High-resolution X-ray image enhancer

A high-resolution, image intensifier technology, applied in the direction of cathode ray/electron beam tube shell/container, image conversion/image magnification tube, screen tube, etc., can solve the problem of low X-ray transmittance, serious scattering, contrast Poor and other problems, to achieve the effect of improving spatial resolution, small scattering, and improving contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

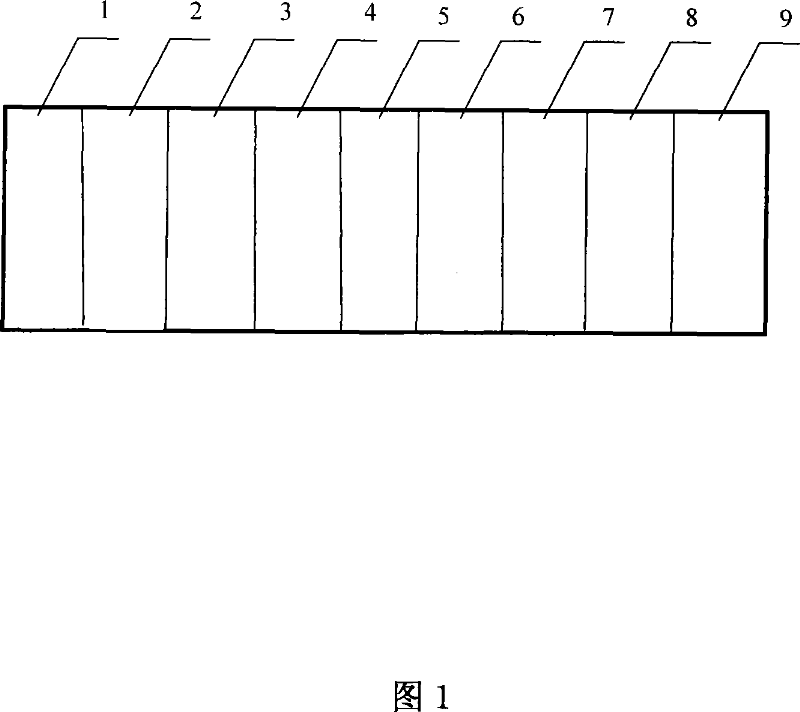

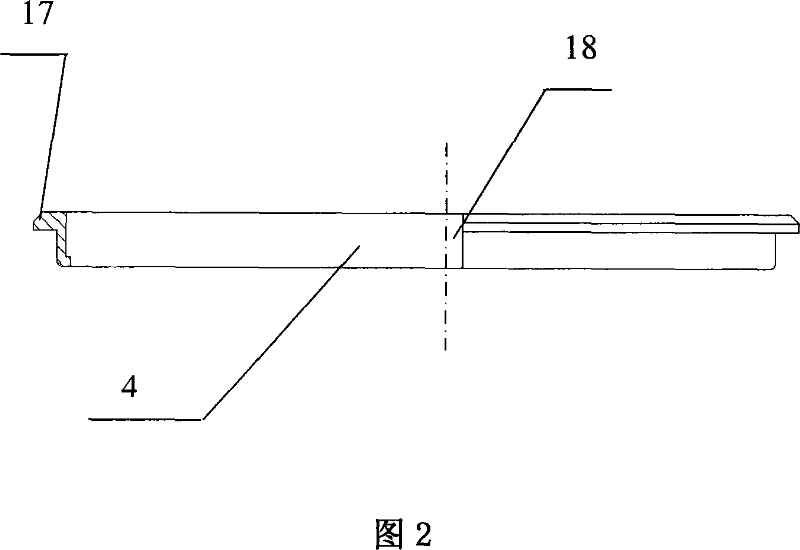

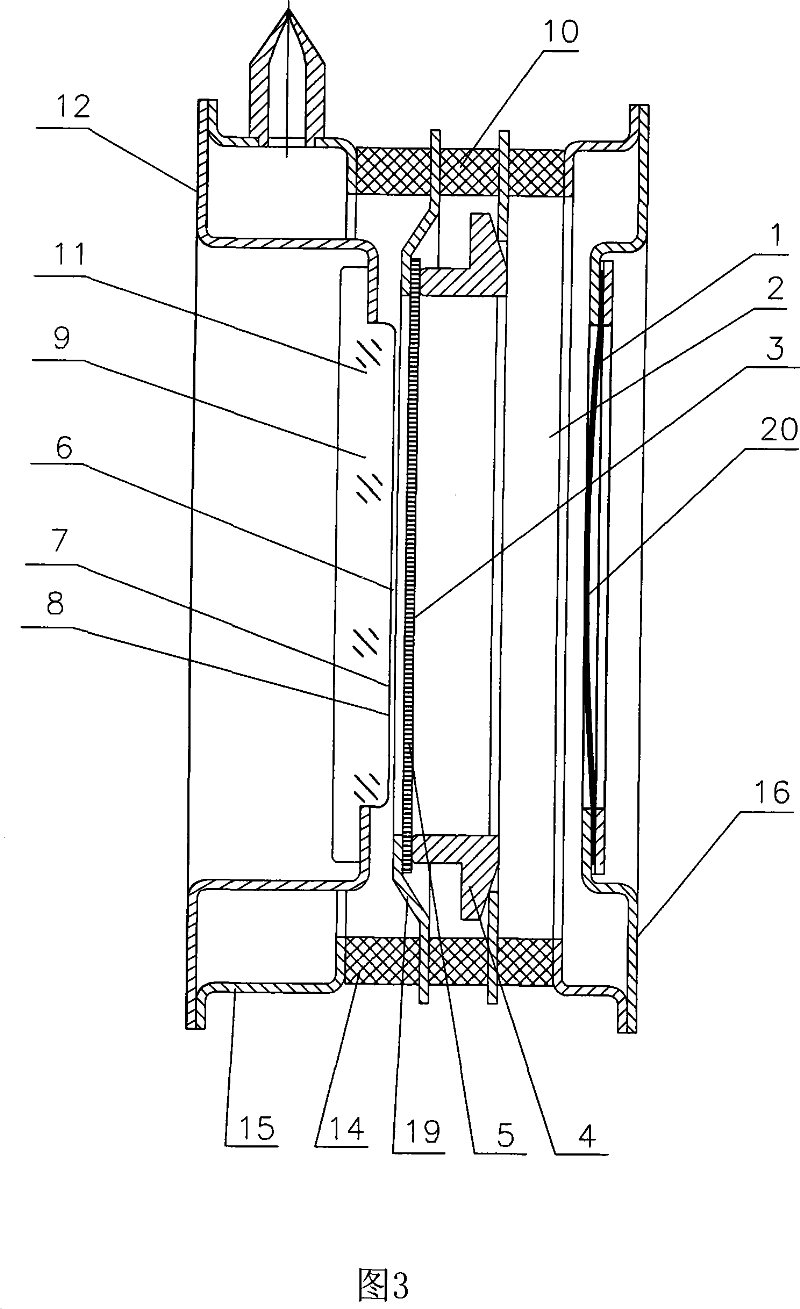

[0020] The structure of the present invention is shown in Fig. 1 and Fig. 3, comprises input window 1, reflective photocathode 3 sensitive to X-ray, microchannel plate assembly, output window 9 and housing 10, wherein input window 1, output window 9 and housing 10 constitute The vacuum seal 12, the casing 10 includes a sealing ring 16, a ceramic casing 14, and an output window metal casing 15 that are axially connected in sequence, and the input window 1 is a metal window 20 fixed in the middle of the front end of the sealing ring 16, and the metal window 20 adopts Pure aluminum / pure beryllium material, the thickness is 0.3-2mm, preferably 0.5-1mm, and the effective diameter is Φ18-Φ100mm, preferably Φ25-Φ100mm. The microchannel plate assembly comprises a pressure ring 4, a microchannel plate 5 and a tray 19 axially connected in sequence; the tray 19 is fixed in the middle of the ceramic shell 14, and the pressure ring 4 is fixed at the rear end of the sealing ring 16; the micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com