Secondary battery set enhanced with glass fiber reinforced resin and its manufacture

A technology for battery packs and manufacturing methods, which is applied to battery pack parts, secondary batteries, circuits, etc., can solve problems such as limiting the application of battery packs, and achieve the effects of reducing material costs, increasing specific energy, and saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

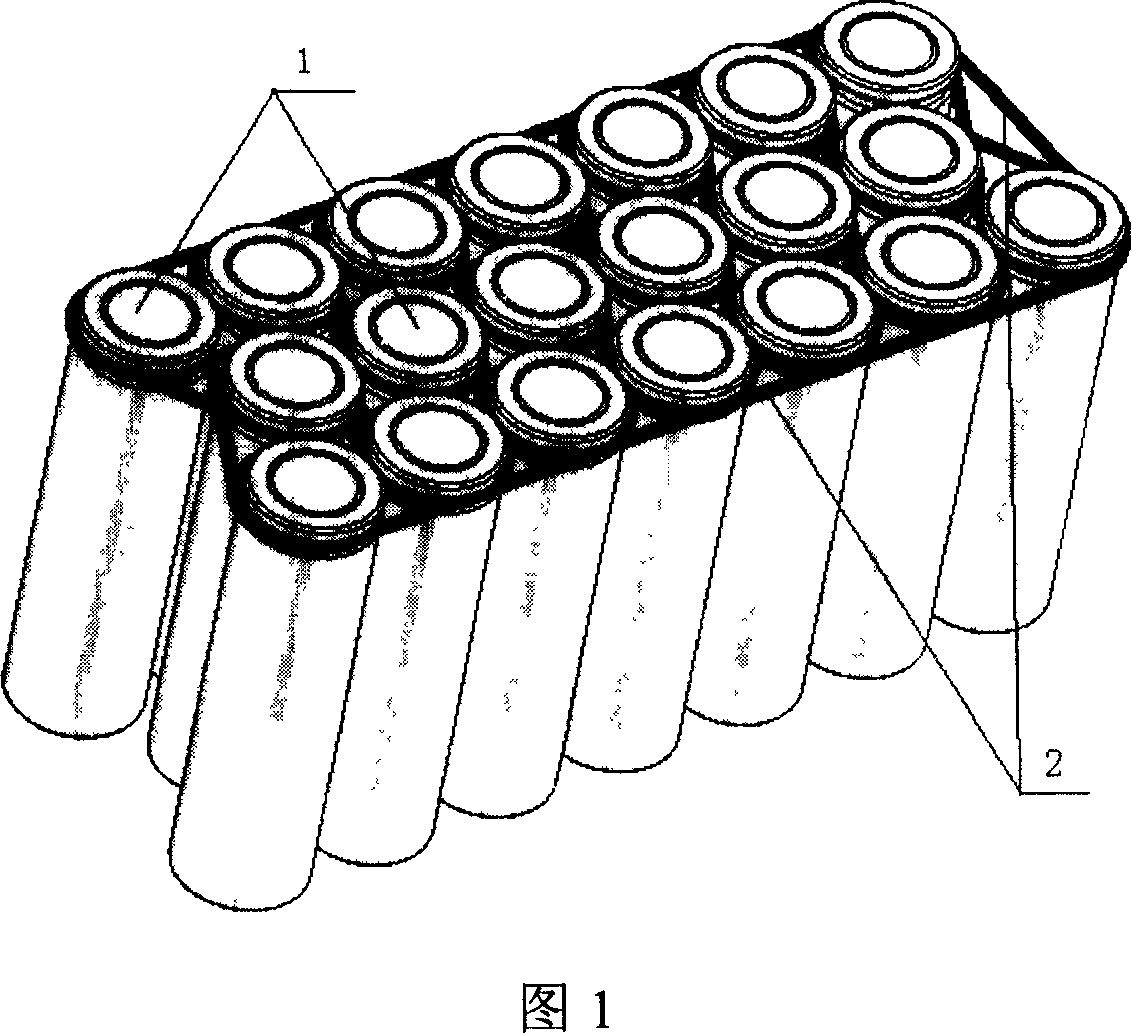

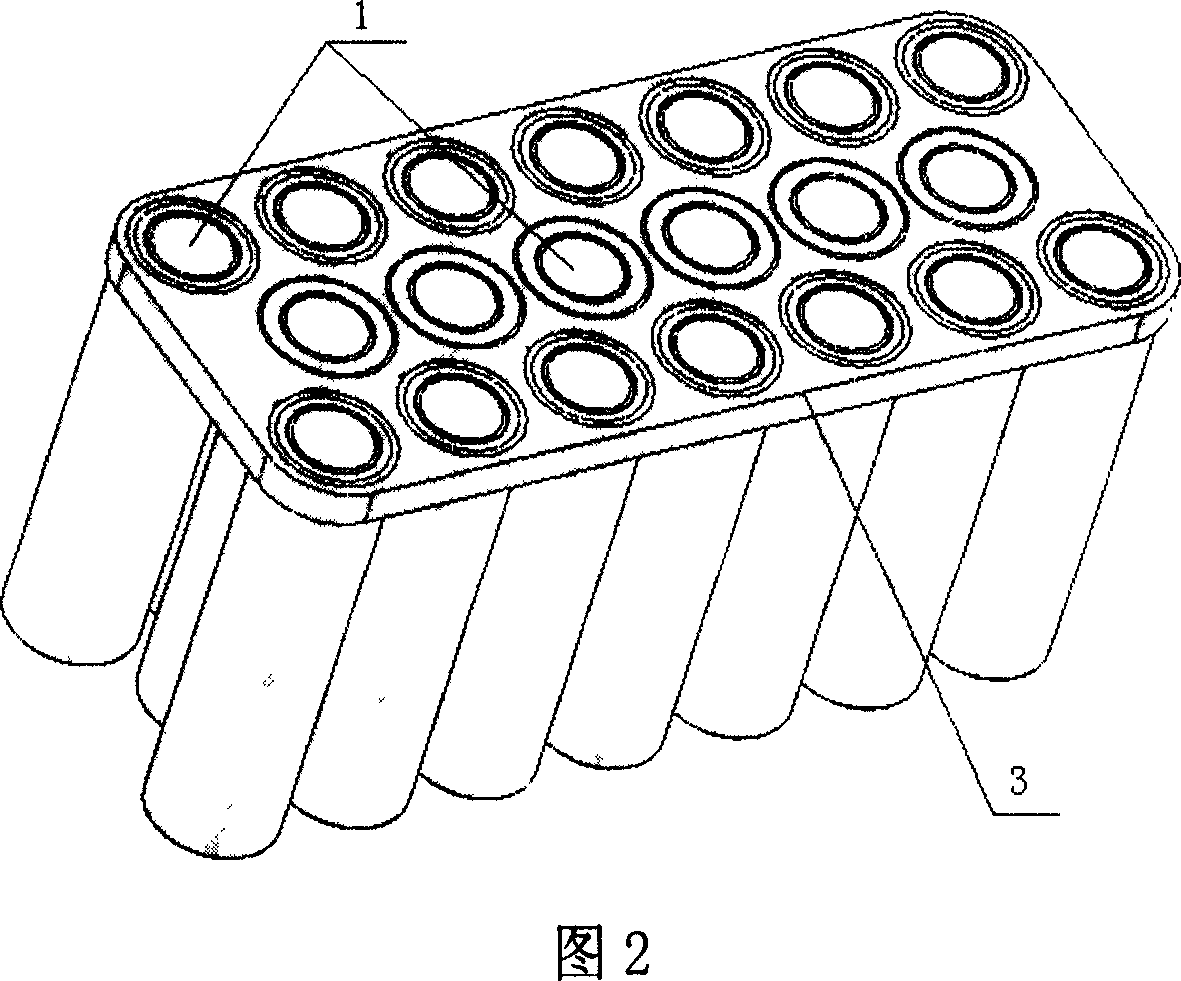

[0057] Embodiment 1 As shown in Fig. 1, Fig. 2 and Fig. 3, with 20 capacity 2200mAh, diameter is about 18mm, the lithium ion battery 1 of height is about 65mm is monomer, uses glass fiber 2 (Du Pont product, trade name Nomex ) around the battery rolling groove one by one, use a mold to cover the battery head tightly, pour epoxy resin 3 as shown in Figure 2, heat and cure at 45°C, and assemble into a 3.6V 116.6Ah lithium-ion battery pack. The epoxy resin used is Jeffco3176, its softening point HDT is 195F (ASTM D648-264) (about 90°C). In the way of filament wound battery, as shown in FIG. 1 , the glass fiber wire 2 extends outward with the equilateral triangle formed by three single batteries 1 as the basic unit. Finally, the single cells 1 can be connected with the conductive connecting piece 4 (as shown in FIG. 4 ).

[0058] In Example 2, 53 lithium-ion batteries with a capacity of 2200mAh, a diameter of about 18mm, and a height of about 65mm were used as monomers to form a ...

Embodiment 3

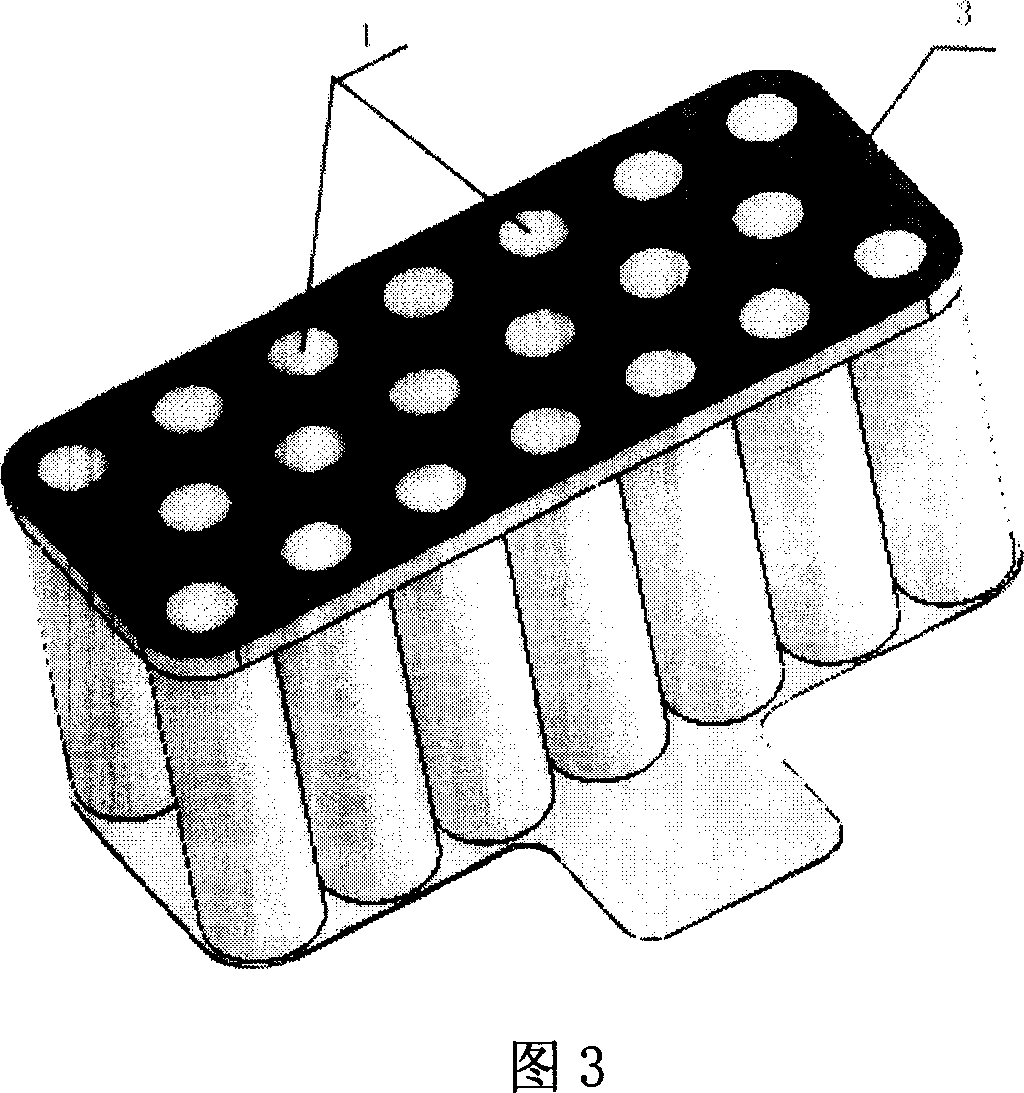

[0059] Example 3 As shown in Figure 3, 20 lithium-ion batteries with a capacity of 3000mAh, a diameter of about 27mm, and a height of about 65mm are used as monomers to form a 3.6V / 60Ah lithium-ion battery pack in the same way as in Example 1. .

Embodiment 4

[0060] Example 4 As shown in Figure 4, 60 lithium-ion batteries with a capacity of 3.0Ah, a diameter of about 26mm, and a height of about 70mm are used as monomers to form a 10.8V / 60Ah lithium-ion battery in the same way as in Example 1. Group.

[0061] The above four battery packs were tested according to the vibration resistance test method of the electric vehicle battery mentioned above, and all of them met the standard requirements.

[0062] The above-mentioned embodiments 1 to 4 used lithium-ion battery cells, but the storage battery pack and its manufacturing method of the present invention are not limited to the use of lithium-ion batteries, and the effects of the present invention can also be obtained by using nickel-metal hydride batteries or other storage batteries. The shape of the battery is not limited to the cylindrical shape, and the effect of the present invention can also be obtained by adopting this method for batteries of square, rhombus or other shapes. Fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com