Nitrogen-enriched gas preparation method, gas separation method and nitrogen-enriched gas preparation device

A nitrogen and gas-enriched technology, applied in separation methods, specific gas purification/separation, nitrogen purification/separation, etc., can solve problems such as time-consuming, inability to give full play to compressor performance, and unsatisfactory power saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

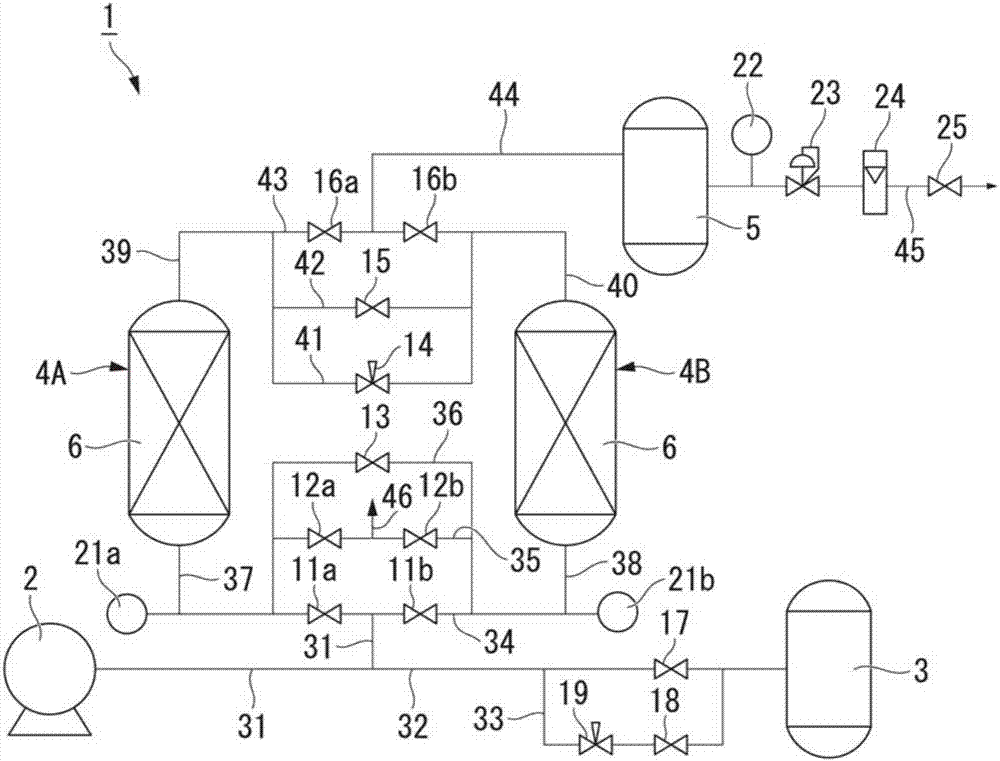

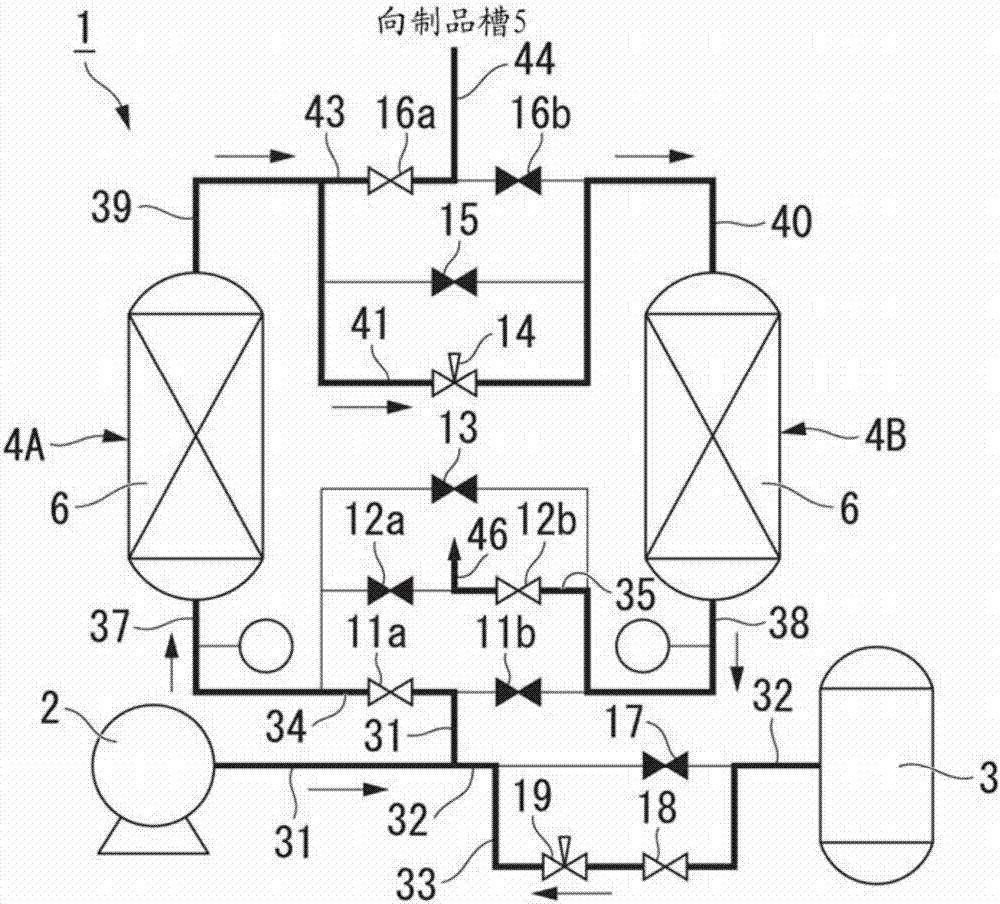

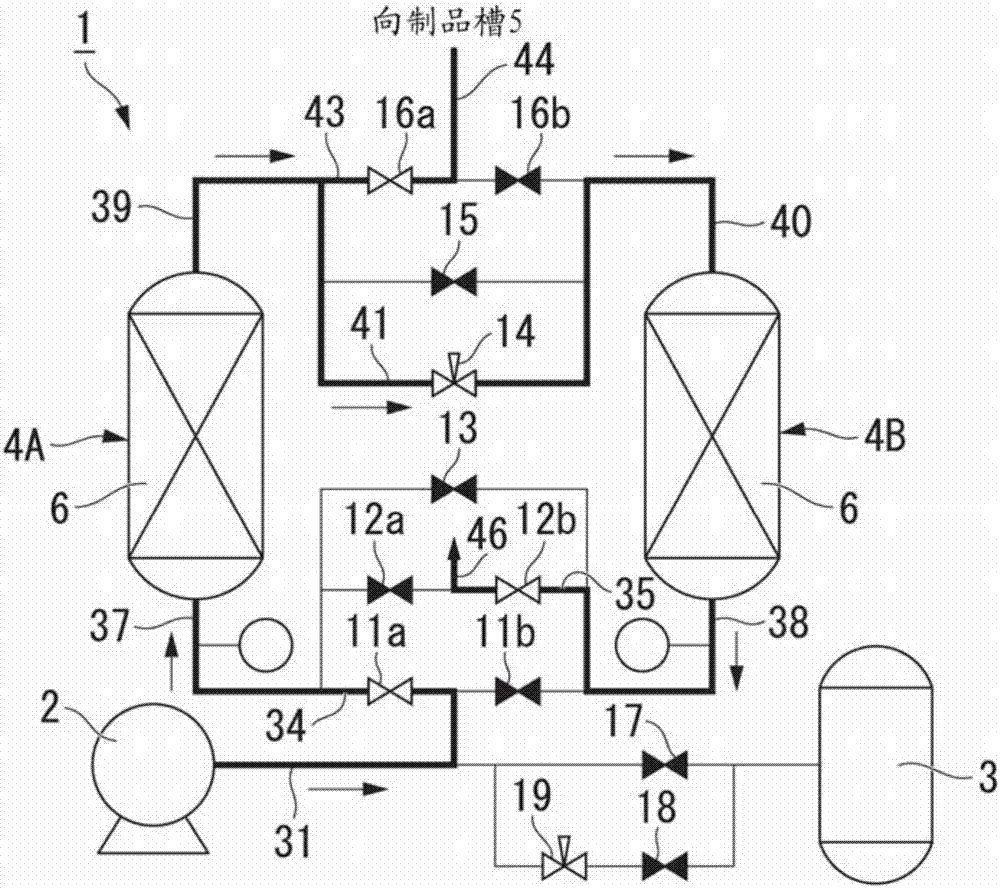

[0051] Next, the nitrogen-enriched gas preparation device and the nitrogen-enriched gas preparation method applicable to the present invention will be described in detail with reference to the accompanying drawings.

[0052]

[0053] The nitrogen-enriched gas preparation device 1 of the present embodiment is a preparation device in the PSA mode, such as figure 1 Shown is a structure including a raw material air compressor 2 , a compressed raw air tank 3 , two adsorption tanks (a first adsorption tank 4A and a second adsorption tank 4B ), and a product tank 5 .

[0054] Raw air compressor 2 is a device for compressing raw air, connected to the first adsorption tank 4A through the inlet valve 11a and through pipelines 31, 34, 37, and connected to the second adsorption tank 4B through the inlet valve 11b through pipelines 31, 34, 38 connect.

[0055] In addition, the first adsorption tank 4A and the second adsorption tank 4B are filled with an adsorbent 6 that preferentially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com