A CVD-based strained diamond growth doping method

A diamond and diamond layer technology, applied in metal material coating process, coating, gaseous chemical plating and other directions, can solve the problems of difficult doping, high formation energy, limiting the electrical properties of n-type diamond, and reduce the resistivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

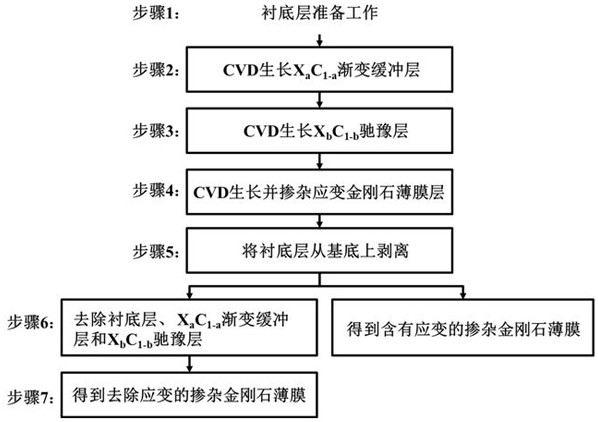

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

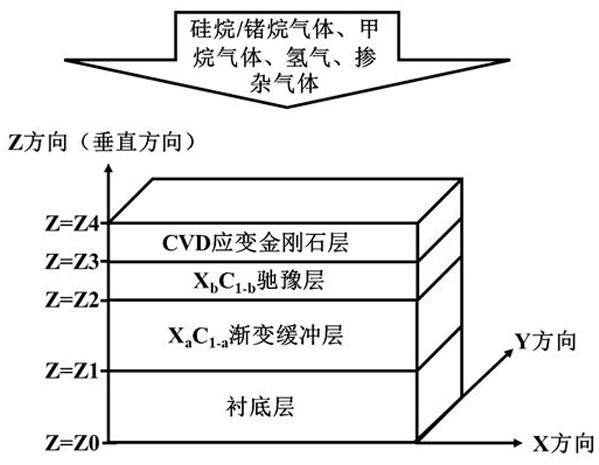

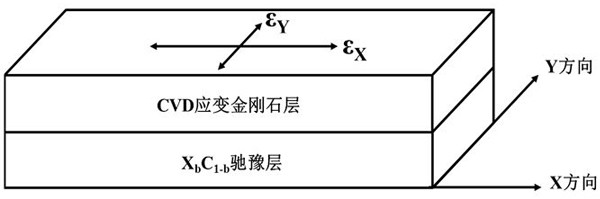

[0022] Such as figure 1 As shown, the present invention provides a strained diamond growth doped epitaxial structure based on the CVD method, through the CVD method, from bottom to top in the vertical direction, sequentially deposit X on the substrate layer a C 1-a Gradient Buffer, X b C 1-b relaxation layer, eventually at X b C 1-b A layer of CVD strained diamond is deposited on top of the relaxed layer.

[0023] Such as figure 1 As shown, the vertical thickness of the substrate layer material is between Z=Z0 and Z=Z1.

[0024] Such as figure 1 Shown, X a C 1-a The vertical thickness of the gradient buffer layer is between Z=Z1 and Z=Z2.

[0025] Such as figure 1 Shown, X b C 1-b The vertical thickness of the relaxed layer is between Z=Z2 and Z=Z3.

[0026] Such as figure 1 As shown, the vertical thickness of the CVD strain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com