Low-temperature thermal insulation paper preparation method

A low-temperature thermal insulation and multi-layer thermal insulation technology, applied in papermaking, textile and papermaking, synthetic cellulose/non-cellulose material pulp/paper, etc., can solve the problems of affecting product performance, increasing outgassing rate, and high comprehensive cost. Achieve long service life, increase contact thermal resistance, and good profiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

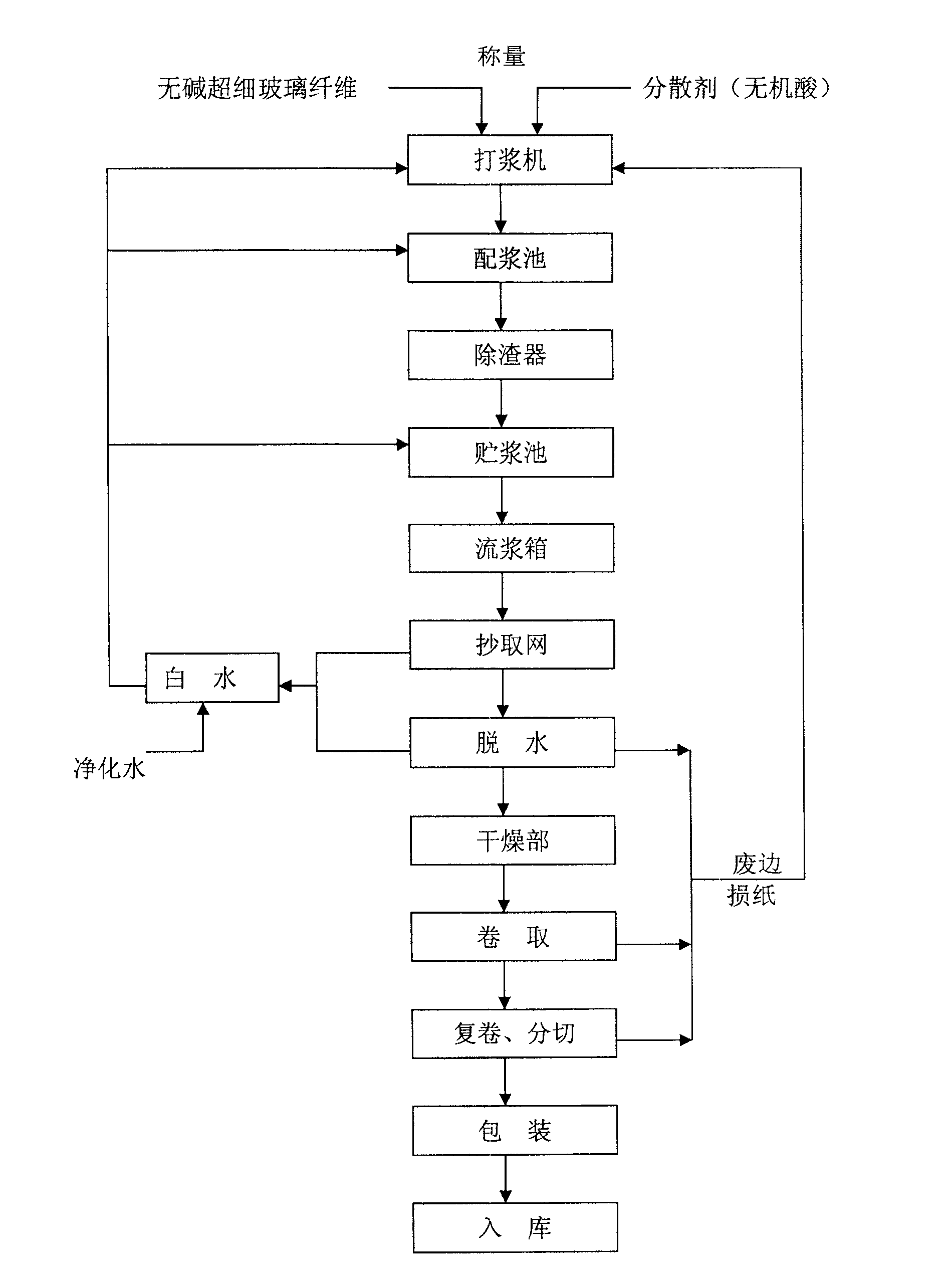

[0033] The preparation of embodiment 1 low temperature insulation paper (referring to figure 1 )

[0034] (1) Add 100Kg of 49°SR (fiber diameter 0.1-1.0μm) ultra-fine alkali-free glass fiber into the beater and dilute it to 1.0% with water, add sulfuric acid to adjust the pH value to 2.5, and put it away after the fibers are all dispersed into single strands into the mixing pool;

[0035] (2) Continue to dilute the glass fiber put into the slurry mixing tank to 0.1% with white water, and add sulfuric acid to adjust the pH value to 2.5, and after stirring evenly, use a pump to send the slurry to the slurry storage tank after being treated by a conical slag remover;

[0036] (3) Pump the slurry from the slurry tank to the headbox, dilute it with white water to 0.05% again, and then take it online, after dehydration and pressing, it enters the drying tunnel for drying, and finally after trimming, stick it to the cylinder and coil it into rolls .

[0037] The above-mentioned fi...

Embodiment 2

[0039] Example 2 Preparation of Low Temperature Thermal Insulation Paper

[0040] (1) Add 40Kg of 49°SR (fiber diameter 0.1-1.0μm) alkali-free glass fiber into the beater, dilute it to 0.5% with water, add sulfuric acid to adjust the pH value to 2.5, and put the fiber into the compound after all the fibers are dispersed into a single fiber pulp pool;

[0041] Take 60Kg of 54°SR alkali-free glass fiber (fiber diameter is 0.1-1.0μm), add it into the beater, dilute it with water to a concentration of 0.5%, add sulfuric acid and adjust the pH value to 2.5, and put it into the compound after all the fibers are dispersed into single fibers. pulp pool;

[0042] (2) Continue to dilute the glass fiber put into the pulp mixing tank to 0.05% with white water, and add sulfuric acid to adjust the pH value to 2.5, and after stirring evenly, use a pump to send the slurry to the slurry storage tank after being treated by a conical slag remover;

[0043] (3) Pump the slurry from the slurry t...

Embodiment 3

[0046] Example 3 Preparation of Low Temperature Thermal Insulation Paper

[0047] (1) Put 40Kg of 49°SR (fiber diameter 0.1-1.0μm) alkali-free glass fiber into the beater and dilute it to 2.0% with water, add sulfuric acid to adjust the pH value to 3.0, and put the fiber into the compound after all the fibers are dispersed into a single fiber pulp pool;

[0048] Take 60Kg of 54°SR alkali-free glass fiber (fiber diameter is 0.1 ~ 1.0μm), add it into the beater, dilute it with water to a concentration of 2.0%, add sulfuric acid and adjust the pH value to 3.0, and put it into the compound after all the fibers are dispersed into single fibers. pulp pool;

[0049](2) Continue to dilute the glass fiber put into the slurry mixing tank to 0.5% with white water, and add sulfuric acid to adjust the pH value to 3.0, and after stirring evenly, use a pump to send the slurry to the slurry storage tank after being processed by a conical slag remover;

[0050] (3) Pump the slurry from the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com