Acrylate emulsifying thickening agent and production process thereof

An emulsifying thickener and acrylate technology, which is applied in the field of pigment printing thickener, can solve the problems of fabric hand feeling, unsatisfactory color yield, poor fabric outline definition, poor electrolyte resistance, etc., and achieve printing effect Good, clear outline, and improved water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

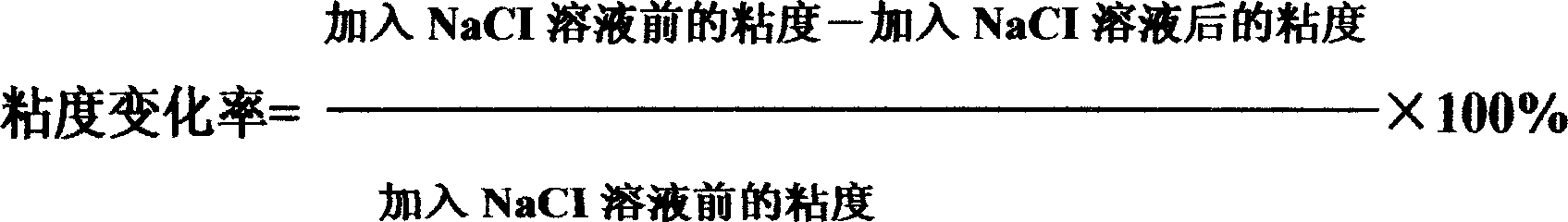

Image

Examples

Embodiment Construction

[0021] (1) Neutralize 160 grams of acrylic acid with 310 grams of 20% ammonia water to pH=6.5-7.5;

[0022] (2) Add 90 grams of vinylbenzene sulfonic acid, 18 grams of 2-acrylamido-2-methylpropanesulfonic acid, 23 grams of trimethylaminopropyl methacrylamide chloride, and crosslinking agent dimethacrylic acid Mix 3 grams of glycerides to form an aqueous phase;

[0023] (3) Add 120 grams of organic solvent No. 200 mineral spirits to the reaction kettle, add 20 grams of emulsifier sorbitan monooleate under stirring, and slowly add the water phase to emulsify 30 -35 minutes, after full emulsification, add dropwise a mixture of 6 grams of initiator ammonium persulfate and 70 grams of deionized water, polymerize at 60-70℃ for 3.5-4 hours, add emulsifier hydrogenated castor oil polyoxyethylene ether 5 Grams, add 20 grams of solvent No. 200 solvent naphtha with stirring, after fully emulsified,

[0024] (4) Add 4 grams of modified silicone linear body to obtain acrylate emulsified thicke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com