Method of taking zirconium oxide balls as ball-milling medium for soft magnetic ferrite material

A technology of soft magnetic ferrite and zirconia balls, which is applied in the field of electronic ceramics, can solve the problems of long milling time, material particle size not meeting the requirements, and high cost, so as to reduce ball milling time, reduce component deviation, and save manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

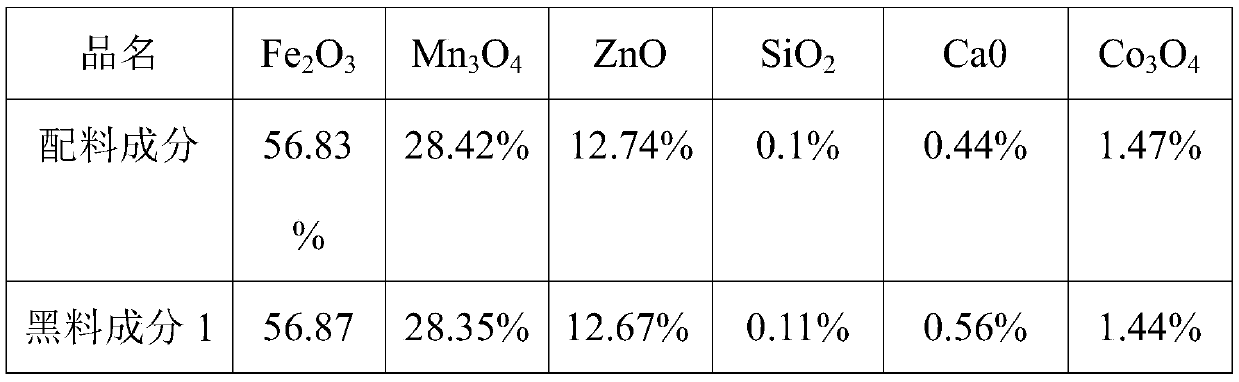

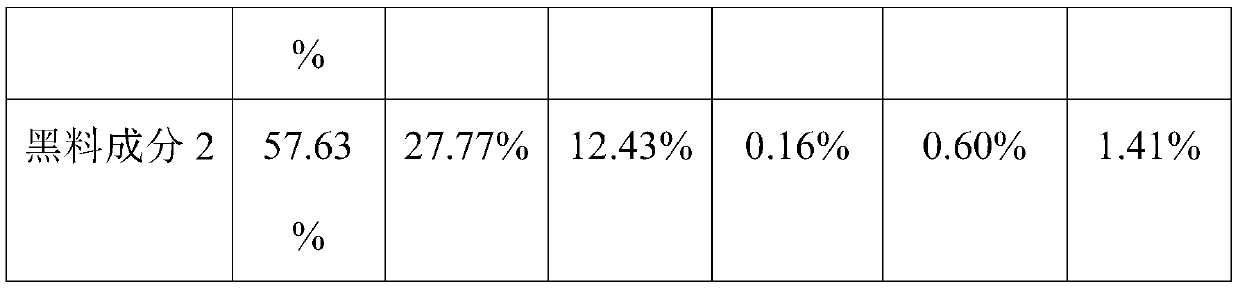

Embodiment 1

[0032] Weigh each component by mass percentage, 58% of ferric oxide, 29% of trimanganese tetroxide, and the balance is zinc oxide; the above main raw materials are weighed and mixed, and an appropriate amount of pure water is added, and the weight ratio of water and raw materials is 1:1.5; add 1.5wt% dispersant, put zirconia balls into the ball milling medium, the total weight ratio of zirconia balls and main raw materials is 5:1; start ball milling, the ball milling time is 3h, wait for the raw materials to disperse into a suitable particle size After mixing the slurry, take it out and dry it for later use; take out a small amount of the dried material for component detection (the test result is marked as red material component 1); pre-fire the dried slurry at a sintering temperature of 950°C; The sintered material is added with additives for ball milling; the mass fraction of the additives in the calcined material is: 0.1% of silicon dioxide; 0.8% of calcium carbonate; 1.5% o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com