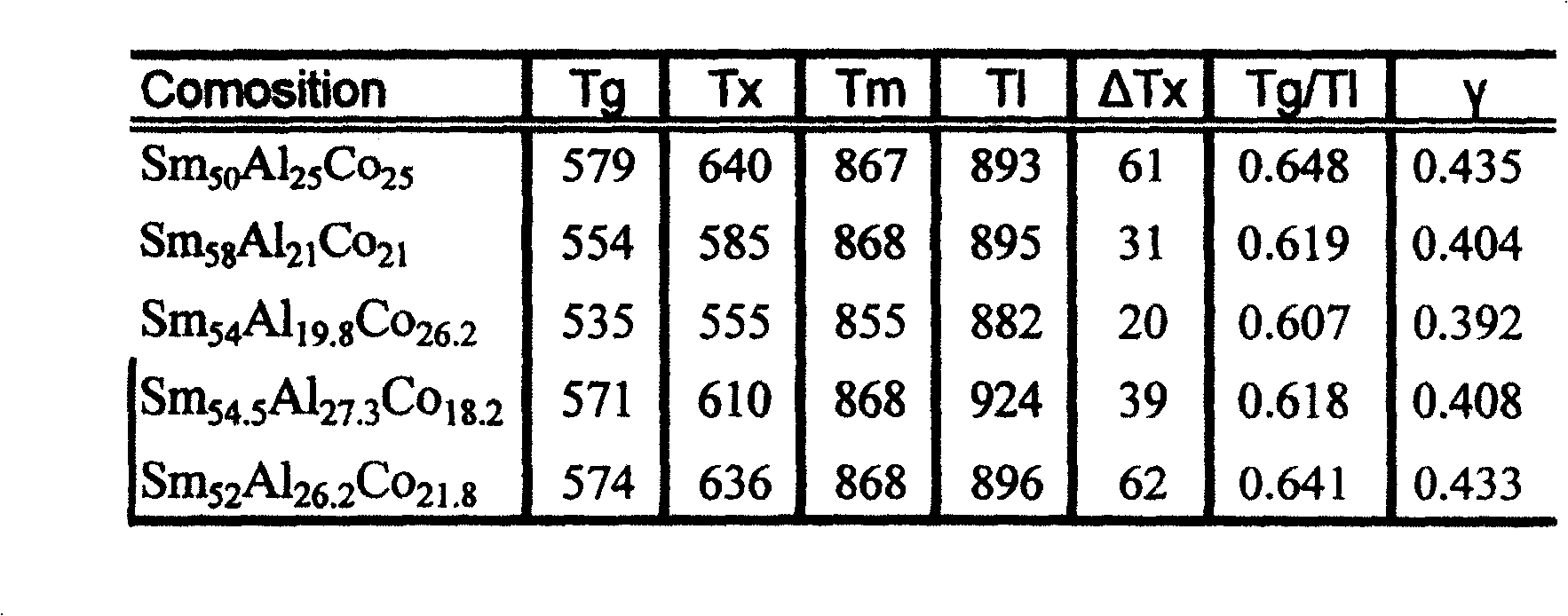

[0035] Embodiment one, Sm 50 al 25 co 25 Preparation of Bulk Amorphous Alloy and Its Properties Test

[0036] The first step, the weighing of the composition ratio

[0037] According to the atomic percentage in the design composition, it is converted into a weight percentage wt.%, and the pure metal Sm, Al, and Co raw materials with a purity of 99.9% are weighed in proportion for use; 2% more Sm has been added in advance for weighing. Compensation for volatilization during alloy melting;

[0038] The second step, Sm 50 al 25 co 25 Melting of ternary alloy ingot

[0039] The mixture of Al, Co and rare earth metal Sm is placed in a water-cooled copper crucible of a non-consumable arc melting furnace, and melted under the protection of argon. First, the vacuum is evacuated to 10 -2 Pa, then filled with argon until the pressure is 0.06MPa, the melting current density range is 140A / cm 2 , after melting, continue to smelt for 10 seconds, turn off the power, let the alloy co...

Embodiment 2

[0046] Embodiment 2, Sm 58 al 21 co 21 Preparation of Bulk Amorphous Alloy and Its Properties Test

[0047] The first step, the weighing of the composition ratio

[0048] According to the atomic percentage in the design composition, it is converted into a weight percentage wt.%, and the pure metal Sm, Al, and Co raw materials with a purity of 99.9% are weighed in proportion for use; 2% more Sm has been added in advance for weighing. compensate for its volatilization;

[0049] The second step, Sm 58 al 21 co 21 Melting of ternary alloy ingot

[0050] The smelting method of alloy ingot adopts the method for the second step in the embodiment one to carry out; Vacuumizing is 10 -2 Pa, filled with argon gas pressure is 0.08MPa, the current density used for melting is 120A / cm 2 , repeated smelting 3 times to obtain a ternary alloy ingot with uniform composition;

[0051] The third step, Sm 58 al 21 co 21 Composition inspection of ternary alloy ingot

[0052] The inspec...

Embodiment 3

[0059] Embodiment three, Sm 54 al 19.8 co 26.2 Bulk amorphous alloy preparation

[0060] The first step, the weighing of the composition ratio

[0061] According to the atomic percentage in the design composition, it is converted into a weight percentage wt.%, and the pure metal Sm, Al, and Co raw materials with a purity of 99.9% are weighed in proportion for use; 2% more Sm has been added in advance for weighing. compensate for its volatilization;

[0062] The second step, Sm 54 al 19.8 co 26.2 Melting of ternary alloy ingot

[0063] The smelting method of alloy ingot adopts the method for the second step in the embodiment one to carry out; Vacuumizing is 10 -2 Pa, filled with argon gas pressure is 0.07MPa, the current density used for melting is 130A / cm 2 , repeated smelting 3 times to obtain a ternary alloy ingot with uniform composition;

[0064] The third step, Sm 54 al 19.8 co 26.2 Composition inspection of ternary alloy ingot

[0065] The inspection method o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com