Electrolyte for the lithium ion battery

A lithium-ion battery and electrolyte technology, applied in secondary batteries, non-aqueous electrolyte batteries, organic electrolyte batteries, etc., can solve the problems of high production cost of fluorophosphate ester, low flame retardant efficiency of additives, limited flame retardant efficiency, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Dissolve 5.45g ethylene carbonate (EC) in 5.45g diethyl carbonate (DEC) and add 1.52g LiPF 6 1M LiPF 6 +EC / DEC (1:1wt) solution, and as a reference electrolyte, add 5wt% or 0.62g methyl methylphosphonate (DMMP) and 2wt% or 0.25g vinyl ethylene carbonate (VEC) , to obtain a flame retardant electrolyte.

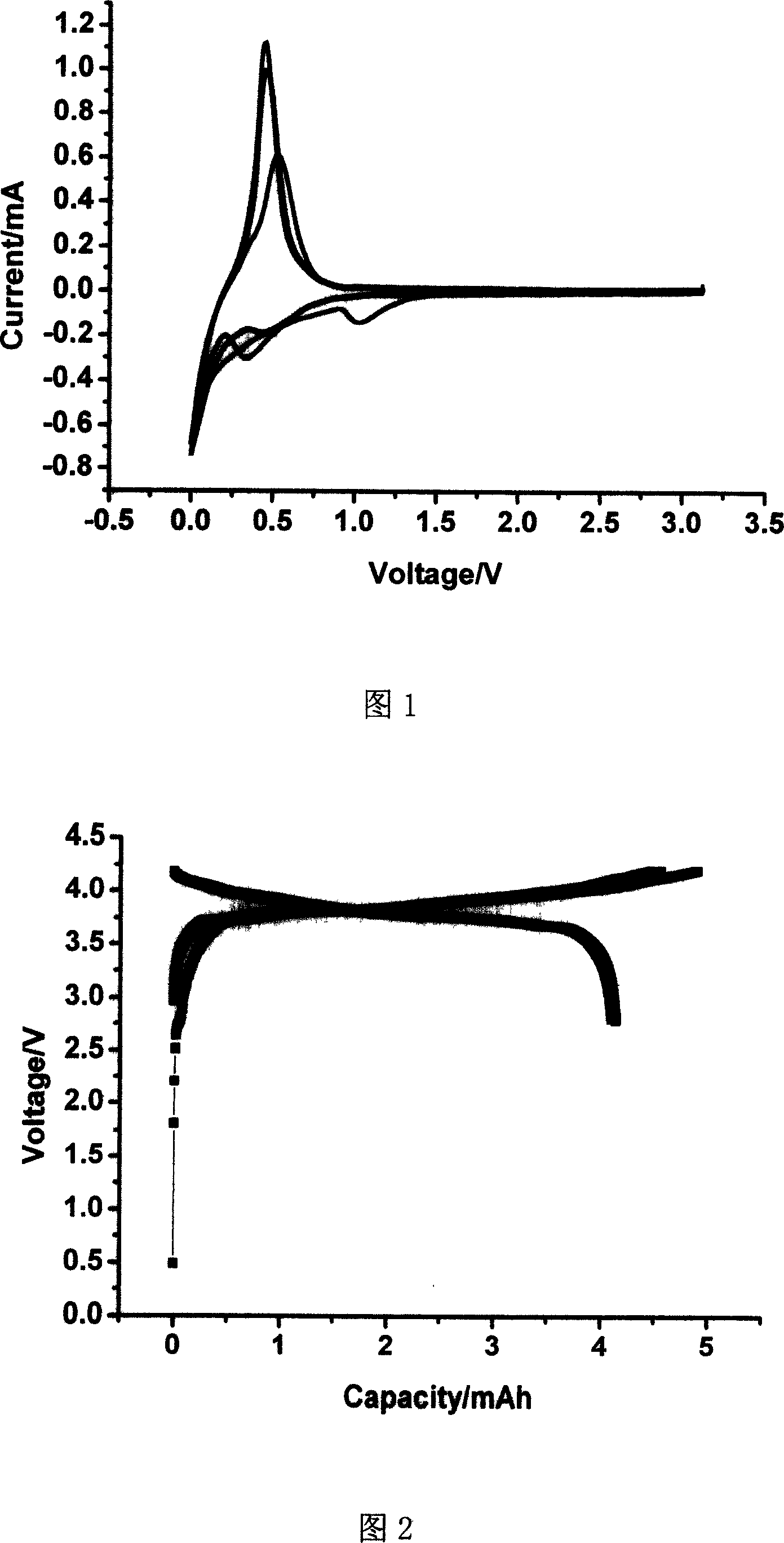

[0035] Graphite was used as the negative electrode, lithium sheet was used as the counter electrode, and Celgard2400 was used as the separator to assemble the negative electrode half-cell. Figure 1 is the curve obtained from the cyclic voltammetry test. The reduction peak at 1.2-1.0V in the figure is the reduction of VEC to form a film, which protects the graphite electrode and prevents the peeling of the graphite structure caused by DMMP.

[0036]Using graphite as the anode, LiCoO 2 As the positive electrode, Celgard2400 as the separator, assembled into a full battery. at 0.2mA / cm 2 The capacity-voltage curve obtained by charging and discharging three times at a c...

Embodiment 2

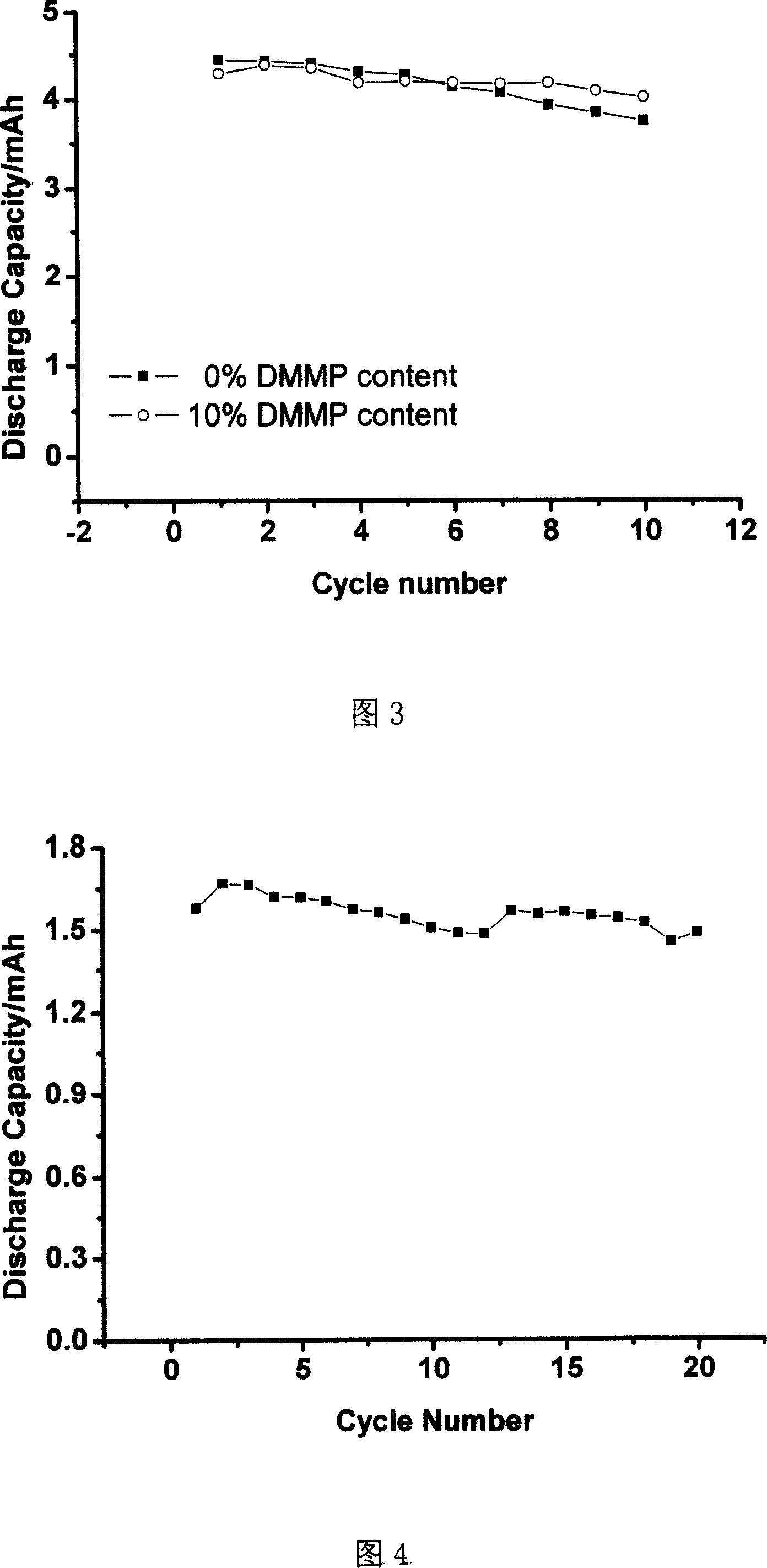

[0038] With the 1M LiPF that makes in embodiment 1 6 +EC / DEC (1:1wt) solution was used as a reference electrolyte, and 10 wt%, ie, 1.24g DMMP was added to prepare a flame-retardant electrolyte. Using MCMB as the anode, LiCoO 2 As the positive electrode, Celgard2400 as the separator, assembled into a full battery. Fig. 3 is the cycle performance curve of the full battery containing the reference electrolyte and the flame-retardant electrolyte. The performance of comparative benchmark electrolyte and flame retardant electrolyte is shown in the table below:

[0039] First discharge capacity

Embodiment 3

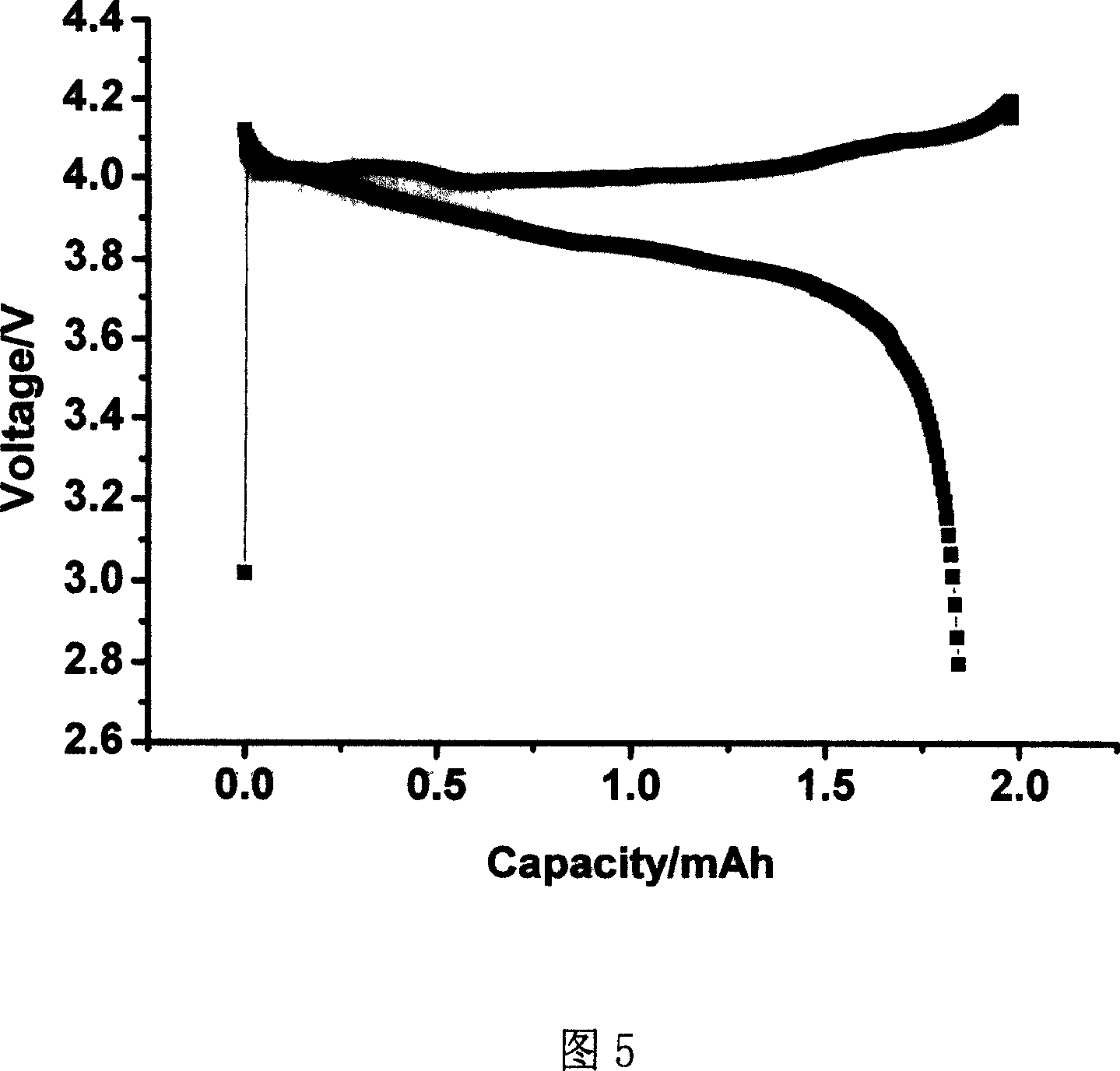

[0041] Mix 2.30gDMMP, 1.15gEC and 1.15gDEC, add 0.608gLiPF to the mixed solvent 6 , dubbed 1M LiPF 6 +DMMP / EC / DEC (2:1:1wt) electrolyte. Using LiCoO 2 As the positive electrode, a lithium sheet is used as the counter electrode, and Celgard3501 is used as the diaphragm to assemble the positive electrode half-cell. The discharge capacity-cycle number curve of the constant current charge and discharge test is shown in Figure 4, and the positive half-cell performance of the flame-retardant electrolyte and the reference electrolyte in Example 4 is shown in the following table:

[0042] First discharge capacity

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com