Manufacture method for double-humped resonance coating optical fiber grating gas-sensing sensor

A technology of coating fiber grating and gas sensor, which is applied in the measurement of phase influence characteristics, etc., to achieve high refractive index sensitivity, long-distance telemetry, and high cost performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and all similar methods and similar changes of the present invention should be included in the protection scope of the present invention.

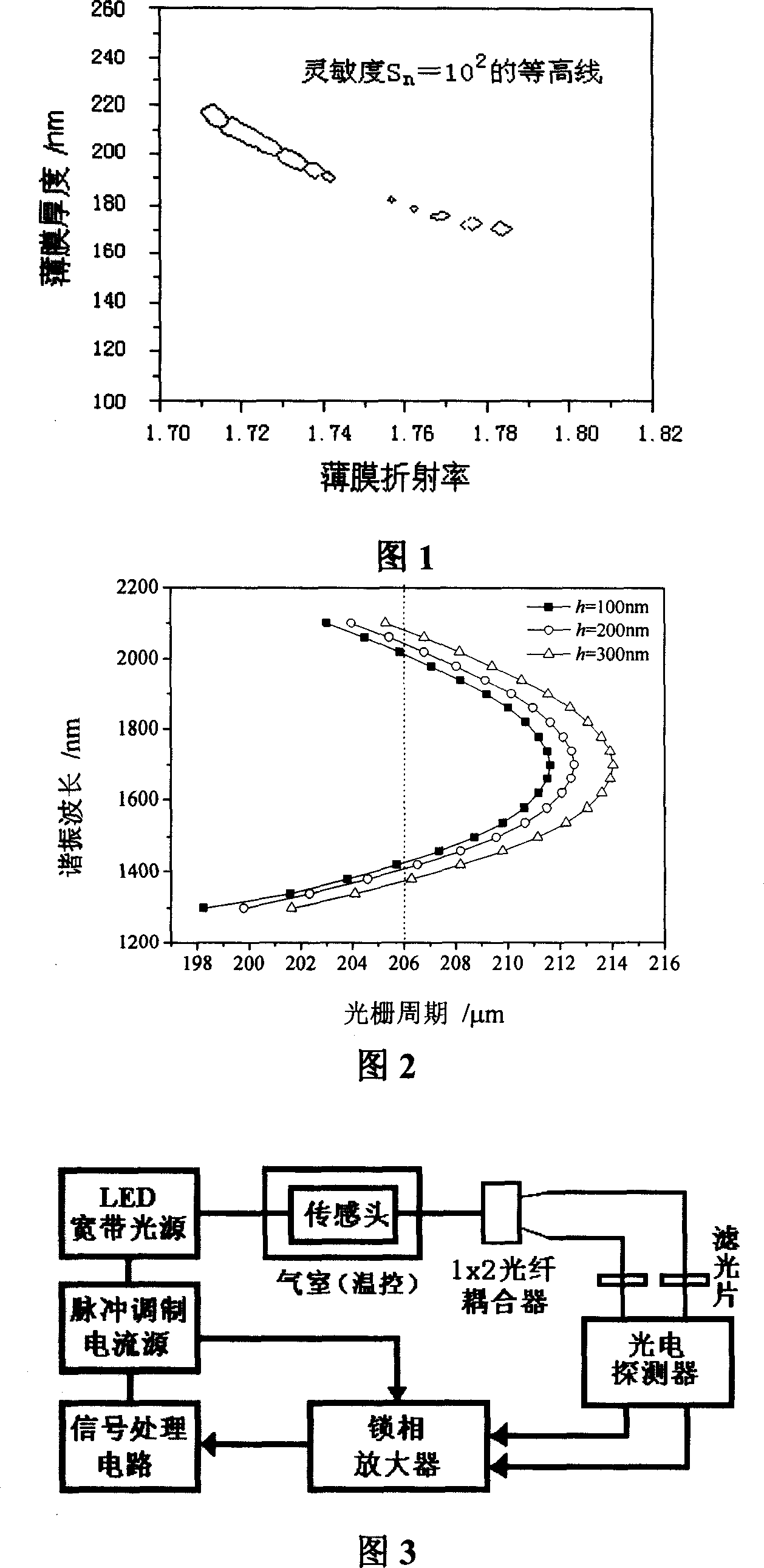

[0032] In order to maximize the variation of the distance between the double peaks of the transmission spectrum, it is necessary to select the appropriate optical parameters of the sensing film and the parameters of the grating to improve the sensitivity of the sensor. Therefore, there is a need for a new manufacturing method for long-period fiber grating thin film sensors. Compared with the traditional electrical block sensor, the optical thin film sensor has the characteristics of anti-electromagnetic interference, large dynamic range, high sensitivity and fast response; due to no electrical contact, it is especially suitable fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com