Flame proof systematization design method based on monolithic heavy sectional steel structure

A design method and steel structure technology, applied in fire protection, calculation, building components, etc., can solve problems such as failure to realize the coupling of fire simulation and structural analysis, failure to consider the interaction of components, and being too conservative

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

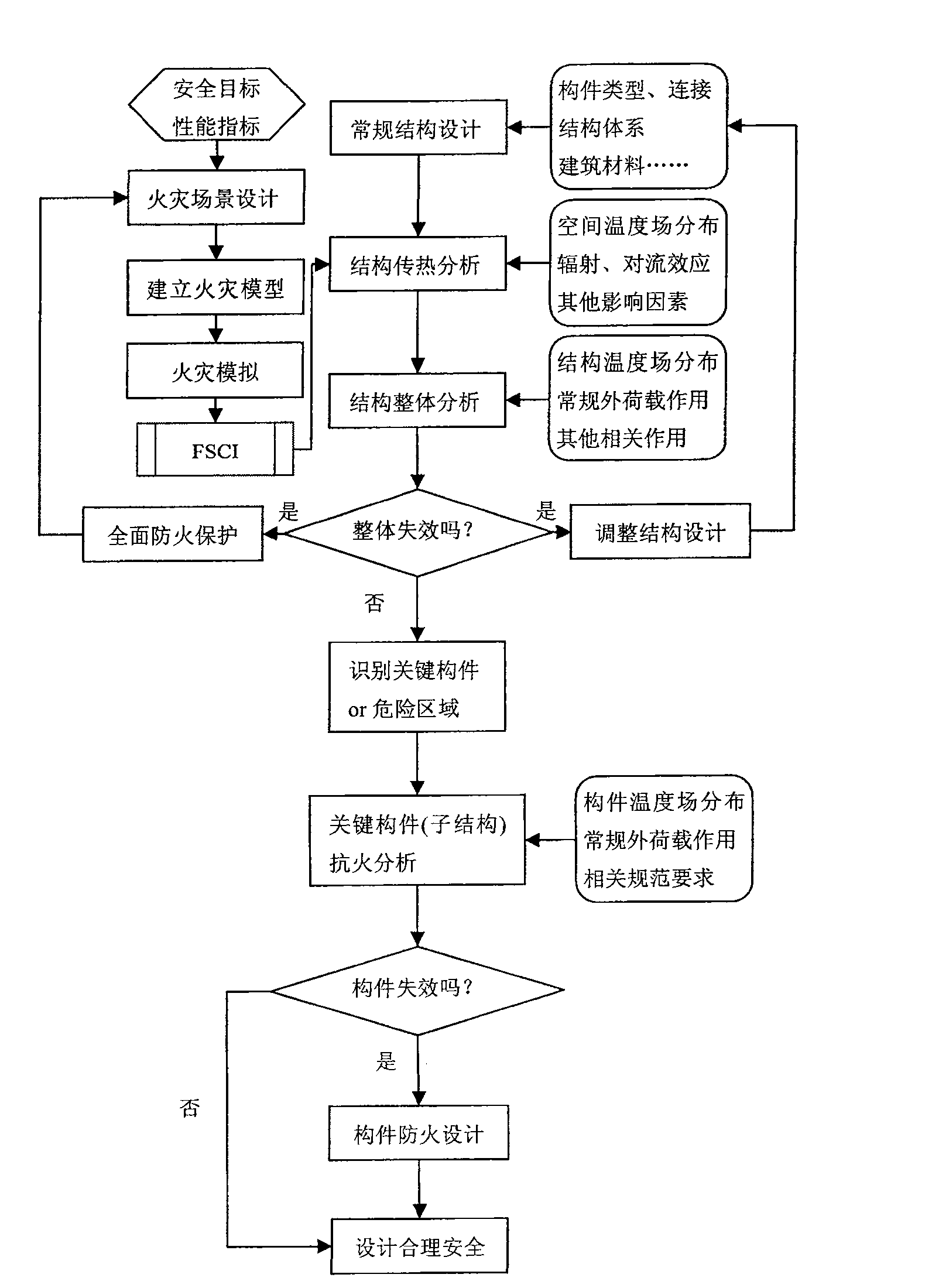

Method used

Image

Examples

Embodiment Construction

[0079] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

[0080] 1. Problem description

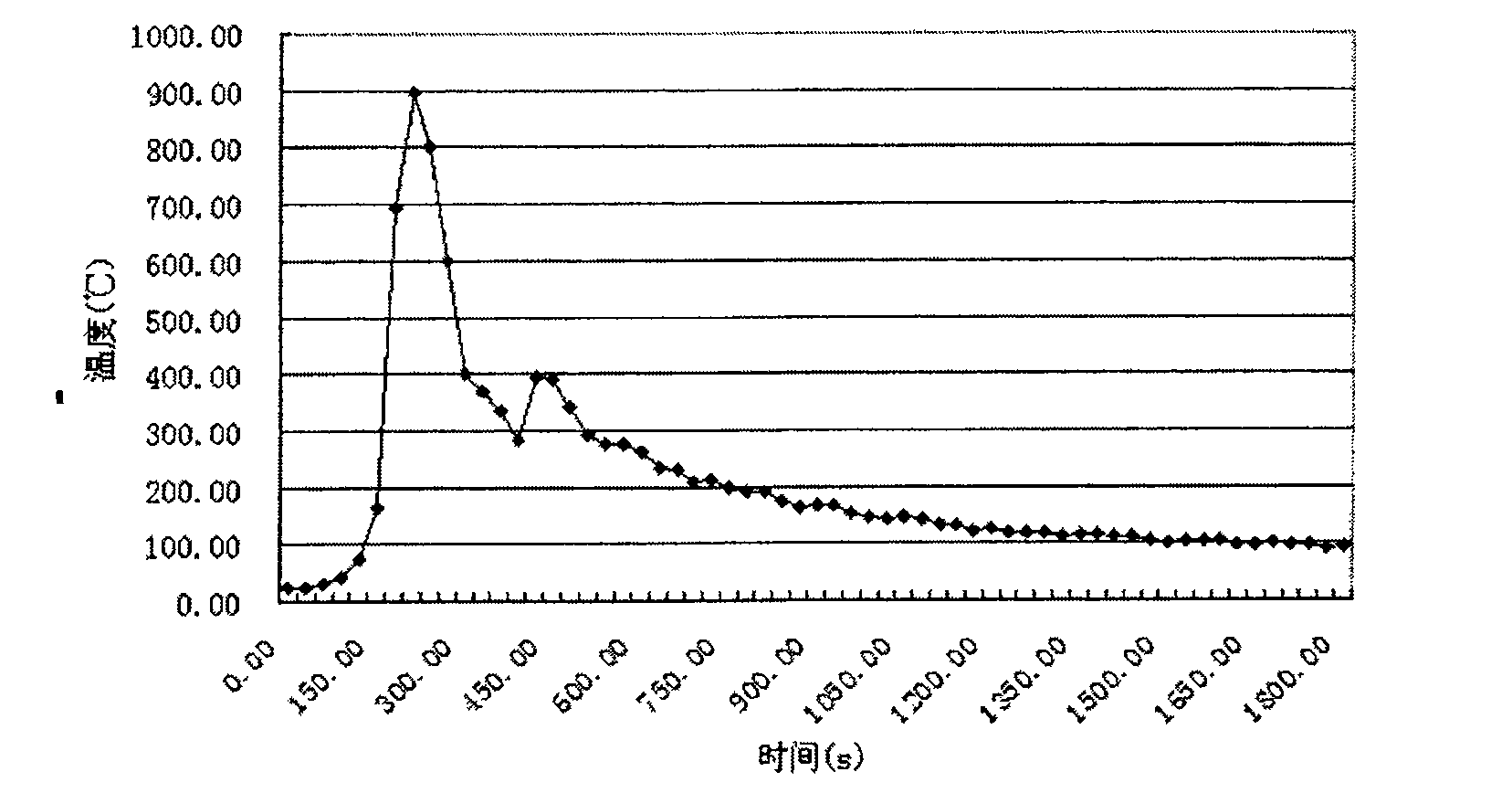

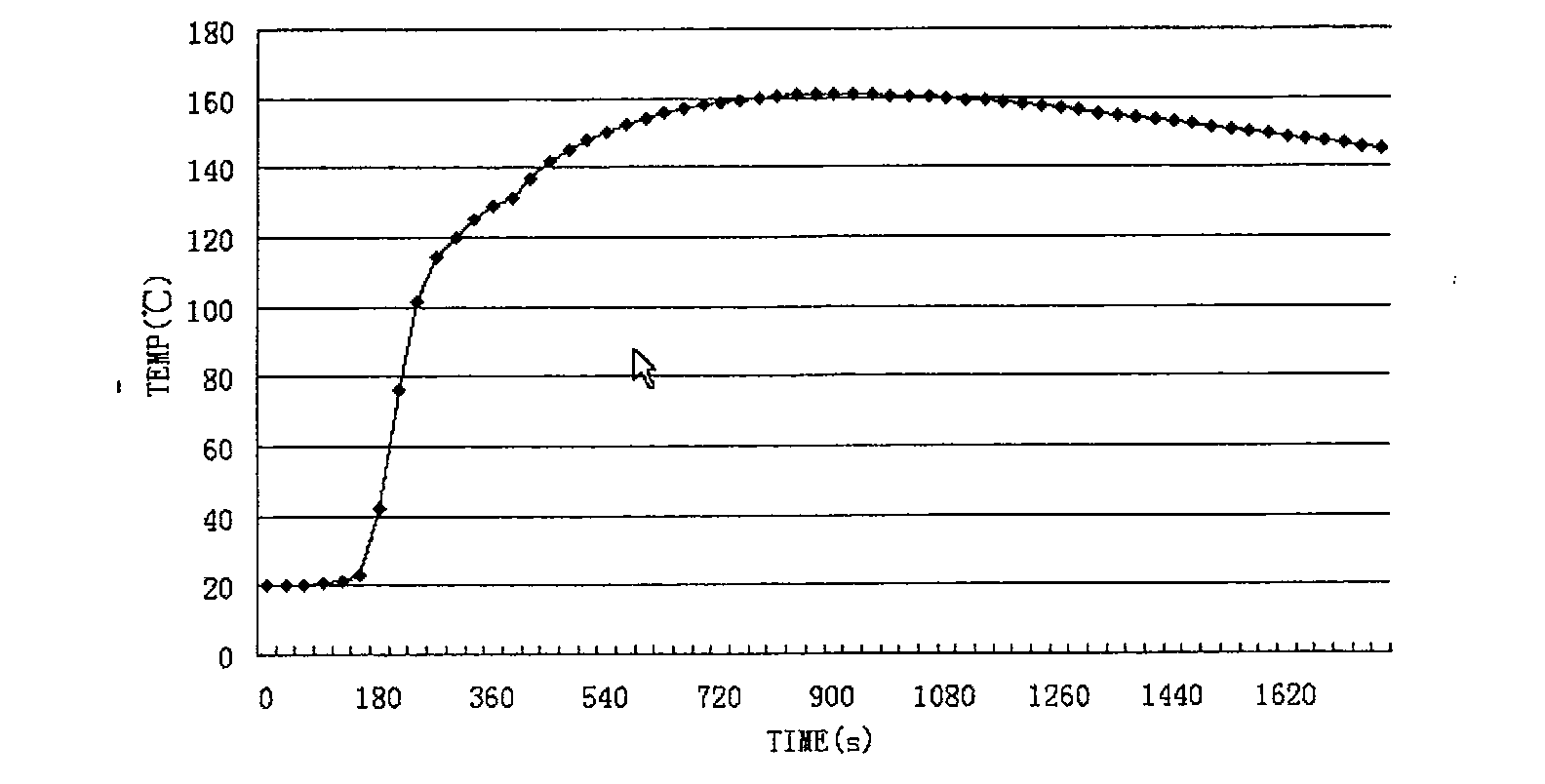

[0081] The project applied in this embodiment is the panorama gallery of radio and television transmission towers in XX province. The TV tower has a construction height of 388 meters and is divided into four parts: tower base, tower body, tower and mast. The tower base includes 1 floor underground, 4 floors above the ground and the roof; Steel structure, the type of steel is Q345.

[0082] The Panorama Gallery is a very distinctive indoor exhibition hall in the building, distributed on the third and fourth floors of the tower, and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com