Technique for reclaiming and utilizing product gas absorbed by molecular sieve in the separation process of neon isotope

A technology of isotope separation and molecular sieve, which is applied in the field of recovery and utilization of molecular sieve adsorption product gas, can solve the problems of packaging failure, air leakage, high impurities, etc., and achieve the effect of reducing product loss, high purification efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

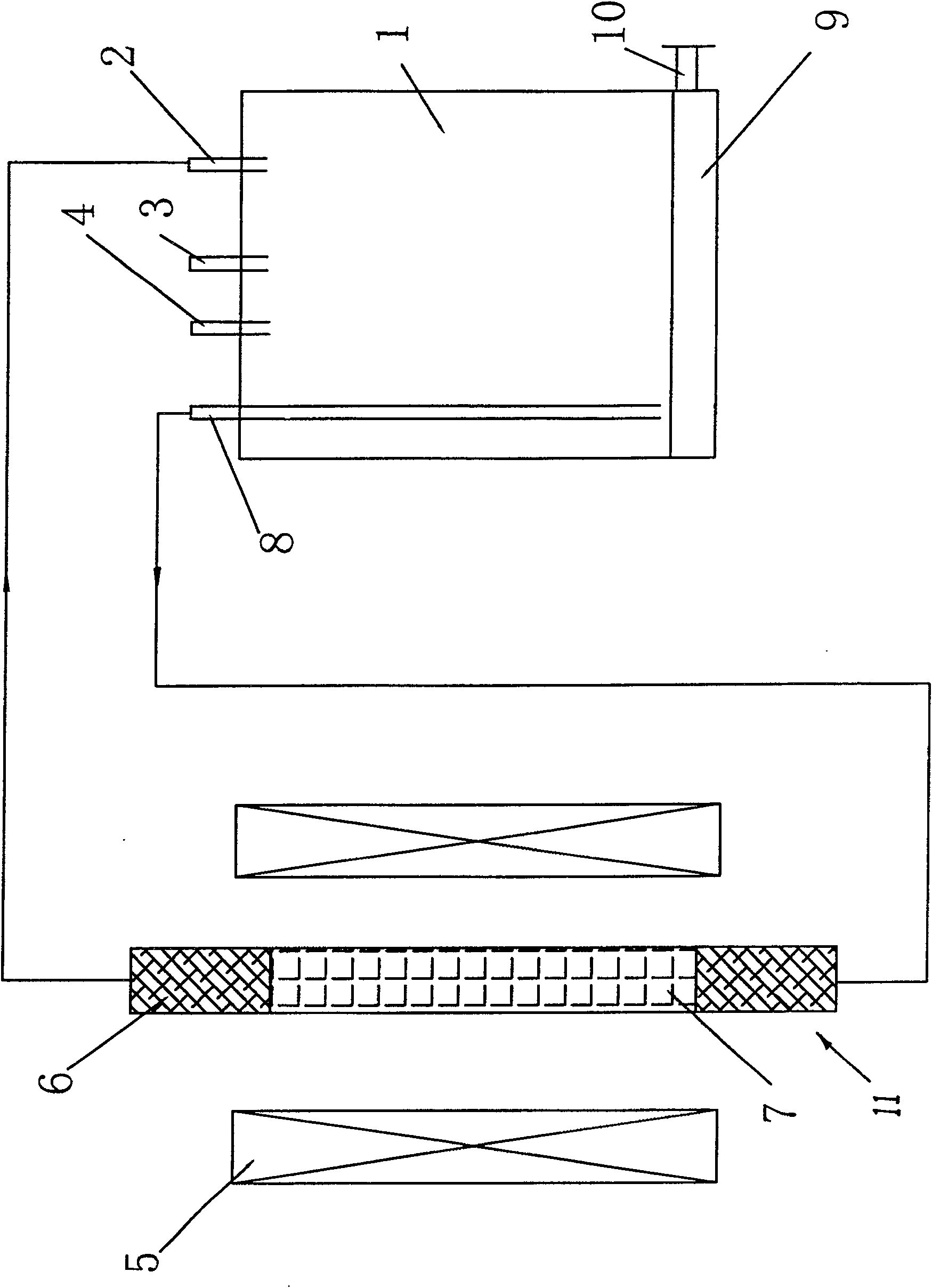

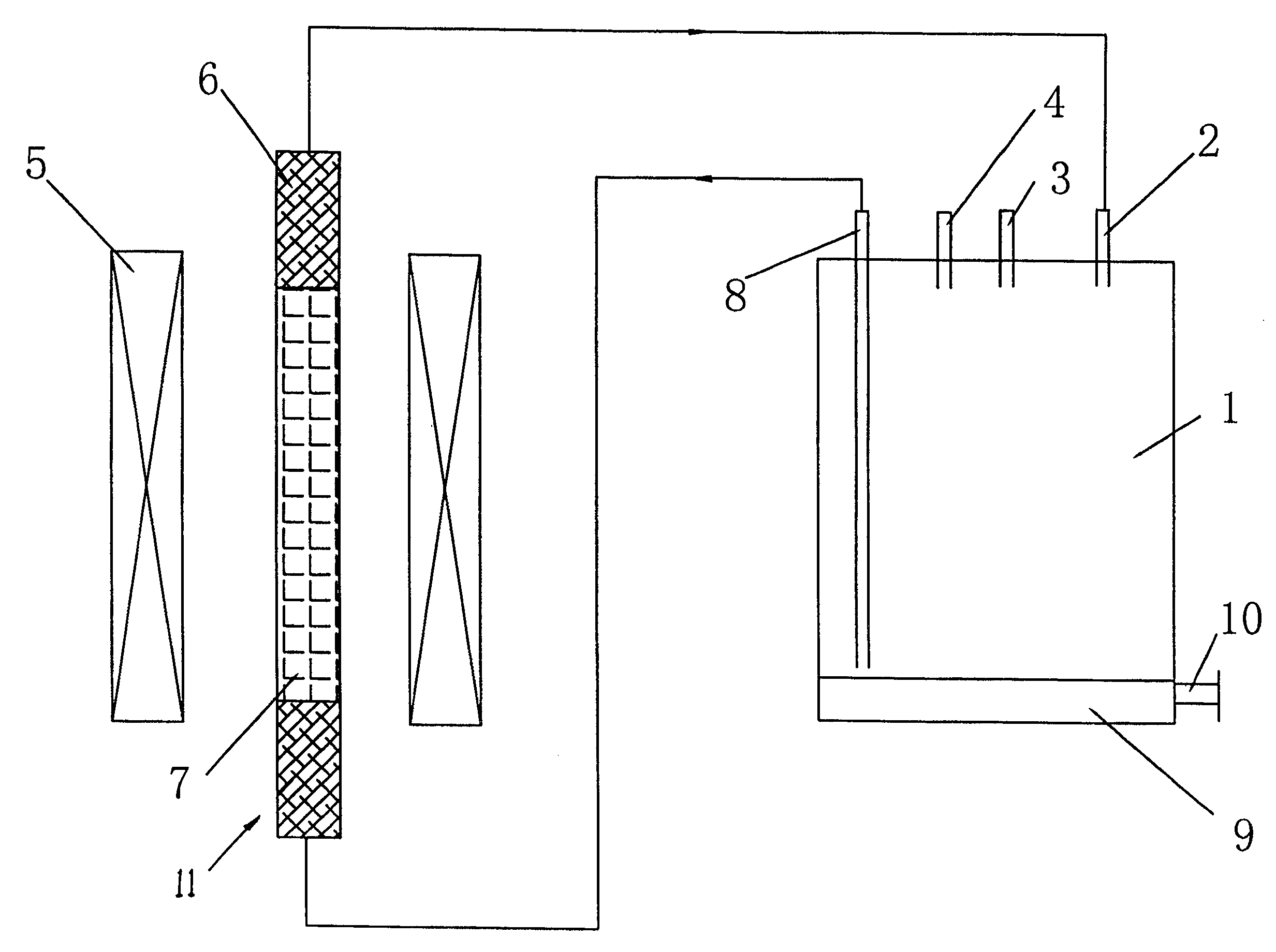

[0033] Such as figure 1 shown, a 22 The recovery and utilization process of molecular sieve adsorption product gas in Ne separation, the process includes the recovery of molecular sieve adsorption product gas, the purification of recovered gas and other process steps; the flow chart of the recovery step of molecular sieve adsorption product gas is not shown, and the recovery The equipment for the gas purification step includes a purification bottle 1, a circulating gas inlet 2, a sampling port (also a molecular sieve adsorption gas inlet and a purified product gas outlet) 3, a water injection port 4, an electric furnace 5, Cu chips 6, a sponge Ti 7, and a circulation Gas outlet 8, water (or lye) 9, drain outlet 10, purification column 11; described purification column 11 is vertically arranged, and its center is filled with sponge Ti7, and both ends are Cu chips 6, and described electric furnace 5 is arranged on On both sides of the purification column 11, the gas in the puri...

Embodiment 2

[0036] Such as figure 1 shown, a 22 The recovery and utilization process of molecular sieve adsorption product gas in Ne separation, the process includes the recovery of molecular sieve adsorption product gas, the purification of recovered gas and other process steps; the flow chart of the recovery step of molecular sieve adsorption product gas is not shown, and the recovery The equipment of the gas purification step is the same as in Example 1.

[0037] There are 9000ml99% 22 The neon isotopic gas with a Ne purity of 95% is purified on a purification column equipped with a 400mm sponge Ti, with 100mm Cu chips on the upper and lower sides, and an inner diameter of 10mm. After 24h, the purity reached 98%, and 99% after 48h. 8600ml99% available 22 Ne, transfer the gas to the packaging system to get 8 x 800ml of 99% with a purity of 99.99% 22 Ne isotopic products.

Embodiment 3

[0039] Such as figure 1 shown, a 22 The recovery and utilization process of molecular sieve adsorption product gas in Ne separation, the process includes the recovery of molecular sieve adsorption product gas, the purification of recovered gas and other process steps; the flow chart of the recovery step of molecular sieve adsorption product gas is not shown, and the recovery The equipment of the gas purification step is the same as in Example 1.

[0040]Due to the cascade leakage of the tower, the impurity of the 9000ml initial product in the gas collecting bottle is too high, and the purity is 90%. In order to meet the purity requirements, the initial product is transferred into a purification bottle; it is purified with the same purification column in parallel with another bottle of secondary product with high impurities (purity 95%). The column is 800mm in length, 15mm in inner diameter, equipped with 500mm sponge body, and has 100mm of Cu chips on the upper and lower sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com