Molded article for clean room and method for producing same

A manufacturing method and clean room technology, applied in the field of molded products for clean rooms, can solve the problems of lack of wear resistance and pollution resistance, achieve excellent dimensional accuracy, excellent wear resistance, and suppress the generation of particles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0198] Raw materials (A) to (E) used in this example are as follows.

[0199] Cyclic olefin polymer (A):

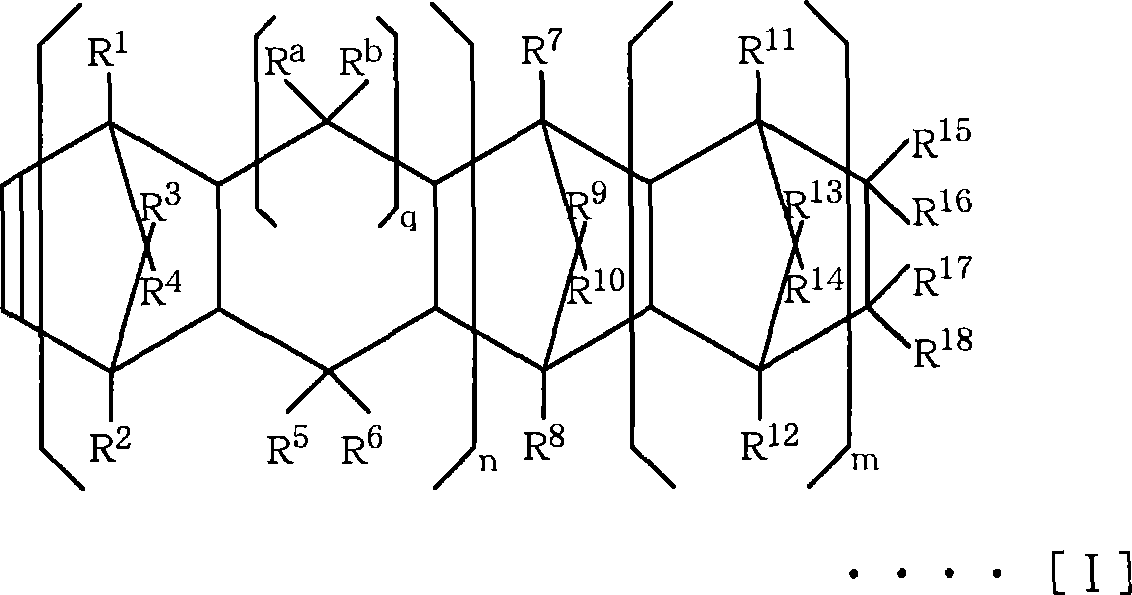

[0200] Ethylene and tetracyclines [4.4.0.1 2,5 .1 7,10 ]-3-dodecene (hereinafter sometimes abbreviated as "TCD-3") random copolymer (ethylene-TCD-3 random copolymer). by 13 The ethylene content measured by C-NMR was 62 mol%, the intrinsic viscosity [η] measured in decahydronaphthalene at 135°C was 0.60 dl / g, and the glass transition temperature (Tg) was 105°C. The MFR measured at 230° C. (measured under a load of 2.16 kg according to ASTM D1238) was 8.2 g / 10 minutes. The structural formula of TCD-3 is as follows.

[0201]

[0202] ·Soft copolymer (B):

[0203] Mitsui Chemicals Co., Ltd. ethylene-propylene random copolymer "P-0880". The ethylene content is 80 mol%, the glass transition temperature (Tg) is -54°C, the MFR (measured at 230°C under a load of 2.16kg according to ASTM D1238) is 0.4g / 10min, and [η] is 2.5dl / g, The density is 0.867g / cm 3 , the degree o...

Embodiment 2

[0228] Using the "pellets c" produced in Example 1, injection molding was performed in the same manner as in Example 1, and the total amount of outgassing, Taber abrasion, silicon wafer scratch abrasion, and surface resistivity were evaluated. These results are summarized in Table 1.

Embodiment 3

[0230] In Example 1, instead of supplying "pellet c" and carbon fiber to a twin-screw extruder produced by Plastic Engineering Research Institute Co., Ltd. for melt kneading, carbon fiber was not supplied, and only "pellet c" was supplied, while forced degassing Only by kneading, "granule e" was obtained. The raw material compounding ratio of "granule e" is the same as that of "granule c". Using "pellets e", the same procedure as in Example 1 was carried out, and the total amount of outgassing and the surface resistivity of the obtained injection molded article were measured. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com