Aerating unit for film component

An aeration device and membrane module technology, applied in the field of water treatment, can solve problems such as complex manufacturing process, affecting membrane cleaning effect, and reducing the service life of components, so as to improve the utilization rate of membrane filaments, avoid product defects, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

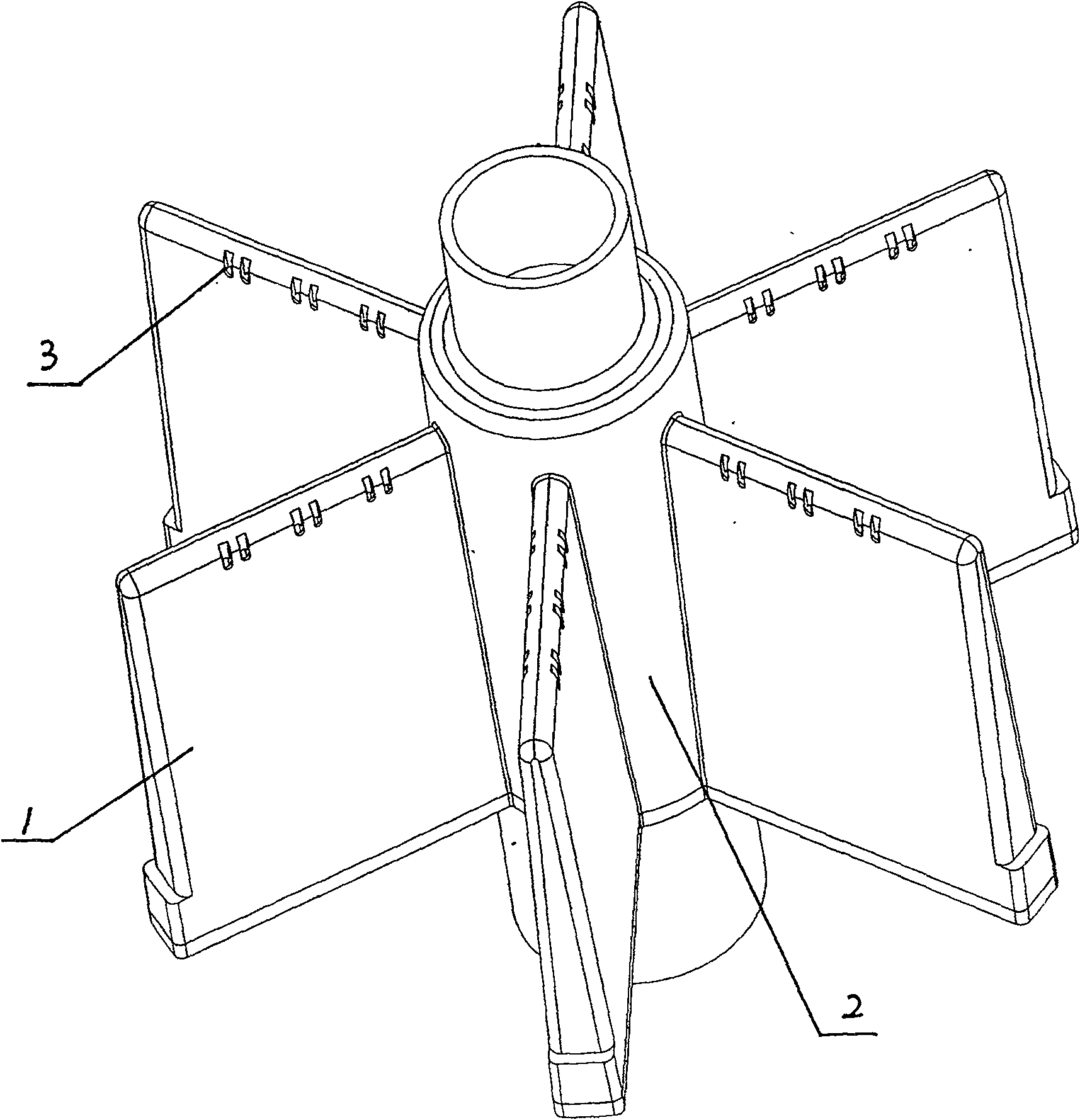

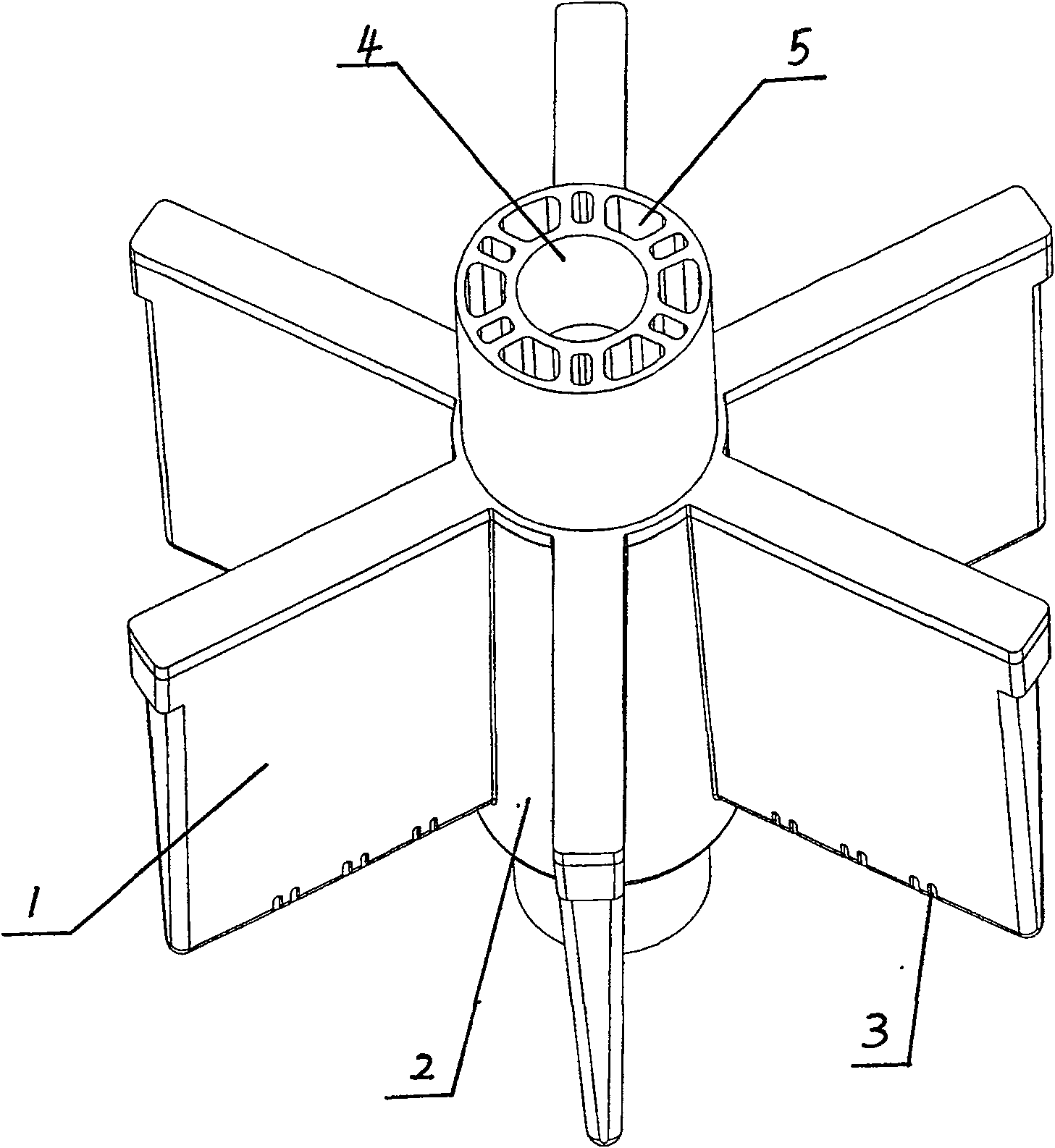

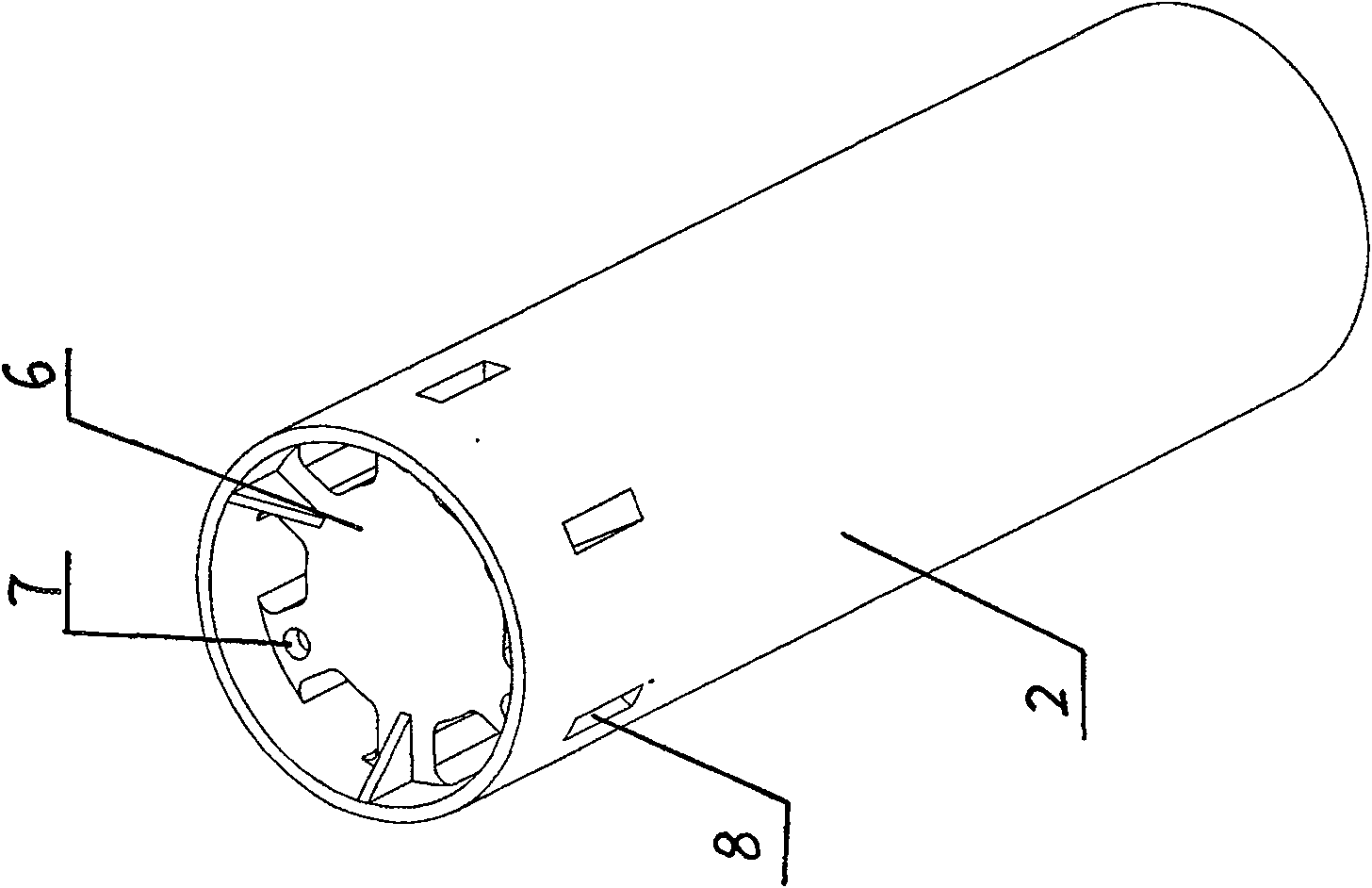

[0026] The schematic diagram of the aeration device of the present invention is as Figure 1-Figure 5 As shown, the aeration body 2 is included, the aeration body 2 is provided with an air collection chamber 4, and the outside of the aeration body 2 is connected with a plurality of closed air chambers 1 communicating with the air collection chamber through the air holes 8 on the aeration body , each air chamber is provided with a plurality of aeration holes 3 . The number of air chambers is generally 2-20 pieces, and the number of aeration holes can be selected between 1-1000. In order to simplify the manufacturing process, the aeration body can be a hollow cylindrical body, and the upper end of the hollow part is closed as an air collection chamber. The lower part of the gas collection chamber is sealed and connected with the aeration colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com