High-safety electrolyte and preparation method thereof

An electrolyte and safe technology, applied in the field of lithium-ion batteries, can solve problems such as hindering large-scale production, high battery manufacturing costs, and affecting battery electrochemical performance, so as to reduce self-extinguishing time, improve safety performance, and stabilize SEI film structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

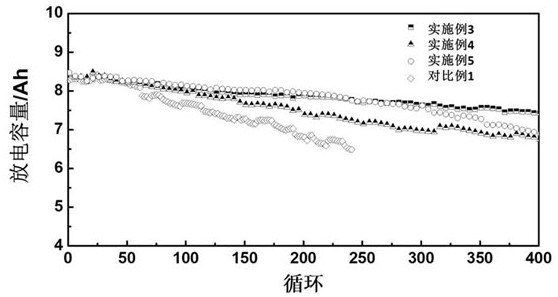

Examples

Embodiment 1

[0029] A high-safety electrolyte, characterized in that: in terms of mass percentage, the electrolyte includes the following components: 70-90% wt of organic solvent of electrolyte, 5-20% wt of lithium salt, and 0.1-10% of film-forming additive wt, compound additive 0.1-10%wt.

[0030] Among them, the composite additives include flame retardant additives, silane coupling agents, inorganic nano oxides; the organic solvents of the electrolyte are ethylene carbonate, propylene carbonate, dimethyl carbonate, fluoroethylene carbonate, diethyl carbonate, methyl carbonate One or a combination of ethyl esters, the organic solvent content of the electrolyte is 75-85%wt; the lithium salt is one or a combination of lithium hexafluorophosphate, lithium bisfluorosulfonimide, and lithium difluorooxalate borate; film forming The additive is one of vinylene carbonate, vinyl sulfite, tris(trimethylsilane) phosphate, vinyl sulfate or a combination thereof.

[0031] Among them, the inorganic na...

Embodiment 2

[0033] A method for preparing a high-safety electrolyte, comprising the following steps:

[0034] (1) Add flame retardant additives, silane coupling agents, and inorganic nano-oxides into organic solvents, react at 30-100°C for 2-10 hours, centrifuge and dry to obtain composite additives.

[0035] (2) The organic solvent and additives of the electrolyte are dewatered respectively, and the water content thereof is controlled to be lower than 20 ppm.

[0036] (3) the electrolyte organic solvent (one of ethylene carbonate, propylene carbonate, dimethyl carbonate, fluoroethylene carbonate, diethyl carbonate, ethyl methyl carbonate or Its combination) is placed in an anhydrous and oxygen-free glove box, and is prepared into a blank solvent.

[0037] (4) Add 5 to 20% lithium salt (one of lithium hexafluorophosphate, lithium bisfluorosulfonimide, lithium difluorooxalate borate or a combination thereof) to the blank solvent in step (3) by mass percentage, 0.1-10% film-forming additi...

Embodiment 3

[0040] A method for preparing a high-safety electrolyte, comprising the following steps:

[0041](1) Phosphate-tris-(2,2,2,-trifluoroethyl) ester, 3-(2-aminoethylamino)propyltrimethoxysilane and silicon dioxide in a mass ratio of 2:1: 7 Mix evenly in 20ml of absolute ethanol by ultrasonication for 30min, react in an oven at 90°C for 8h, centrifuge at a high speed and dry to obtain a composite additive.

[0042] (2) The organic solvent of the electrolyte: 20g ethylene carbonate, 10g fluoroethylene carbonate, 20g diethyl carbonate, 50g ethyl methyl carbonate and additives were dewatered respectively to control the water content below 20ppm.

[0043] (3) Place the organic solvent of the electrolyte solution removed from water in step (2) in an anhydrous and oxygen-free glove box to prepare a blank solvent.

[0044] (4) Add lithium salt to the blank solvent of step (3): 12.5g lithium hexafluorophosphate, 1.25g lithium difluorooxalate borate, 1.25g lithium bisfluorosulfonyl imide,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com