Method for making amber cavity and apparatus by optical fiber method

A production method and optical fiber technology, which is applied in the field of extrinsic optical fiber method-percavity sensor production, can solve the problems that the quartz capillary and the optical fiber cannot be completely sealed, the angular distribution of the solder joint width is uneven, and the sensor is slightly bent. , to achieve the effects of small bending deformation, uniform distribution, and small hysteresis error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The best embodiment of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

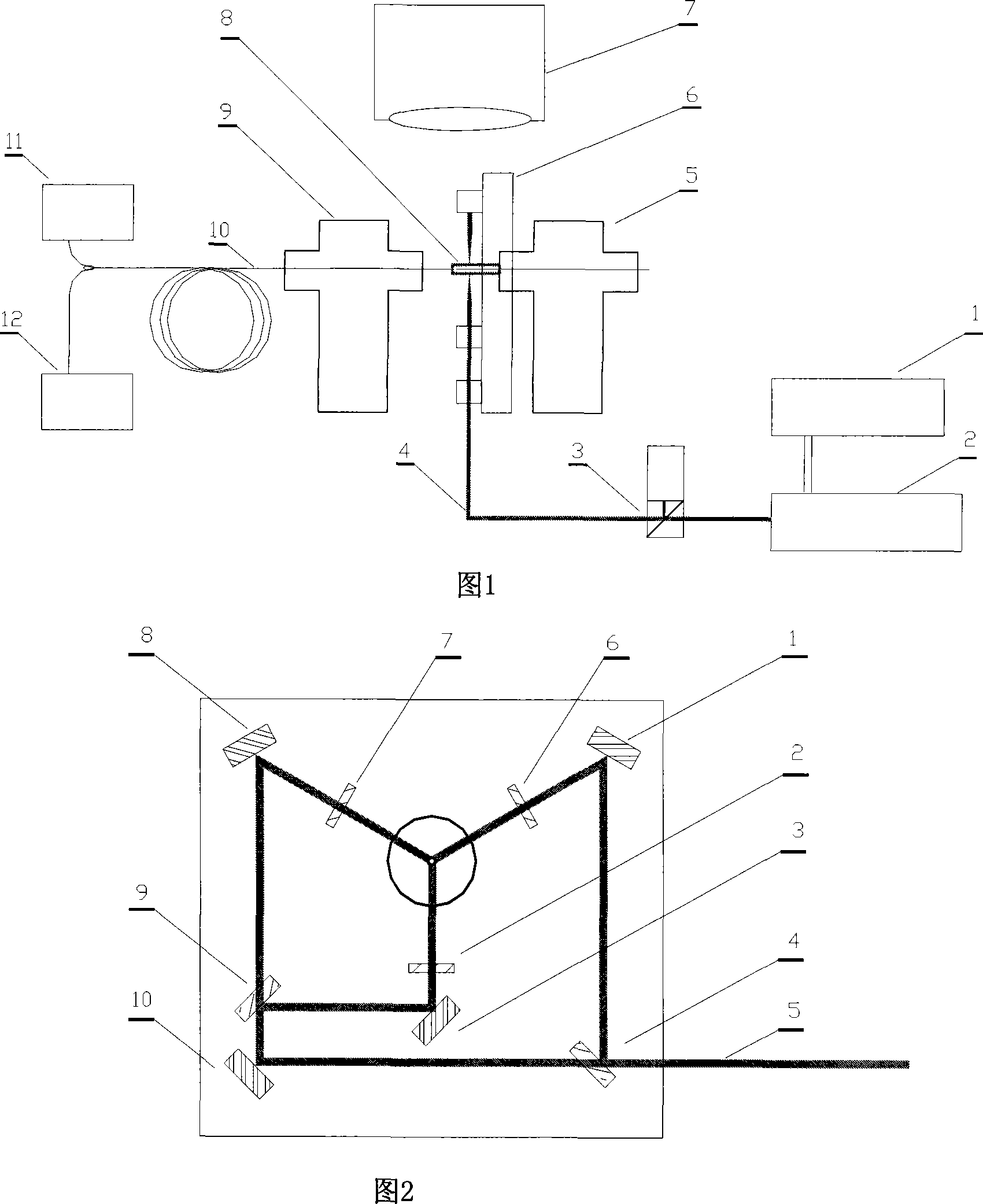

[0014] First, adjust the five-dimensional adjustment frame 5 that holds the optical fiber, so that the quartz capillary is in three beams of high-frequency CO 2 At the point of intersection of the pulsed laser. Use the He-Ne laser indicator light 3 in Figure 1 to adjust CO 2 Laser light path, to ensure three beams of CO 2 The intersection angle of the pulsed laser is 120 degrees, so that the three beams of CO 2 The pulsed laser light intersects at the same point on the axis of the quartz capillary 8 after being focused by a cylindrical lens. Adjust the five-dimensional adjusting frame 9 holding the optical fiber, monitor the optical fiber 10 through the quartz capillary 8 through the video microscope 7, adjust the five-dimensional adjusting frame 5 holding the quartz capillary 8 along the axis of the quartz capillary, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com