Method and instrument for detecting aggregate relative density and water absorbing rate

A technology of relative density and test method, which is applied in the direction of material absorption weighing and material analysis by observing sunken objects. problems, to achieve the effect of shortening test and manual intervention time, good accuracy and repeatability, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

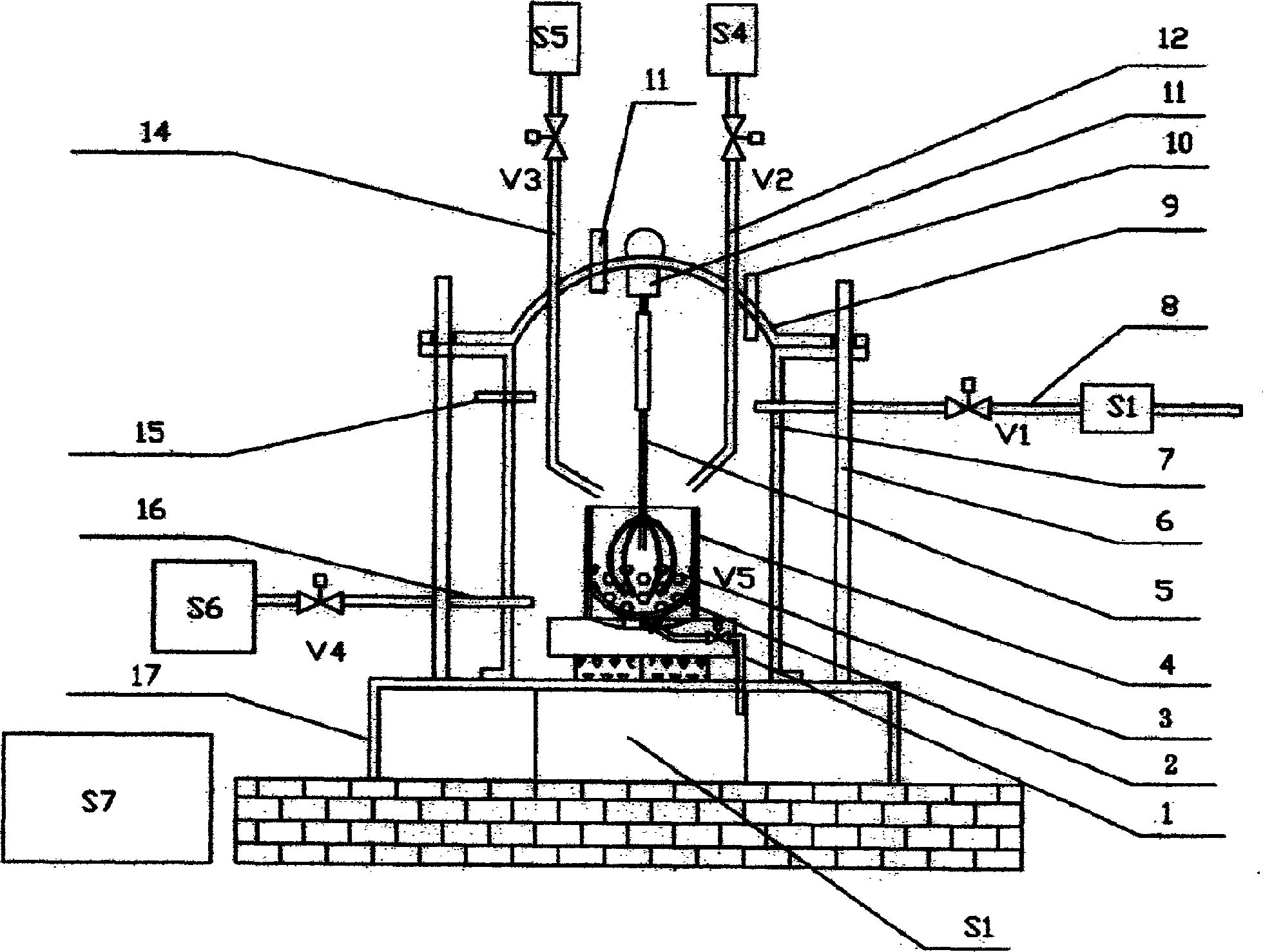

[0048] The method and apparatus structure of the present invention will be described in detail below in conjunction with the accompanying drawings of the embodiments of the present invention. The present invention can be implemented in many ways, and is not limited to the form described here.

[0049] Referring to Fig. 1, Fig. 1 is the embodiment diagram of the overall structure of the apparent relative density, bulk volume relative density and water absorption rate of the test coarse and fine aggregates of the present invention.

[0050] The invention provides a method, an instrument and a system to test the apparent relative density, bulk relative density and water absorption of coarse and fine aggregates.

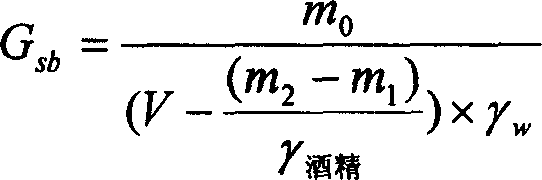

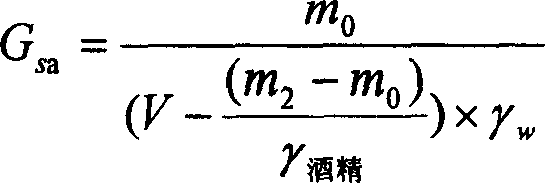

[0051] This method consists of the following steps: (a) put the aggregate in an oven at a certain temperature and dry it to a constant weight, cool it to room temperature, weigh a sample of a certain quality, and record the mass; (b) put the aggregate in a vacuum In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com