Enzyme method for hydrolyzing casein and synchronous preparation of phosphopeptide and non-phosphopeptide

A casein phosphopeptide, hydrolyzed casein technology, applied in protein food processing, protein food ingredients, food science and other directions, can solve the problems of functional component structure elucidation, complex process route, many types of enzymes, etc. Conducive to popularization and utilization, clear structure, and the effect of reducing ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

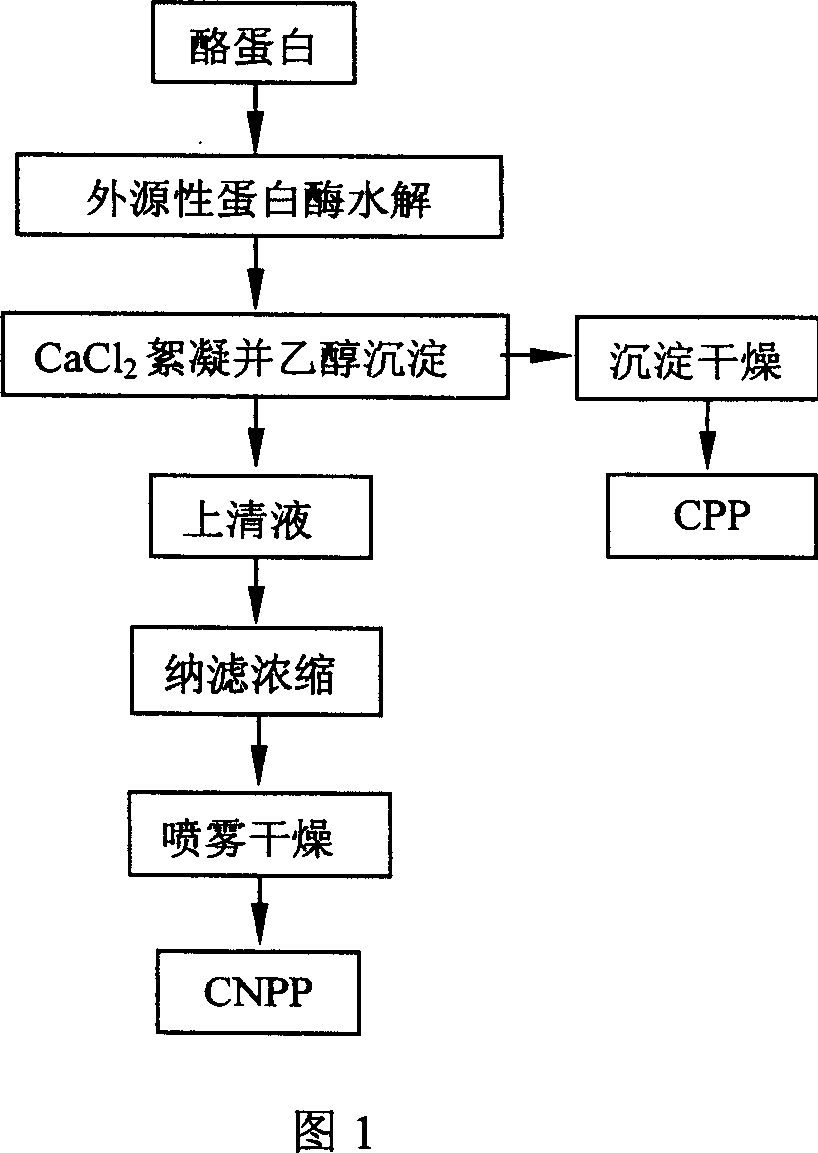

Embodiment 1

[0024] Enzyme reactions were performed in a 10 L sandwich reactor. Add 5000ml of water into the reactor, raise the temperature to 55°C, then weigh 1000g of casein, and slowly add it into the water while stirring. Adjust the pH value to 8.0 with 2mol / L NaOH, dissolve all the casein at 55°C, add 11.5mL Alcalase 2.4L, and monitor DH with TNBS. Add 60g anhydrous CaCl 2 , stirred until completely dissolved, then slowly added edible ethanol under stirring until the final concentration reached 70% (v / v), left for 30min, centrifuged (3000rpm, 20min), and the precipitate was vacuum-dried (40°C) to obtain 354g of CPP product . The supernatant enters the nanofiltration device (the relative molecular mass cut off by the nanofiltration membrane is 300D) to concentrate, and the permeate is used to recover ethanol, and the concentrated (concentration is 60mg / ml) liquid is put on a DA201-C macroporous adsorption resin chromatographic column, washed with water After desalting, use 70% ethan...

Embodiment 2

[0027] Enzyme reactions were performed in a 25L sandwich reactor. Add 15000ml of water into the reactor, raise the temperature to 65°C, then weigh 3750g of casein, and slowly add it into the water while stirring. Adjust the pH value to 8.5 with 2mol / L NaOH, dissolve all the casein at 65°C, add 2.4L of 55mL Alcalase, and monitor DH with TNBS. Add 180g anhydrous CaCl 2, stirred until completely dissolved, then slowly added edible ethanol under stirring until the final concentration reached 80% (v / v), left it overnight, centrifuged (3000rpm, 15min) after siphoning the supernatant, and the precipitate was vacuum-dried (45°C ) to obtain CPP product 1480g. The supernatant enters the nanofiltration device (the relative molecular mass cut off by the nanofiltration membrane is 300D) to concentrate, and the permeate is used to recover ethanol, and the concentrated (concentration is 150mg / ml) liquid is put on a DA201-C macroporous adsorption resin chromatographic column, washed with wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com