Method for preparing barium stan-titanate ferroelectric film

A ferroelectric thin film, tetra-n-butyl titanate technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, devices for coating liquid on the surface, special surfaces, etc., can solve the problems of unfavorable mass production and high price problems, to achieve the effect of easy purchase, good performance, and reduced leakage conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

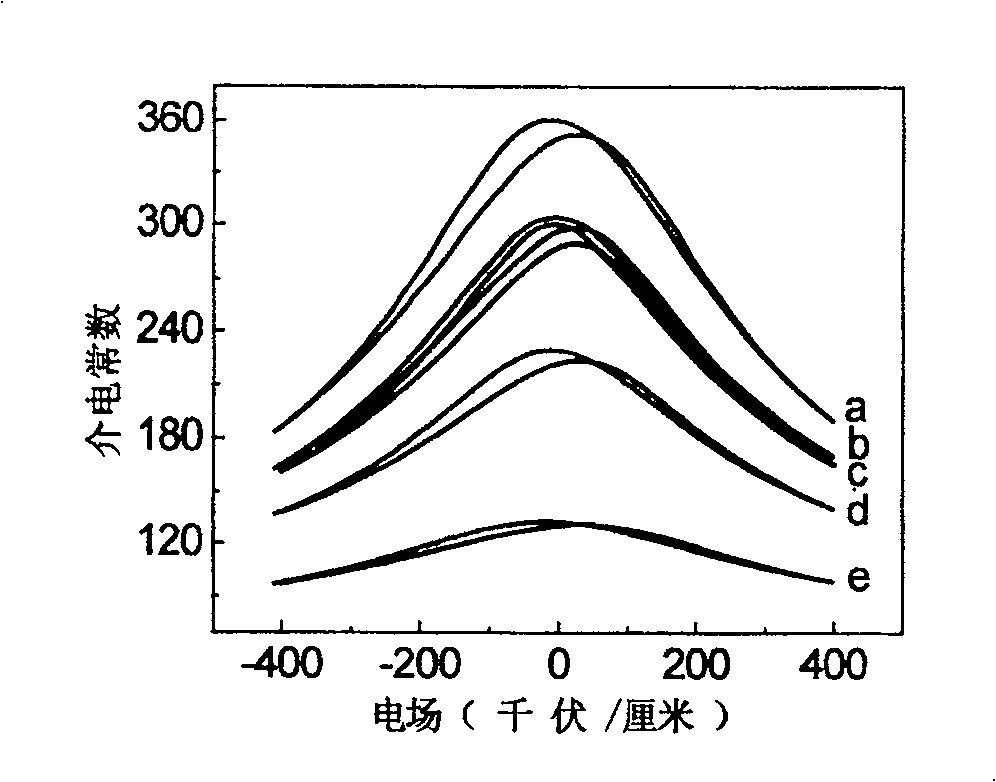

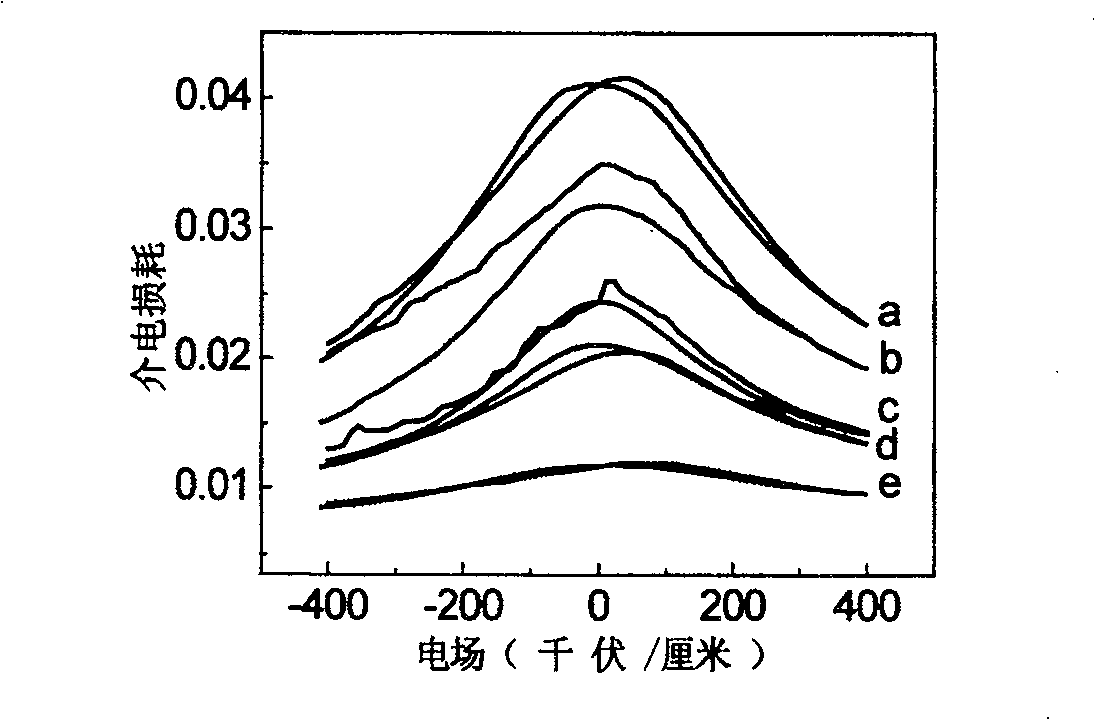

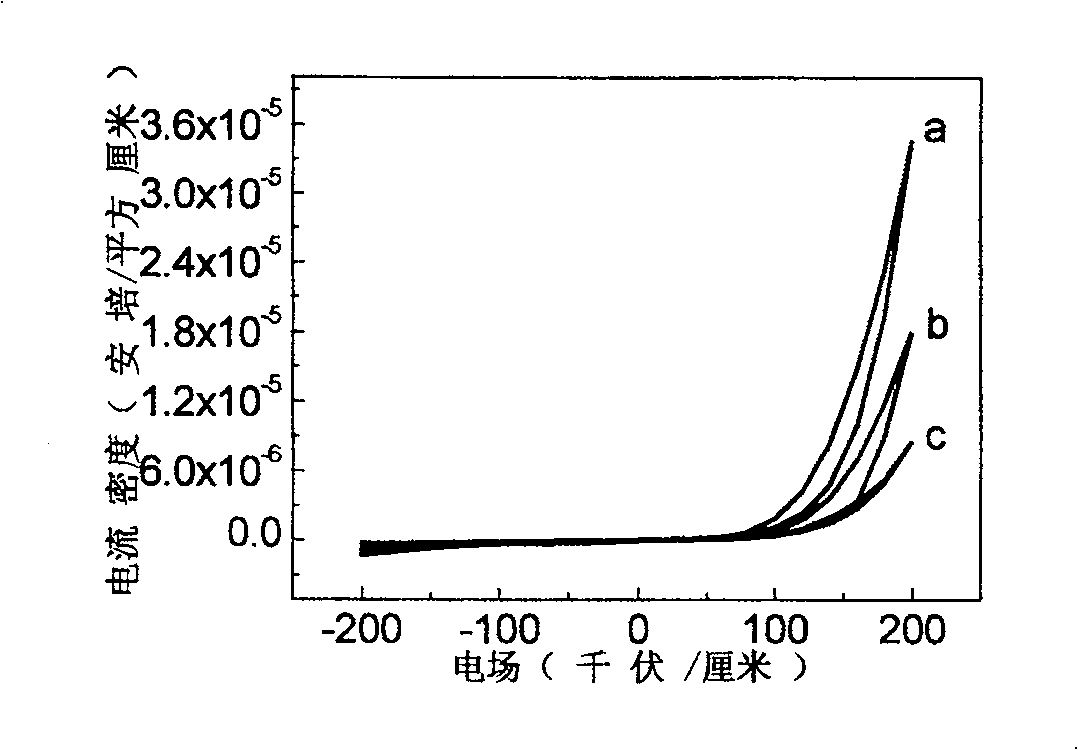

[0018] Preparation of barium tin titanate Ba(Ti 1-x Sn x )O 3 , X=0.05, 0.1, 0.15, 0.2 and 0.25 ferroelectric thin film.

[0019] The chemical raw material used is barium acetate [Ba(CH 3 COO) 2 ], dibutyltin oxide [(C 4 H 9 ) 2 SnO, purity 98%] and tetra-n-butyl titanate [Ti(OC 4 H 9 ) 4 ], the solvent is glacial acetic acid and ethyl glycol ether. First heat barium acetate and dibutyltin oxide (according to a certain stoichiometric ratio x = 0.05, 0.10, 0.15, 0.2 and 0.25) in glacial acetic acid solution to boiling, stop heating after 10 minutes, and cool to room temperature, Ba The molar ratio of +Sn to glacial acetic acid is 1:10. Then add the mixed solution of tetra-n-butyl titanate, ethyl glycol ether and acetylacetone (AcAc) into the glacial acetic acid solution containing barium and tin, where the molar ratio of Ti to AcAc is 1:2, The molar ratio of n-butyl ester to ethylene glycol ether is 1:10. Finally, glacial acetic acid was added to adjust the concentration of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com