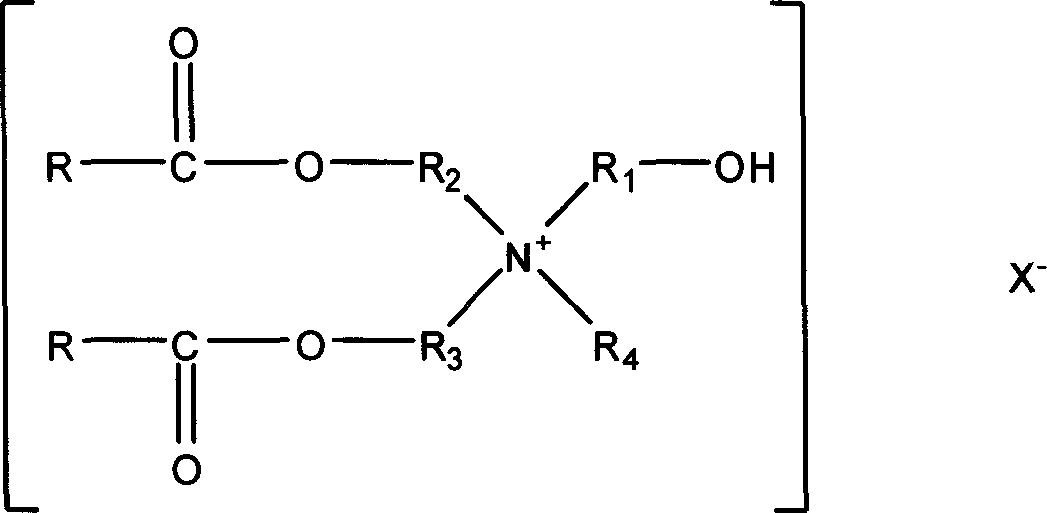

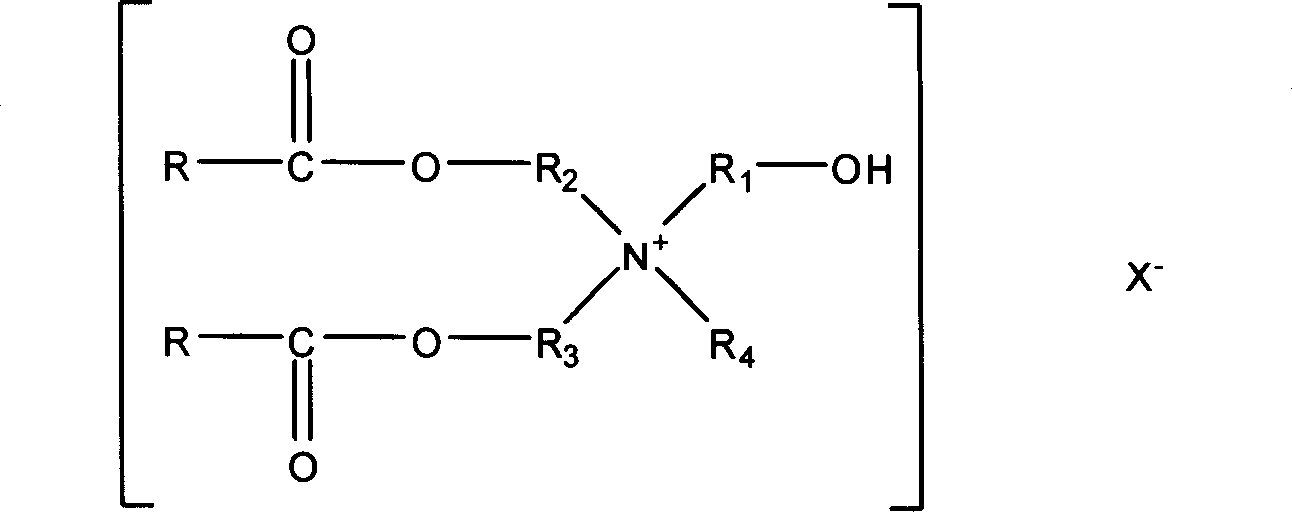

Synthesis process of ester quaternary ammonium salt

The technology of an ester quaternary ammonium salt and a synthesis method is applied in the synthesis field of the ester quaternary ammonium salt, and achieves the effects of good selectivity, low ecological toxicity and improved grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Take by weighing 840g stearic acid and join in the four-necked bottle of 2000mL, under N 2 Under atmospheric conditions, stir and heat up to 80°C. After all of them are melted, add 2g of phosphorous acid and 248g of triethanolamine, stir and heat up to 155°C. After 9 hours of heat preservation, the acid value of the product is measured to be 2.5mgKOH / g, and the reaction is terminated. . Cool the reaction mixture to 80°C, stop feeding N 2 Gas, and 199g of dimethyl sulfate continuously enter the mixing reactor, carry out continuous quaternization reaction, control 80 ℃ of reaction for 1.5 hours, measure the free amine content in the product to be 5mgKOH / g, can stop reaction.

Embodiment 2

[0023] Take by weighing 840g hydrogenated tallow acid and join in the four-necked bottle of 2000mL, under N 2 Stir under atmospheric conditions and heat up to 80°C. After all of them are melted, add 2g of phosphorous acid and 198g of methyldiethanolamine, stir and heat up to 180°C. After 7 hours of heat preservation, the acid value of the product is 2.5mgKOH / g. Abort the reaction. Cool the reaction mixture to 80°C, stop feeding N 2 Gas, and 199g dimethyl sulfate continuously enter the mixing reactor, carry out continuous quaternization reaction, control 80 ℃ reaction for 1.5 hours, measure the free amine content in the product to be 5mgKOH / g, can stop reaction.

Embodiment 3

[0025] Weigh 840g of tallow acid and add it to a 2000mL four-necked bottle, stir and heat up to 80°C under N2 atmosphere, after all of them are melted, add 2g of phosphorous acid and 248g of triethanolamine, stir and heat up to 200°C, keep warm for 6 After one hour, the acid value of the product was measured to be 2.5 mgKOH / g, and the reaction was terminated. Cool the reaction mixture to 80°C, stop feeding N 2 Gas, enters mixing reactor continuously together with 199g dimethyl sulfate, carries out continuous quaternization reaction, reacts 1.5 hours, records free amine content in the product and is 5mgKOH / g, can stop reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com