Method for improving transformation temperature of apical oxygen doping high temperature superconductor

A high-temperature superconductivity and transition temperature technology, which is applied in the usage of superconductor elements, superconducting devices, superconducting/high-conducting conductors, etc., and can solve the problem of non-adjustable oxygen content at the top angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Sr 2 CuO 3 Precursor preparation:

[0021] Using a solid-phase reaction method under normal pressure, 99.9% pure SrCO 3 Mix and grind CuO powder at a molar ratio of 2:1, sinter at 950-1000°C, keep it warm for 24 hours or repeat the sintering three times to obtain single-phase Sr 2 CuO 3 compound.

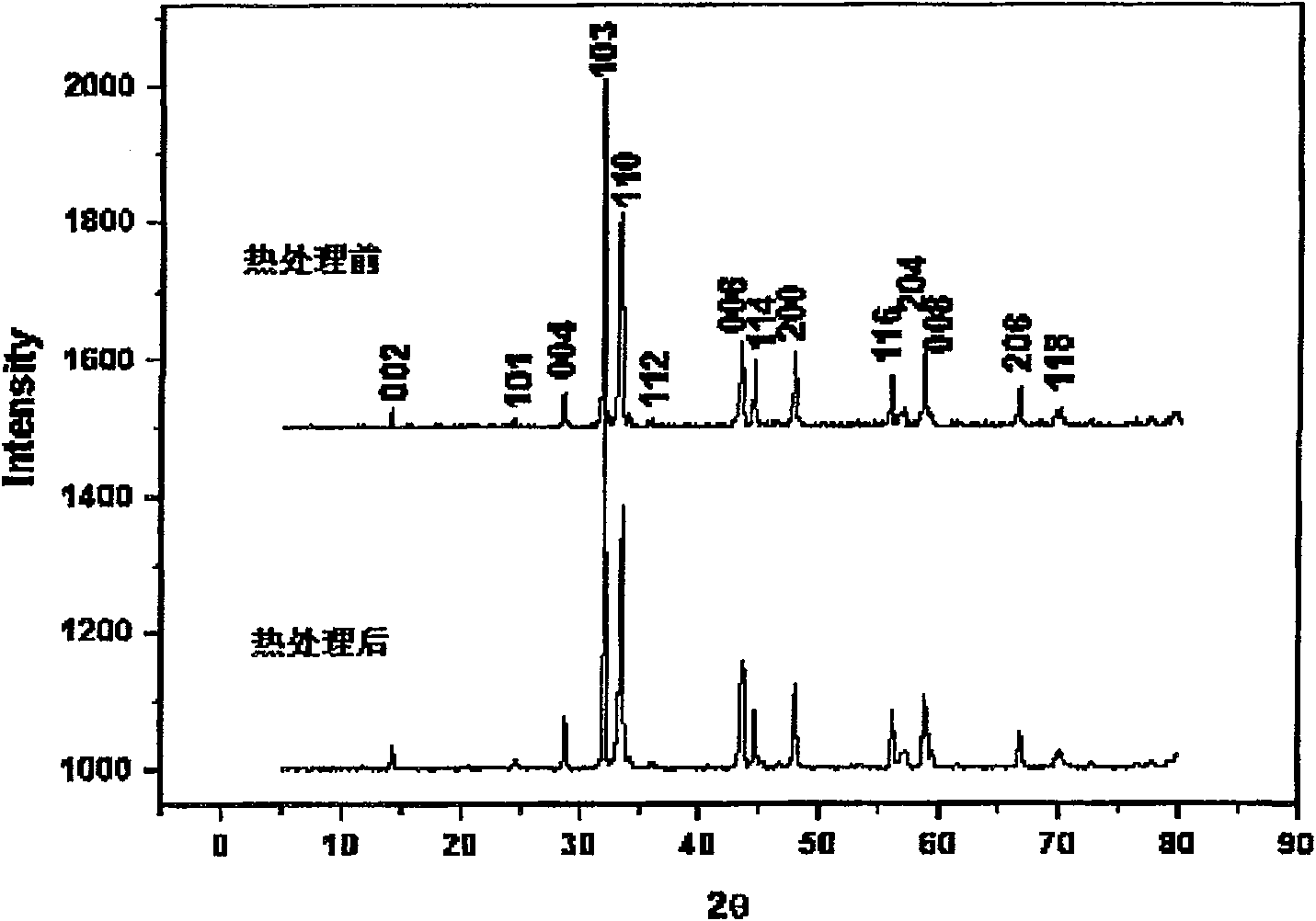

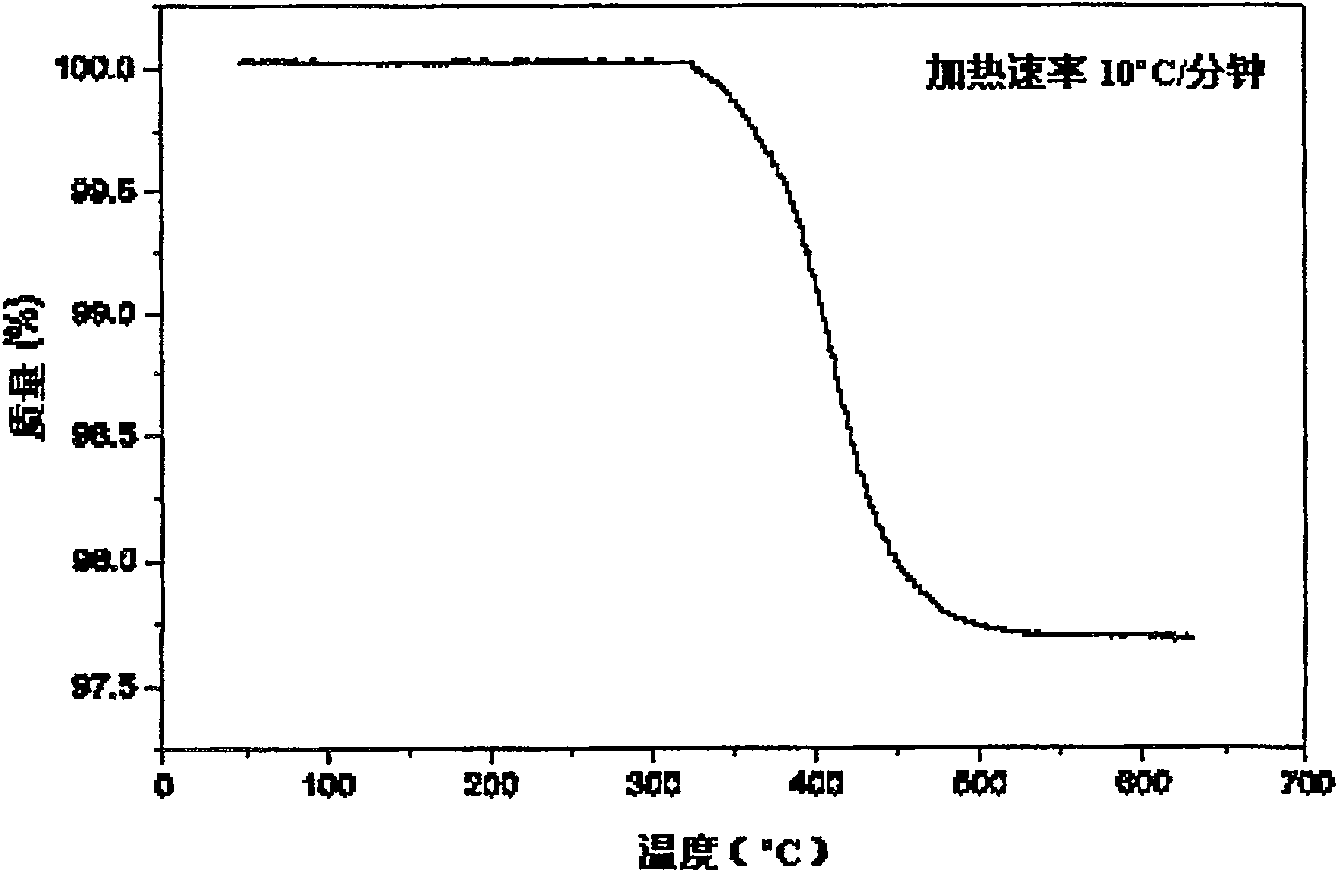

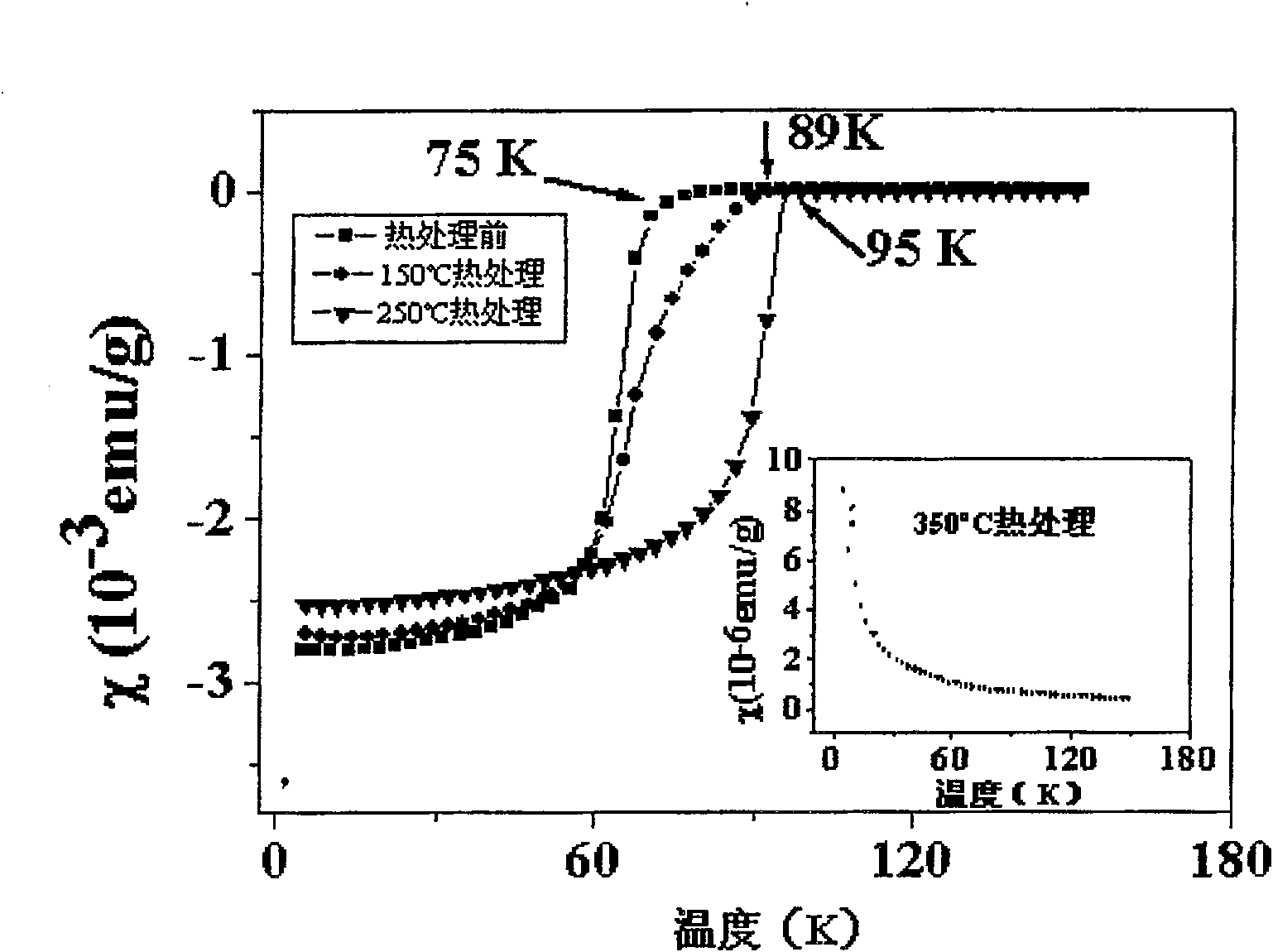

[0022] High pressure synthesis of Sr 2 CuO 3+δ superconductor

[0023] Using SrO 2 As an oxygen source, by controlling the oxygen content, high temperature and high pressure to prepare Sr 2 CuO 3+δ sample. The precursor Sr 2 CuO 3 , SrO 2 and CuO according to the molar ratio of (1-x):2x:x (x=0.1) were weighed, mixed and uniformly ground in a glove box filled with argon. Then pressed into a small disc with a diameter of 5 mm, wrapped with gold foil, and packaged in a Φ8×15 mm NaCl cylinder. Put the pressed sample into the graphite furnace and put it into the high-pressure assembly device for high-pressure synthesis. The sample synthesis is carried out on a larg...

Embodiment 2

[0027] Sr 2 CuO 3 Precursor preparation and high-pressure synthesis of Sr 2 CuO 3+δ The procedure of the superconductor is the same as that of Example 1; except that x=0.3, the pressure is 7GPa, and the temperature is 900°C.

[0028] High pressure synthesized Sr 2 CuO 3+δ Low temperature heat treatment of superconductors

[0029]In a tube furnace, under an inert gas atmosphere (such as Ar gas), the high-pressure synthesized Sr 2 CuO 3+δ The superconducting samples were heat-treated at 250 °C for 10 h.

Embodiment 3

[0031] Sr 2 CuO 3 Precursor preparation and high-pressure synthesis of Sr 2 CuO 3+δ The procedure of the superconductor is the same as in Example 1; except that x=0.7, the pressure is 5GPa, and the temperature is 1000°C.

[0032] High pressure synthesized Sr 2 CuO 3+δ Low temperature heat treatment of superconductors

[0033] In a tube furnace, under an inert gas atmosphere (such as N 2 ) the high pressure synthesized Sr 2 CuO 3+δ The superconducting samples were heat-treated at 300°C for 8 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com