Composite of poly m-phenylenediamine and nano silver and original position reduction preparing method thereof

A poly-m-phenylenediamine, m-phenylenediamine technology, applied in sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve the problems of complex process, power consumption, and the size of the electrode surface area cannot be carried out, reaching Equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Weigh 4.3256g (0.04mol) m-phenylenediamine and dissolve it in 100mL of 1mol / L hydrochloric acid solution, weigh 27.384g (0.12mol) ammonium persulfate and dissolve it in 100mL with a concentration of 1mol / L in the hydrochloric acid solution. The oxidant solution was added dropwise to the monomer solution at 30°C. The oxidant was added dropwise to start timing, and the reaction lasted for 24 hours. The black powdery polymer in doped state was obtained, soaked in ammonia water or sodium hydroxide solution, stirred for 24 hours, filtered, washed and dried to obtain poly-m-phenylenediamine in de-doped state. Yield 4.25g, yield 98.3%.

Embodiment 2

[0018] Weigh 4.3256g (0.04mol) m-phenylenediamine and dissolve it in 100mL of 1mol / L hydrochloric acid solution, weigh 9.126g (0.04mol) ammonium persulfate and dissolve it in 100mL with a concentration of 1mol / L in the hydrochloric acid solution. The oxidizing agent solution was added dropwise to the monomer solution at 65°C. The oxidant was added dropwise to start timing, and the reaction lasted for 24 hours. The black powdery polymer in doped state was obtained, soaked in ammonia water or sodium hydroxide solution, stirred for 24 hours, filtered, washed and dried to obtain poly-m-phenylenediamine in de-doped state. Yield 3.50g, yield 80.9%.

Embodiment 3~4

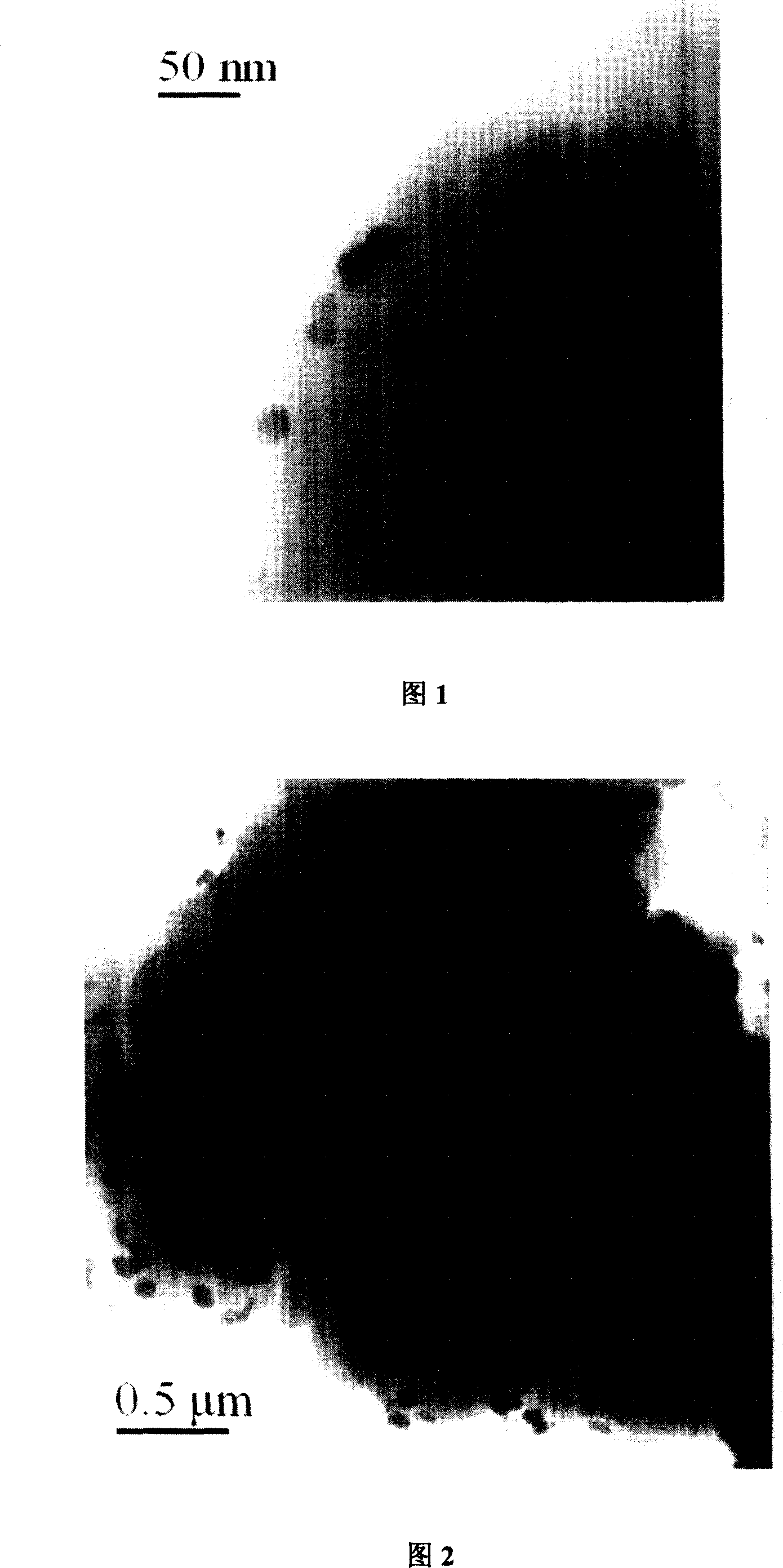

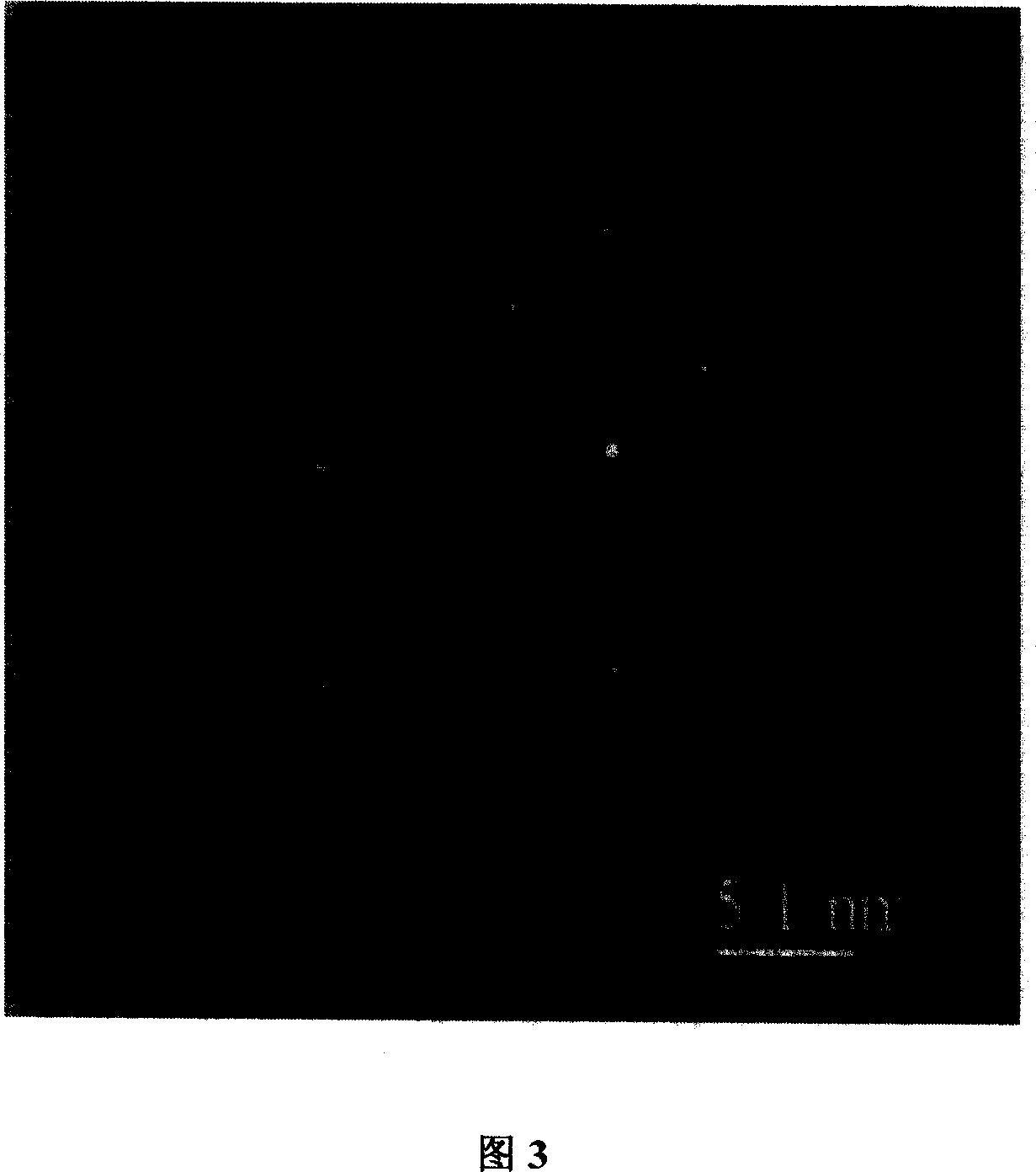

[0020] Get 50 mg of the product of Example 1, drop into 25 mL of silver ion solution with an initial concentration of 0.5 mmol / L at 30° C. and stir for 24 hours. ~20nm (Figure 1). Correspondingly, under the same conditions, changing the initial silver ion concentration to 2.5mmol / L, the particle size of the silver particles in the composite of poly-m-phenylenediamine and nano-silver is 50-100nm (Figure 2). Among them, some of them are single crystal particles, which can be confirmed by the electron diffraction pattern (Figure 3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com