Method for producing hydrogen gas and methanol using solar energy

A technology for producing hydrogen and solar energy, which is applied in the field of solar energy utilization and chemical industry, can solve the problem of difficult storage of solar energy, and achieve the effect of obvious social value, huge economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: Utilize solar energy to produce hydrogen

[0044] First, the basic principle of hydrogen production: the reaction of decomposing water into hydrogen and oxygen cannot proceed spontaneously, but mainly through the following four processes to chemically convert water into a compound that is easy to be photolyzed, and decompose it with light Among them, the compounds that are difficult to pyrolyze complete a hydrogen production cycle, and finally realize the forward reaction.

[0045] 1) Manufacture of salt: 6I 2 +6Ca(OH) 2 =5CaI 2 +Ca(IO 3 ) 2 ↓+6H 2 o

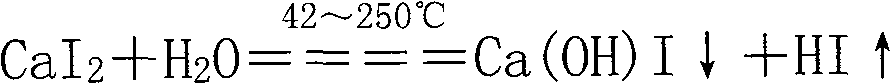

[0046] 2) Splitting of water:

[0047] 3) Release hydrogen:

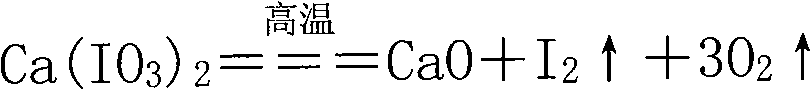

[0048] 4) Release oxygen:

[0049] Second. The main production process of hydrogen production:

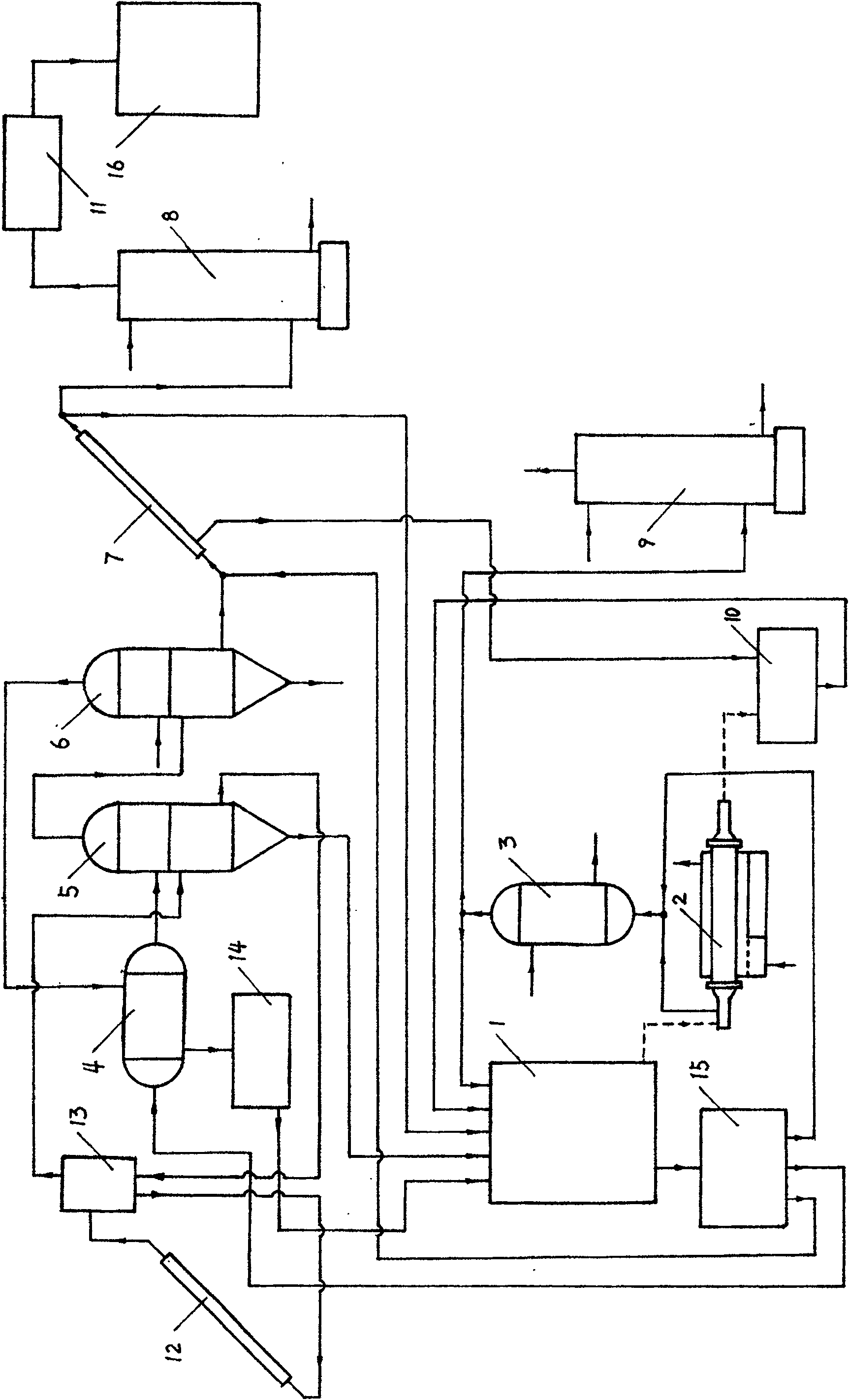

[0050] The main process of producing hydrogen includes: ① solar energy to produce water vapor; ② preparation and separation of salt; ③ moderate temperature hydrolysis of calcium iodide solution and preparation of hydroiodic acid; ④ prep...

Embodiment 2

[0119] The photolysis device that utilizes solar energy to produce hydrogen or methanol, i.e. the photolysis pool (7), is integrated with the solar heat collector (12), i.e. the photolysis pool (7) is on the top, and the heat collector (12) is on the bottom. The bottom plate of the photolysis pool (7) is light-transmitting glass, which is parallel to the light-transmitting glass on the upper panel of the heat collector (12) and has a thermal insulation interval. The two are combined to make the sunlight that cannot be photolyzed enter the absorber of the heat collector (12) and become heat energy, thereby improving the utilization rate.

Embodiment 3

[0121]In the method of utilizing solar energy to produce hydrogen or methanol, the water vapor produced by the solar heat collector (12) is first input into the steam turbine generator set to generate electricity, and then enters the evaporator I (5). The electric energy produced by the generating set passes through the electric furnace to provide heat for the calciner (2) to calcinate the calcium iodate. Moreover, when there is no sunlight, the electric light source composed of high-brightness light-emitting diodes is powered to maintain the photolysis reaction, so that the whole process continues uninterrupted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com