Preparation method of platinum nanoparticle electrocatalyst based on metal cluster approach

A technology of electrocatalysts and clusters, applied in the field of preparing platinum nano-electrocatalysts, which can solve problems such as catalyst poisoning, high polarization overpotential, and limited commercial development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

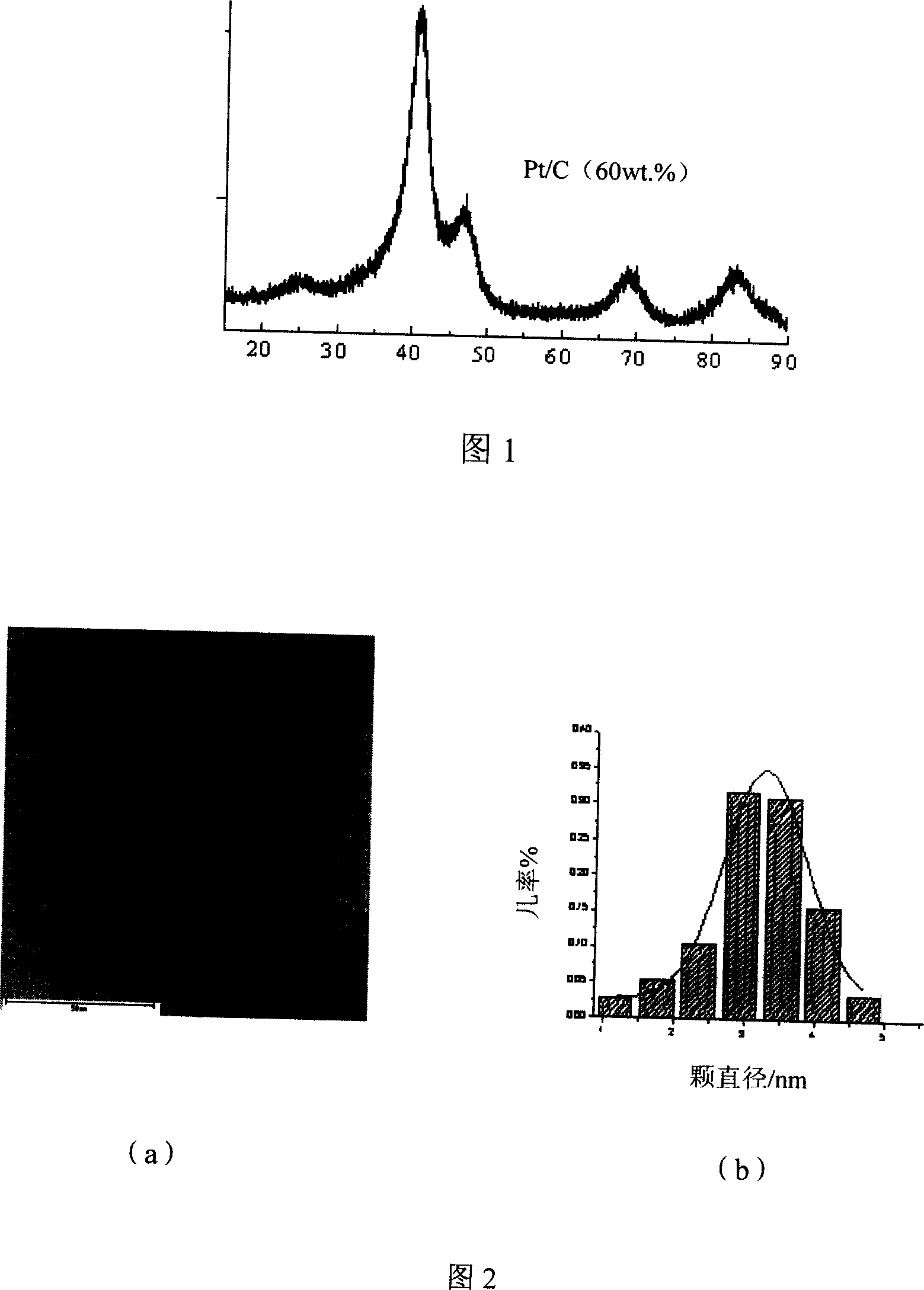

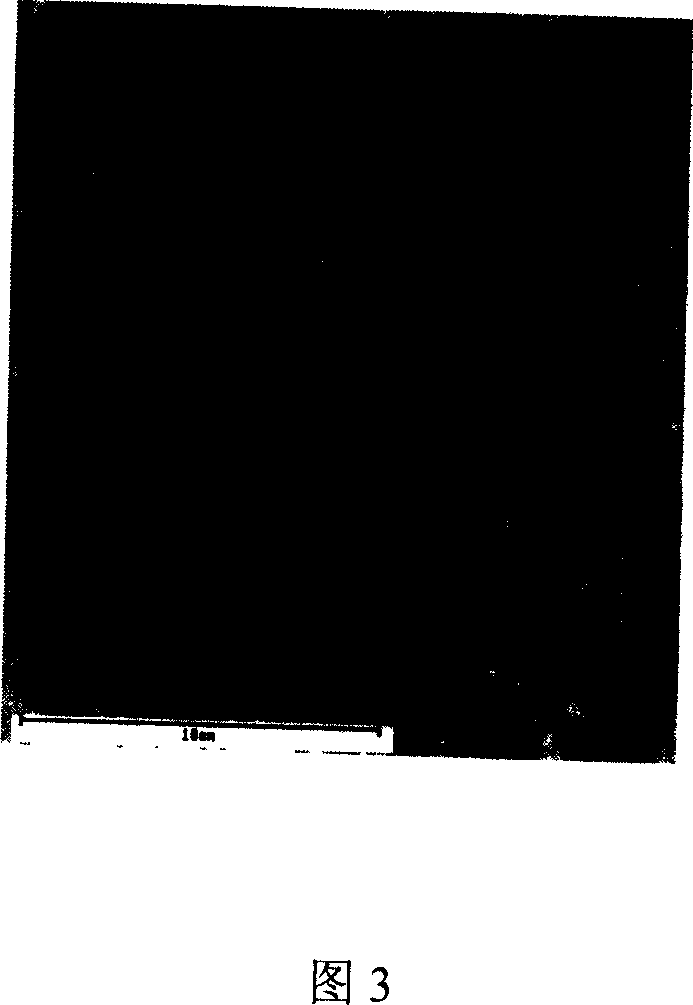

[0013] Example 1, the preparation of carbon-supported Pt (60wt.%) / C catalyst

[0014] 1. Weigh 159.7mg of Na 2 PtCl 6 6H 2 The anhydrous sodium acetate of O (metal platinum content 31.3%) and 170.0mg joins in the methyl alcohol of 30ml, Na 2 PtCl 6 6H 2 The concentration of O was 5.3 mg / ml. First pass high-purity nitrogen gas for 15 minutes to remove the air in the solution, then react in a CO atmosphere at 50°C for 20 minutes, and then react at room temperature and in a CO atmosphere for 24 hours to obtain a blue-green platinum cluster solution (group point A).

[0015] 2. Add 33.3 mg of Vulcan XC-72R activated carbon to the obtained component A under nitrogen protection, stir for 6 hours, evaporate methanol to dryness in a nitrogen atmosphere at 60°C, and cool to room temperature (component B).

[0016] 3. The component (B) is filtered, washed repeatedly, and tested with silver nitrate until there is no chloride ion, and then dried in nitrogen at 110° C. to obtain the...

example 2

[0018] The preparation of the nano-platinum catalyst of example 2 unsupported

[0019] 1. Weigh 159.7mg of Na 2 PtCl 6 6H 2 The anhydrous sodium acetate of O (metal platinum content 31.3%) and 170.0mg joins in the methyl alcohol of 30ml, Na 2 PtCl 6 6H 2 The concentration of O was 5.3 mg / ml. First pass high-purity nitrogen gas for 15 minutes to remove the air in the solution, then react in a CO atmosphere at 50°C for 60 minutes, and then react in a CO atmosphere at room temperature for 24 hours to obtain a blue-green platinum cluster solution (component A).

[0020] 2. Add 20 ml of a pre-prepared aqueous solution containing 3% sodium dodecylbenzenesulfonate to the obtained solution under the protection of nitrogen, stir continuously for 6 hours, and then cool to room temperature (component B).

[0021] 3. The component (B) is filtered, washed repeatedly, and tested with silver nitrate until there is no chloride ion, and then dried in nitrogen at 110° C. to obtain the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com