Sb doped P-type ZnO crystal film and preparation method thereof

A thin film and crystal technology, applied in the field of preparation of p-type ZnO crystal thin films, can solve the problems of low p-type conduction repeatability and stability, low solid solubility, deep acceptor energy level, etc. The effect of high concentration doping and low formation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1) Weigh ZnO and Sb with a purity of 99.99% 2 o 3 Powder, wherein the molar percentage of Sb is 2%. The weighed ZnO and Sb 2 o 3 The powder is poured into a ball mill jar equipped with agate balls, and milled on a ball mill for 12 hours, the purpose is to make the powder mix uniformly and refine to a certain extent. Then the raw materials are separated and dried, added with a binder for grinding, and pressed into shape. Put the molded green body into the sintering furnace, discharge elements at low temperature (400°C) to volatilize the binder, and then raise the temperature to 1200°C for sintering for 2 hours to obtain a Sb-doped ZnO ceramic target.

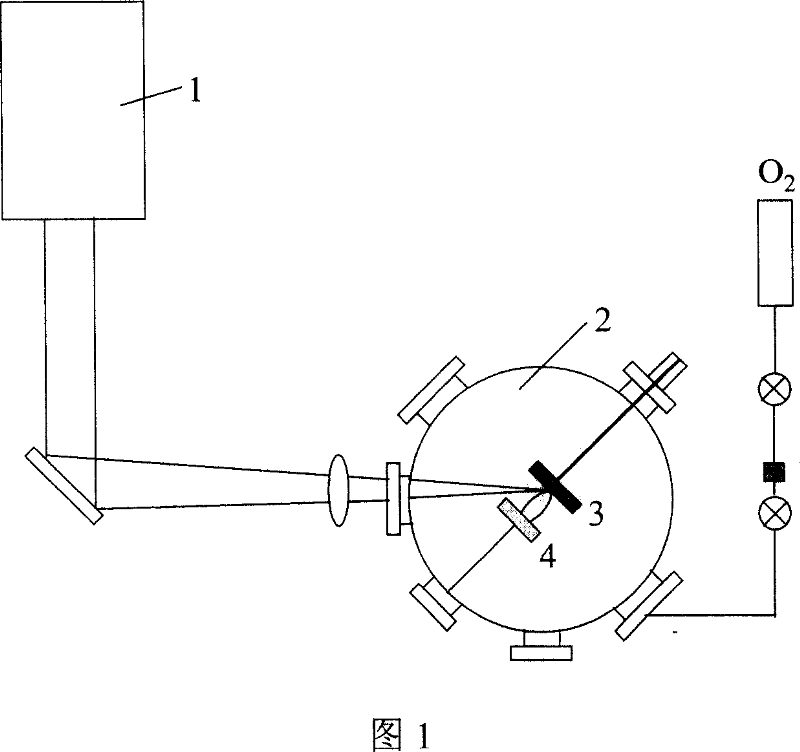

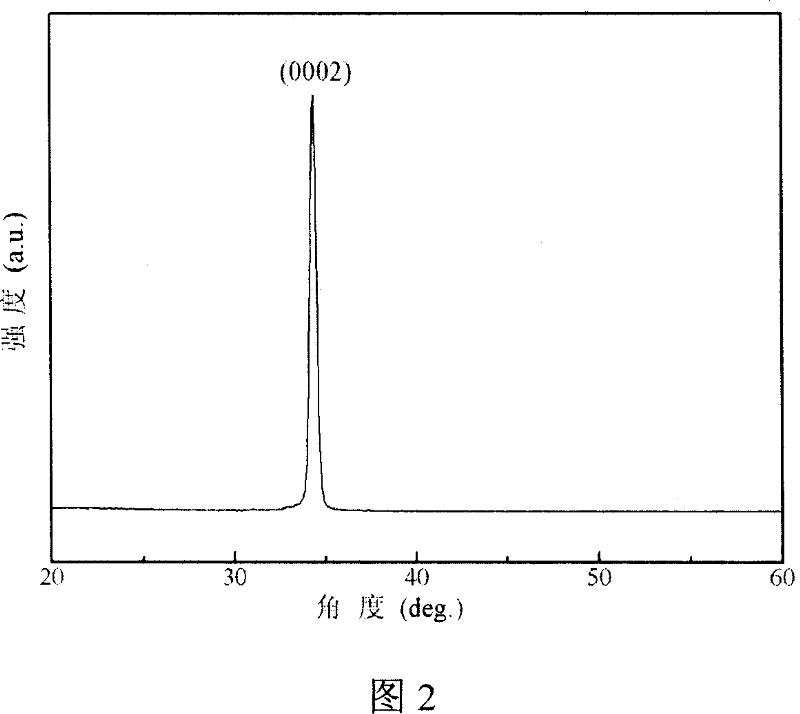

[0017] 2) Fix the quartz substrate on the sample stage after being cleaned, and put it into the growth chamber 2 . The Sb-doped ZnO ceramic target is installed on the target frame, and then embedded in the target holder of the pulsed laser deposition device. The distance between the substrate 4 and the target 3 was a...

Embodiment 2

[0021] 1) Weigh ZnO and Sb with a purity of 99.99% 2 o 3 Powder, wherein the molar percentage of Sb is 1.5%. The weighed ZnO and Sb 2 o 3 The powder is poured into a ball mill jar filled with agate balls, mixed evenly by ball milling, and pressed into shape. Put the molded green body into the sintering furnace, discharge elements at 400°C to volatilize the binder, then raise the temperature to 1000°C and sinter for 2 hours to obtain a Sb-doped ZnO ceramic target.

[0022] 2) Fix the silicon substrate on the sample stage after cleaning, and put it into the growth chamber. The Sb-doped ZnO ceramic target was placed in the target holder of the pulsed laser deposition device. Adjust the distance between the substrate and the target to 5.5 cm, and place the baffle between the substrate and the target. Vacuum the growth chamber to 4×10 -4 Pa, the substrate is heated to 600°C. Pure O 2 , the pressure is controlled at 0.1Pa. Turn on the laser (pulse laser energy 300mJ, frequ...

Embodiment 3

[0025] 1) Weigh ZnO and Sb with a purity of 99.99% 2 o 3 Powder, wherein the molar percentage of Sb is 4%. The weighed ZnO and Sb 2 o 3 The powder is poured into a ball mill jar, the ball mill is mixed evenly, and pressed into shape. Put the molded green body into the sintering furnace, discharge elements at 400°C to volatilize the binder, then raise the temperature to 1100°C and sinter for 2 hours to obtain a Sb-doped ZnO ceramic target.

[0026] 2) Fix the glass substrate on the sample stage after cleaning, and put it into the growth chamber. The Sb-doped ZnO ceramic target was placed in the target holder of the pulsed laser deposition device. Adjust the distance between the substrate and the target to be 4.5 cm, and place the baffle between the substrate and the target. Vacuum the growth chamber to 4×10 -4 Pa, the substrate is heated to 400°C. Pure O 2 , the pressure is controlled at 0.7Pa. Turn on the laser (pulse laser energy is 300mJ, frequency 3Hz), pre-deposi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Hole concentration | aaaaa | aaaaa |

| Hall mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com