Method of preparing 2-thiophenyl-5-propionyl phenyl acetic acid

A technology of propionylbenzene and phenylthio, which is applied in the field of preparation of polycyclic aromatic hydrocarbon derivatives, can solve the problems of unreported preparation methods, and achieve the effects of high product yield, simple process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

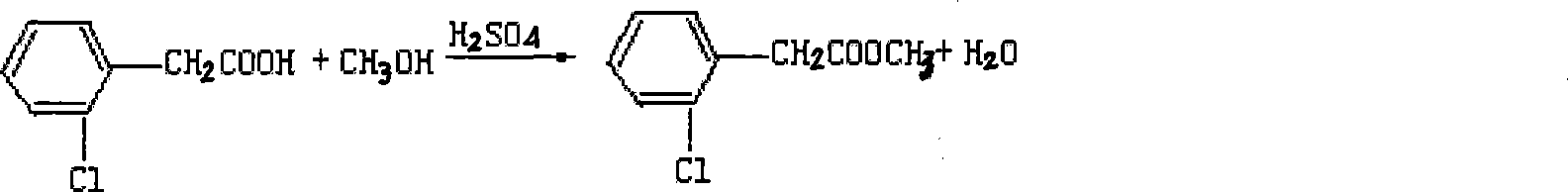

[0025] ①Put 1200g of methanol with a concentration > 99% and 1000g of o-chlorophenylacetic acid into a 2000ml reactor, stir until completely dissolved, then add 100g of concentrated sulfuric acid with a concentration ≥ 98%, and heat up to methanol reflux. After reflux for 2.5 hours, recover methanol ; Add 300g of water after the recovery of methanol, stir, static layering, and wash with 20% soda ash, then wash with water several times until neutral, layer into the intermediate product barrel, add NaSO 4 Suction dry. The yield of methyl o-chlorophenylacetate in this step is more than 92%;

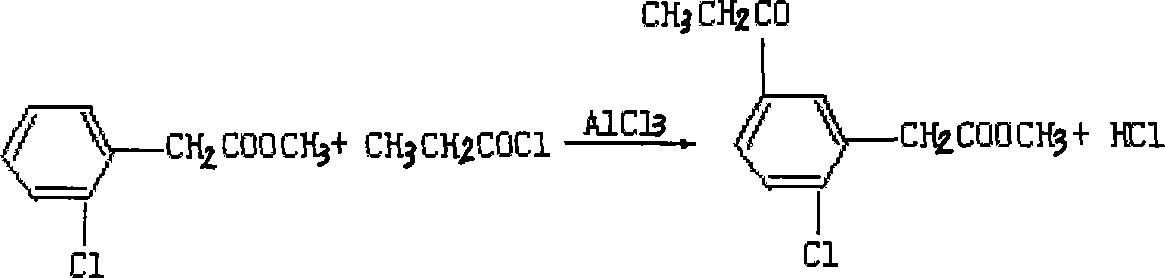

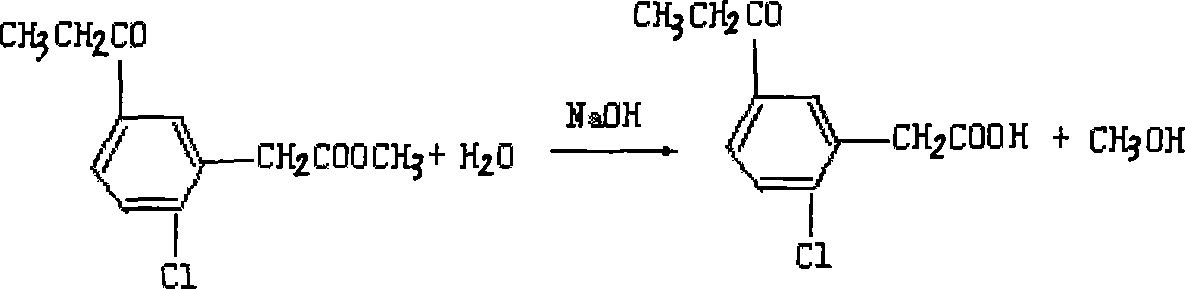

[0026] ② Add AlCl to the 500ml reactor 3 220g, slowly drop 100g propionyl chloride into the reactor, cool with water, and control the temperature below 60°C; Below 60°C; after the dropwise addition, add 360g of dichloroethane, raise the temperature to reflux, keep the temperature for 2 hours, wash with water, stir, and separate the water to obtain 360g of brown emulsifiable oil. Distilla...

Embodiment 2

[0030] In 1. of embodiment 1, change the vitriol oil and methyl alcohol consumption, the vitriol oil increases to 120g, and methyl alcohol increases to 1500g, and all the other repeat embodiment 1.

Embodiment 3

[0032] In ① of embodiment 1, change the concentrated sulfuric acid and methanol consumption, the concentrated sulfuric acid is reduced to 80g, and methyl alcohol is reduced to 1000g, and all the other repeat embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com