Copolymer and dispersant

A technology of copolymers and summaries, applied in transportation and packaging, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as deterioration of processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

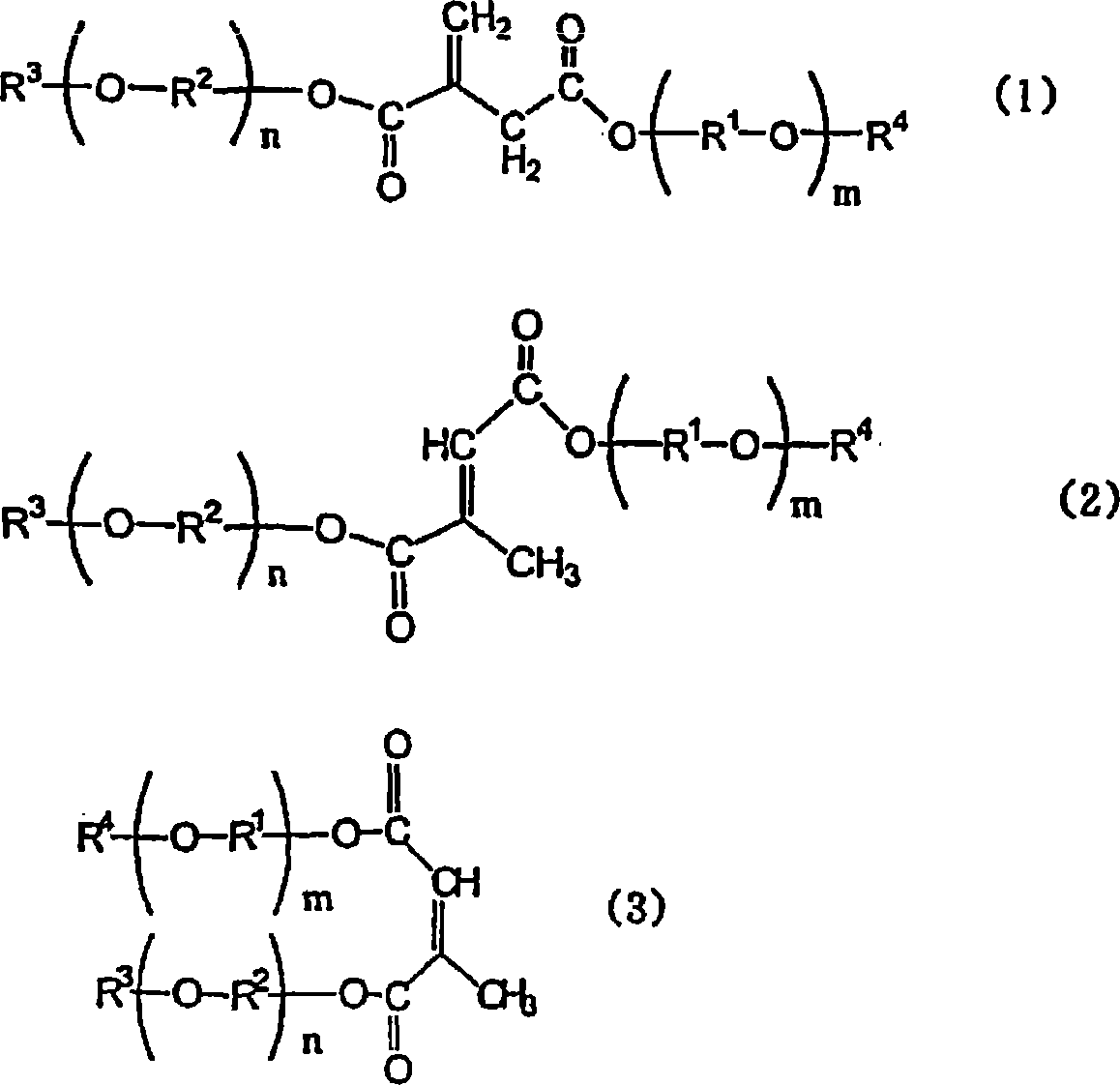

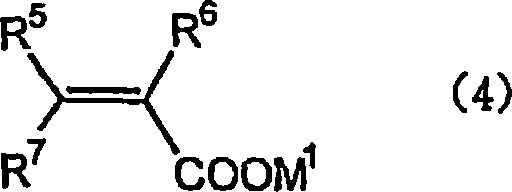

Method used

Image

Examples

Embodiment 1

[0085] (polymer synthesis)

[0086] In a reaction vessel equipped with a nitrogen conduit, a condenser, and a stirring device, 8.5 g of IT-1 obtained in Synthesis Example 1, 1.5 g of acrylic acid, 40 g of water, 0.23 g of 30% by mass of sodium hydroxide aqueous solution, 0.2 g of ammonium persulfate and 0.1 g of mercaptopropionic acid, and heated in an oil bath at 80° C. for 2 hours under nitrogen flow. Subsequently, 2.45 g of a 30% by mass aqueous sodium hydroxide solution was added to the resulting solution to obtain an aqueous solution of the copolymer (P-1) having a pH of 6.3. The solid content of this aqueous solution was 19.5% by mass. The weight average molecular weight of P-1 was 14,800.

Embodiment 2

[0088] (polymer synthesis)

[0089]In a reaction vessel equipped with a nitrogen conduit, a condenser, and a stirring device, 8.5 g of IT-2, 1.5 g of acrylic acid, 40 g of water, 0.23 g of 30% by mass of sodium hydroxide aqueous solution, 0.2 g of ammonium persulfate and 0.1 g of mercaptopropionic acid, and heated in an oil bath at 80° C. for 2 hours under nitrogen flow. Subsequently, 2.20 g of a 30% by mass aqueous sodium hydroxide solution was added to the resulting solution to obtain an aqueous solution of the polymer (P-2) having a pH of 6.2. The solid content of this aqueous solution was 19.7% by mass. The weight average molecular weight of P-2 was 22,800.

Embodiment 3

[0091] (polymer synthesis)

[0092] In a reaction vessel equipped with a nitrogen conduit, a condenser, and a stirring device, 13 g of water was placed and heated to 60° C. under nitrogen flow. Over a period of 1 hour, water was added dropwise by mixing 4.38 g of IT-3 obtained in Synthesis Example 3, 3.10 g of a 20% aqueous acrylic acid solution, 0.1 g of mercaptopropionic acid, and 5.00 g of a 0.1N aqueous sodium hydroxide solution. Solution A was formed, and at the same time, 2.06 g of 5% 2,2-azobis[2-(5-methyl-2-imidazolin-2-yl)]propane was added dropwise over a period of 1 hour and 30 minutes Dihydrogen chloride (dihydro-chloride). After the dropwise addition was completed, the resulting mixed solution was further heated for 1 hour, followed by mixing with 0.7 g of a 30-weight aqueous sodium hydroxide solution and 15 g of water to obtain a polymer (P-3) having a pH value of 6.3. aqueous solution. The solid content of this aqueous solution was 11.0% by weight. The weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com