Optical component for optical communication

A technology of optical components and optical communication, applied in the direction of optical components, optics, light guides, etc., can solve the problems of discarding optical components, increasing the number of problems, deviation of optical characteristics, etc., achieve high-precision optical characteristics, improve degrees of freedom, and reduce size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

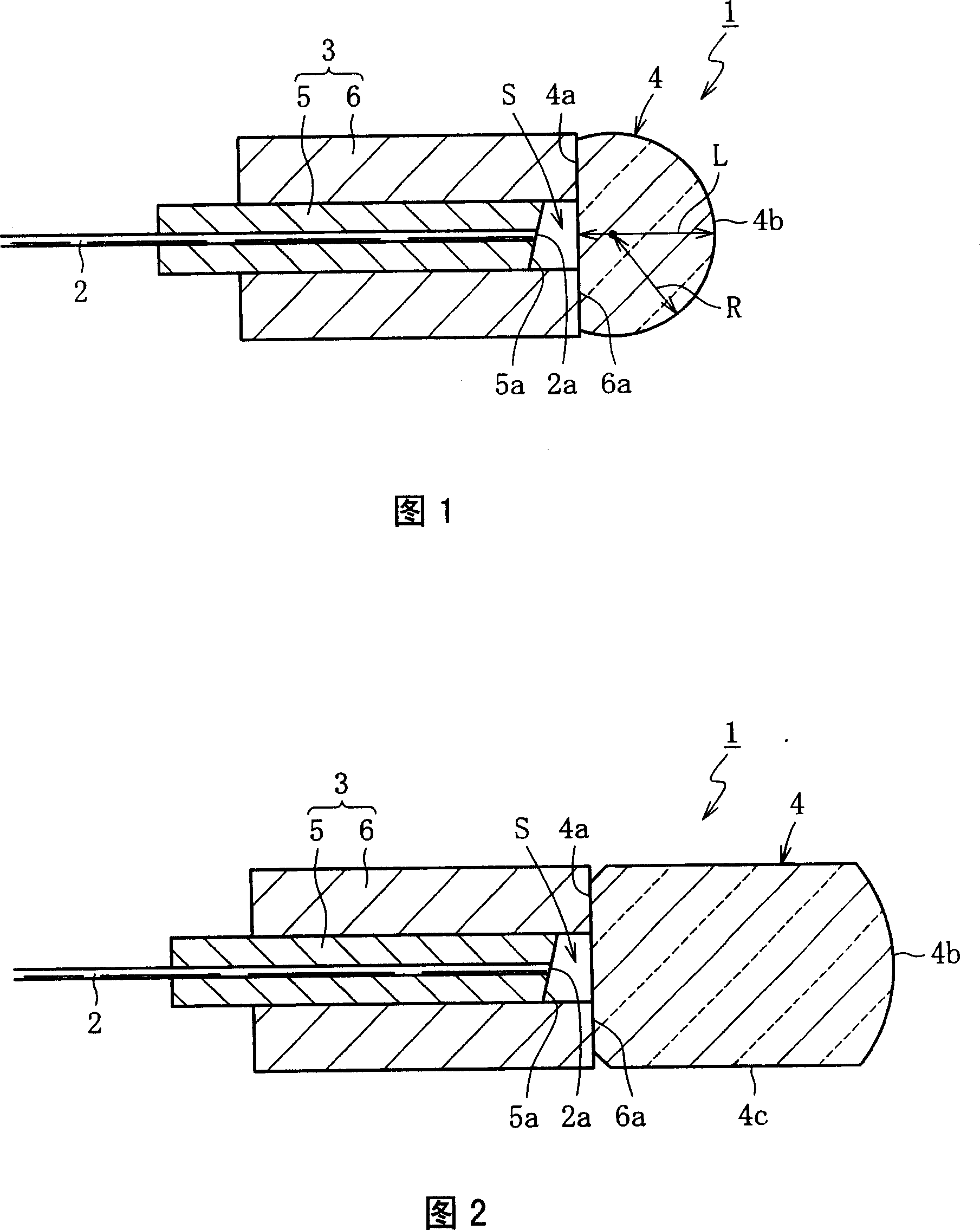

[0057] In Example 1 of the present invention, an optical collimator 1 having the structure shown in FIG. 1 (first embodiment) was manufactured. In the light collimator 1 according to Example 1, the first holding member 5 is made of glass, has an outer diameter of 0.25 mm, an inner diameter of 0.126 mm, and a total length of 3 mm. The end face of the first holding member 5 was ground so that the end face was inclined at an inclination angle of 8 degrees with respect to the normal to the optical axis, thereby forming an inclined surface 5 a. The optical fiber 2 is held in the inner hole of the first holding member 5, wherein the end face of the optical fiber 2 is ground together with the end face of the first holding member 5 (before the inclined surface 5a is formed). The second holding member 6 of the optical collimator 1 is made of glass, has an outer diameter of 1 mm, an inner diameter of 0.255 mm, and a total length of 2 mm. The second holding member 6 is fitted to the out...

example 2

[0063] In Example 2 of the present invention, an optical collimator 1 having the structure shown in FIG. 2 (second embodiment) was fabricated. In light collimator 1 according to Example 2, for example, in each of first holding member 5 and second holding member 6 , the size and material of each part are the same as in Example 1 described above. The lens 4 of the light collimator 1 is formed with a spherical lens as an initial lens, which has a diameter of 2 mm and is made of optical glass RH-21 (manufactured by Nippon Electric Glass Co., Ltd.) having a substantially uniform refractive index. . A part of the spherical lens is subjected to grinding processing or the like so that the distance between the end vertices of the flat surface portion 4 a and the spherical surface portion 4 b becomes 1.8 mm. The bonding state between the second holding member 6 and the lens 4 and the fact that the antireflection coating is formed in place are the same as in Example 1 above. In order t...

example 3

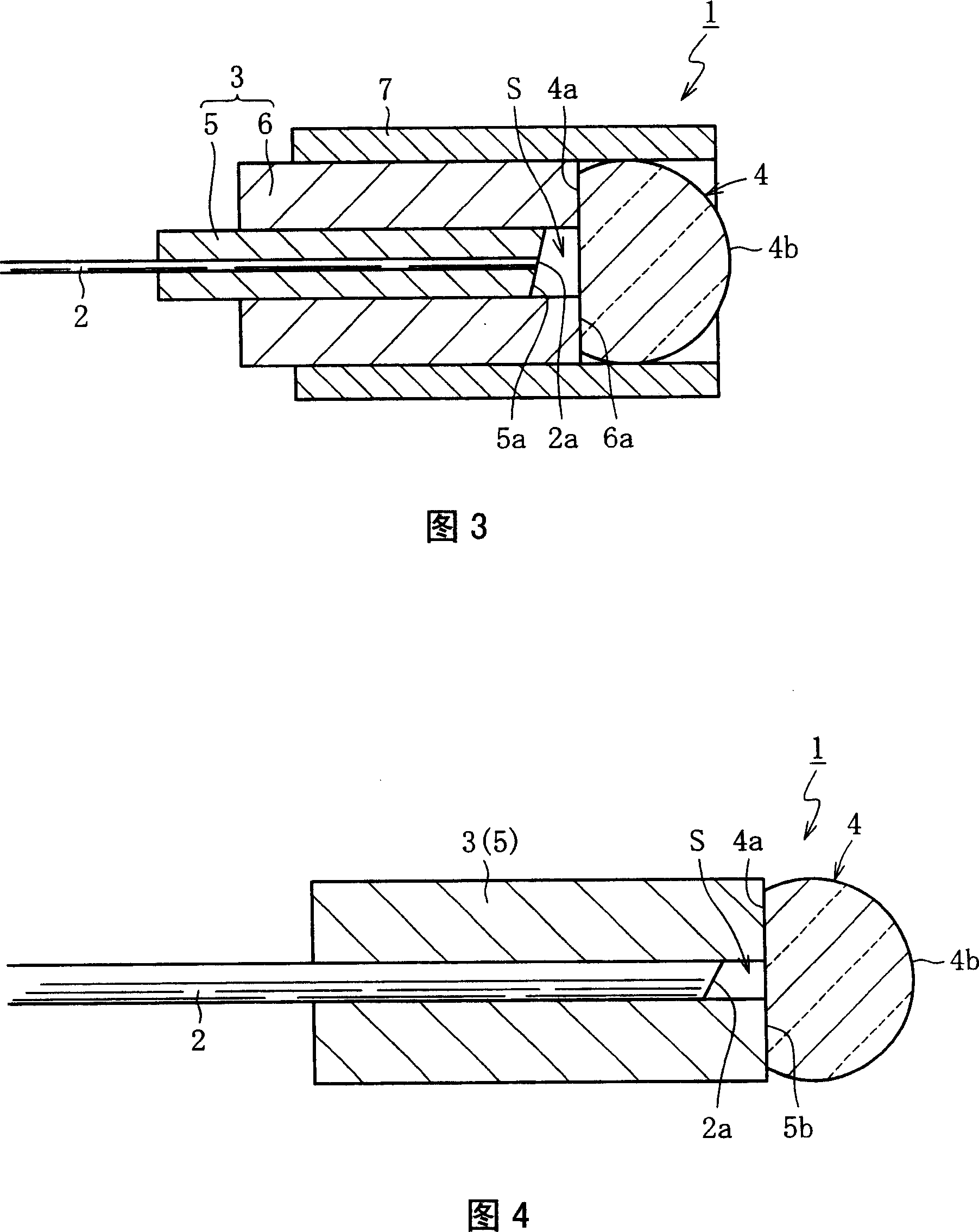

[0069] In Example 3 of the present invention, an optical collimator 1 having a structure as shown in FIG. 3 (third embodiment) was manufactured. In light collimator 1 according to Example 3, for example, in each of first holding member 5 and second holding member 6 , the size and material of each part are the same as those in Example 1 or 2 described above. The lens 4 of the light collimator 1 is formed with a spherical lens as an initial lens, which has a diameter of 1 mm and is made of optical glass RH-21 (manufactured by Nippon Electric Glass Co., Ltd.) having a substantially uniform refractive index. . A part of the spherical lens is subjected to grinding processing or the like so that the distance between the end vertices of the planar portion 4 a and the spherical portion 4 b becomes 0.7 mm. The outer sleeve 7 of the optical collimator 1 is made of glass, with an outer diameter of 1.4 mm, an inner diameter of 1 mm, and a total length of 3 mm. While the flat portion 6a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com