Prepn process of copolyester capable of being dyed deeply with cationic dye

A preparation process, cationic technology, applied in the direction of single-component polyester rayon, dyeing, textile and papermaking, etc., can solve problems such as uncomfortable brightness and reflection, self-aggregation of titanium dioxide, broken ends, etc., to improve spinning conditions, Good rheology, reducing the effect of broken ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

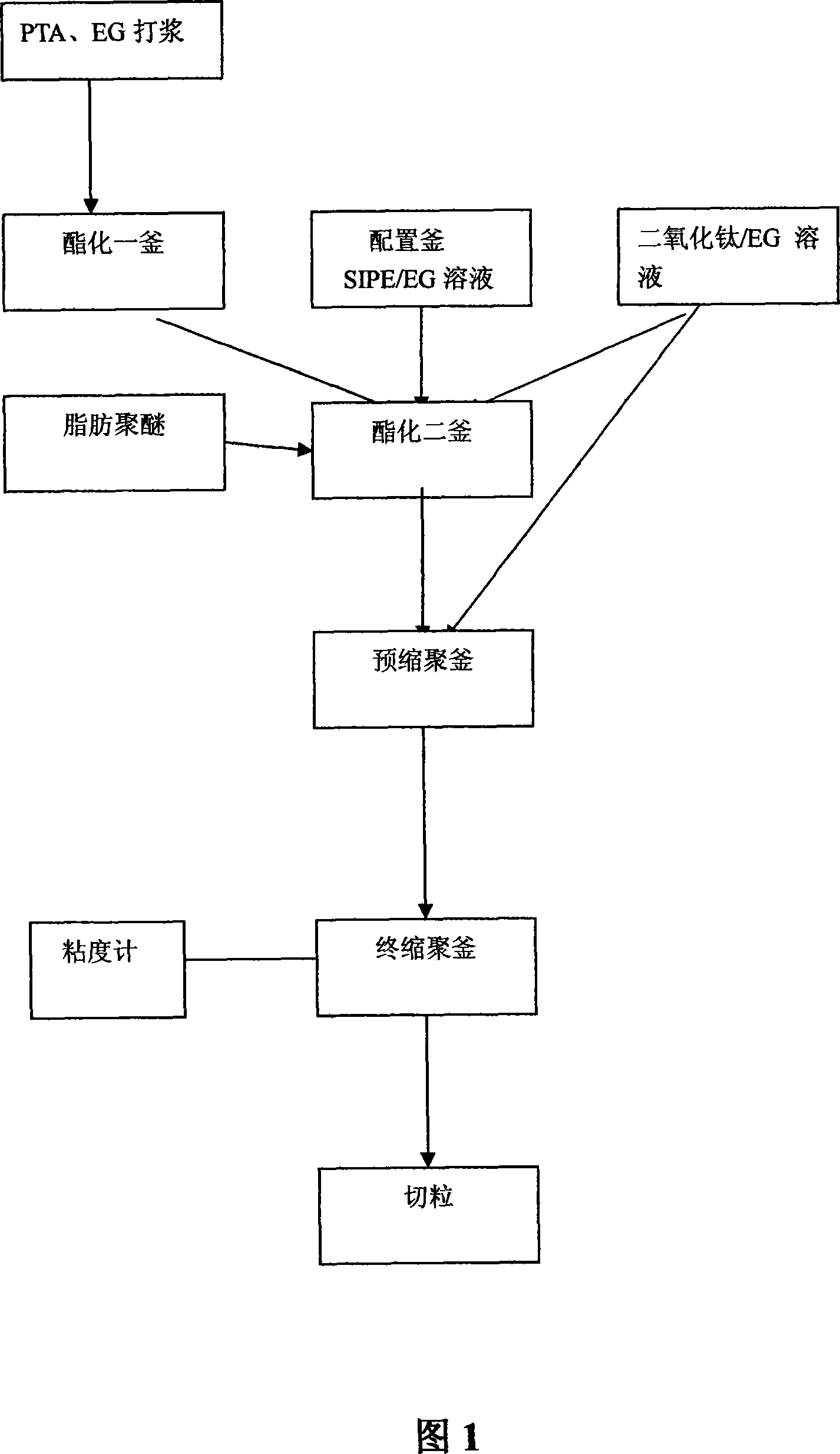

Method used

Image

Examples

Embodiment 1

[0012] The configuration of the SIPE solution described in Embodiment 1, Embodiment 2, Embodiment 3, and Embodiment 4: first add EG (ethylene glycol) 900L in the preparation kettle, heat up to 100°C for dehydration for 30 minutes and then drop into isophthalic acid Sodium Dimethyl Ester-5-Benzene Sulfonate (SIPM) 475Kg and Calcium Acetate 1.2kg Sodium Acetate 7kg. The temperature is raised to control the top temperature of the tower at about 65°C to receive about 115L of methanol. Add EG to adjust the specific gravity to 1.2g / cm 3 . Cool down to 50-70°C, stir and store for later use.

Embodiment 1

[0014] Put 3000kg of terephthalic acid and 1350kg of ethylene glycol into the first esterification kettle, carry out the esterification reaction at 250°C, after dehydration of 650L, introduce the second esterification kettle and cool down to 240°C, add 450LSIPE solution, 35kg~60kg of polyethylene glycol in sequence Diol, then collect EG100L. Import into the pre-shrinking tank, at 250-280°C, build a vacuum to 1KPa, stir and react for 2 hours, then stir and react under 60Pa in the final shrinking tank for about 100 minutes, discharge and pelletize.

Embodiment 2

[0016] Put 3000kg of terephthalic acid and 1350kg of ethylene glycol into the first esterification kettle, and carry out the esterification reaction at 250°C. After dehydration of 650L, they are introduced into the second esterification kettle, and the temperature is lowered to 240°C. Add 420LSIPE solution, 35kg~60kg polyethylene glycol Alcohol and 20L of 10% fiber-grade titanium dioxide solution, and then collect EG100L. Import into the pre-shrinking tank, at 250-280°C, build a vacuum to 1KPa, stir and react for 2 hours, then stir and react in the final shrinking tank below 60Pa for about 100 minutes, discharge and pelletize.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com