Organic/inorganic composite porous film and electrochemical device prepared thereby

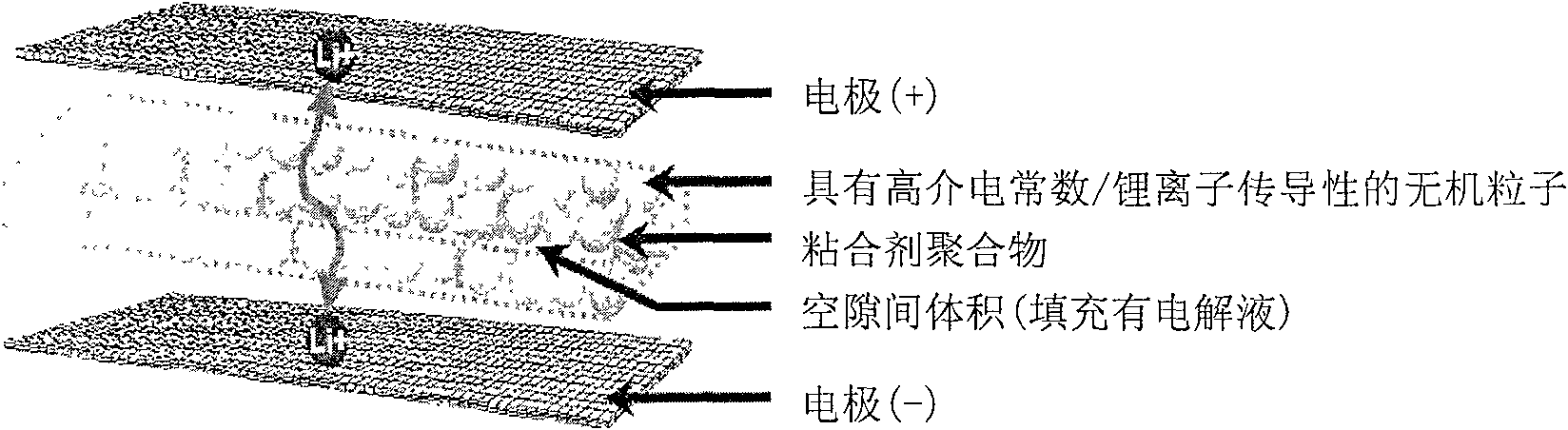

An inorganic composite and porous film technology, which is applied in circuits, electrical components, lithium batteries, etc., can solve the problems of battery performance degradation and insufficient electrolyte, so as to improve battery performance, improve lithium ion conductivity and heat resistance, and reduce The effect of interfacial resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

[0090] Preparation of Organic / Inorganic Composite Porous Thin Film and Its Use to Fabricate Lithium Secondary Batteries

Embodiment 1

[0092] 1-1. Organic / inorganic composite porous film (PVdF-HFP / BaTiO 3 ) preparation

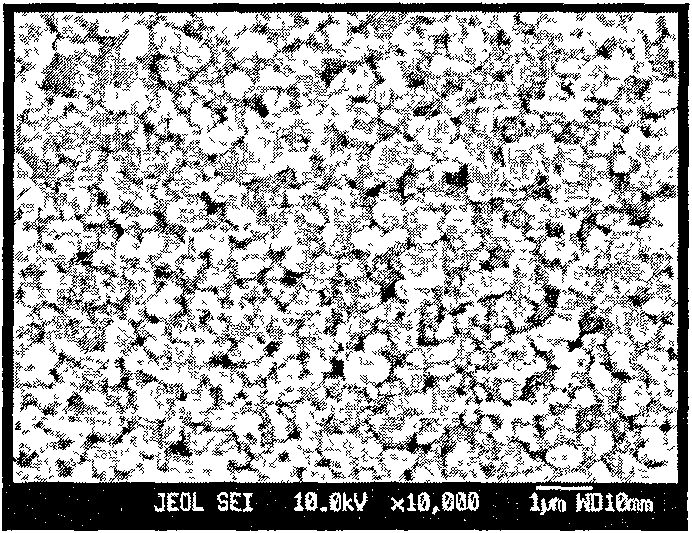

[0093] A PVdF-HFP polymer (polyvinylidene fluoride-hexafluoropropylene copolymer) was added in an amount of about 5 wt % to tetrahydrofuran (THF), and dissolved therein at 50° C. for about 12 hours or more to form a polymer solution. To the polymer solution obtained as described above, BaTiO with a particle diameter of about 400 nm was added at a concentration of 20% by weight based on the total solids content. 3 powder, and then dispersed to form a mixed solution (BaTiO 3 / PVdF-HFP=80:20 (weight ratio)). Then, the mixed solution obtained as described above was coated on a Teflon sheet by using a doctor blade coating method. After coating, dry THF, and separate the Teflon sheet to obtain the final organic / inorganic composite porous film (see figure 1 ). The final film has a thickness of about 30 μm. The final organic / inorganic composite porous film had a pore size of 0.4 μm and a ...

Embodiment 2

[0102] Repeat embodiment 1 to obtain lithium secondary battery, except using BaTiO 3 and Al 2 o 3 (weight ratio = 20:80) mixed powder instead of BaTiO 3 powder to obtain organic / inorganic composite porous film (PVdF-HFP / BaTiO 3 -Al 2 o 3 ). The final organic / inorganic composite porous film had a thickness of 25 μm, a pore size of 0.3 μm, and a porosity of 57% after measurement with a porosimeter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com