Preparation method of echo wall die laser cavity based on zinc oxide single crystal micronano dish

A zinc oxide single crystal, whispering gallery mode technology, applied in the field of zinc oxide micro/nano laser cavity, can solve the problems of high WGM laser threshold, low quality factor Q value, complex preparation process, etc., to reduce scattering loss and substrate Loss caused by absorption, the effect of simple method and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

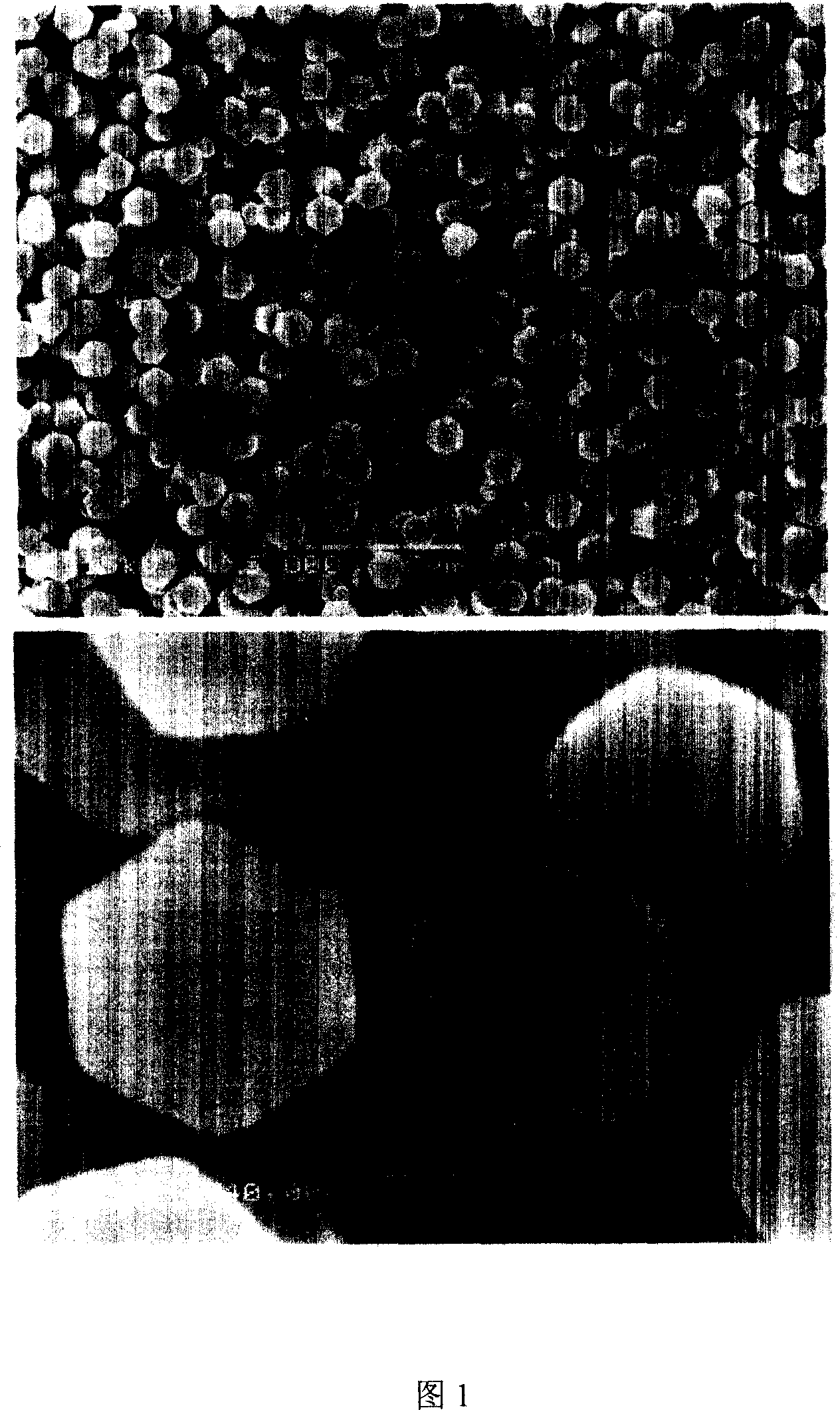

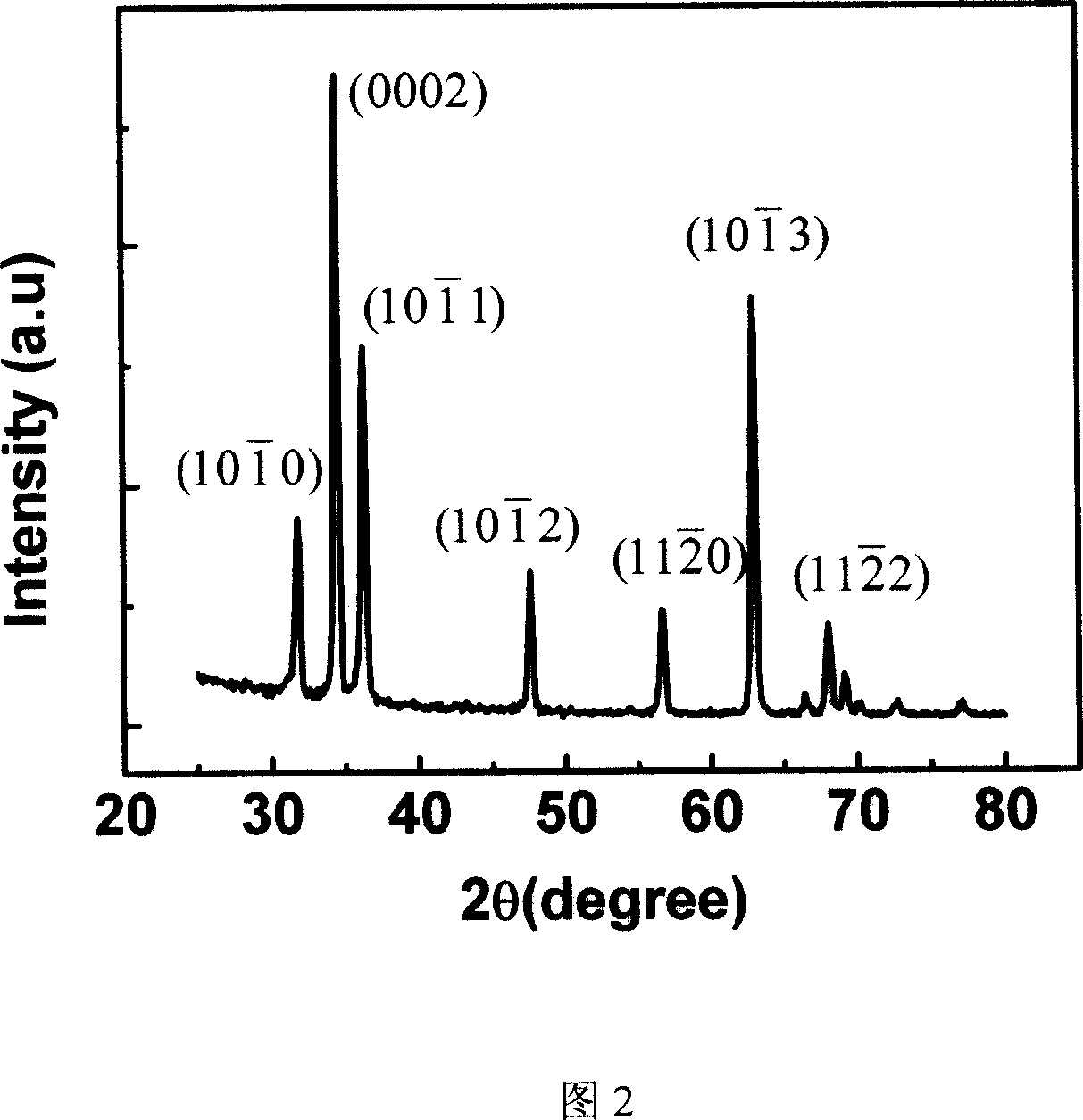

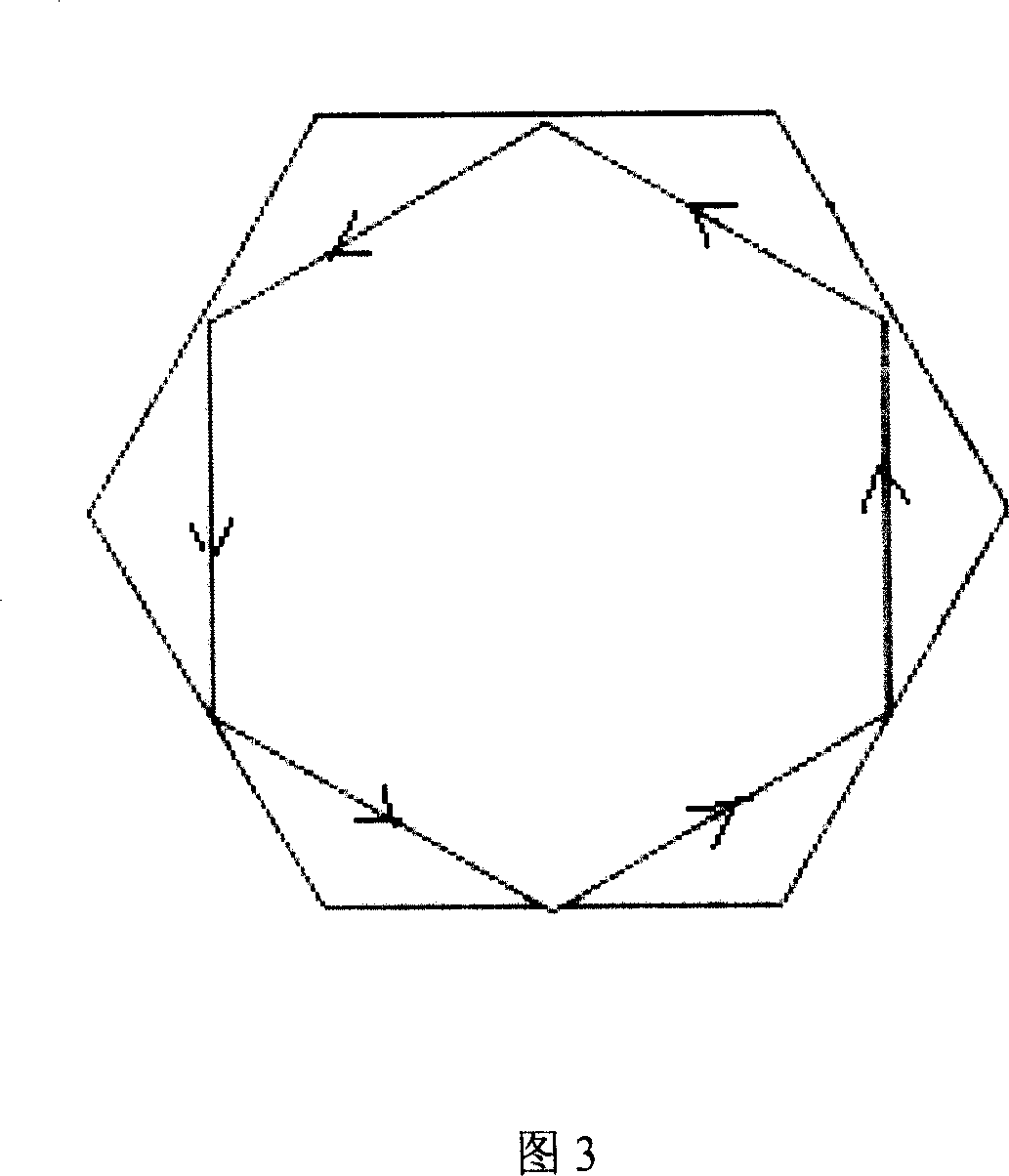

[0016] A method for preparing a whispering gallery mode laser cavity based on zinc oxide single crystal micro-nano discs, using zinc powder with a mass content greater than or equal to 99.99% as a reaction raw material, and oxygen with a mass concentration greater than or equal to 99.99% as a reaction gas. Silicon wafer or sapphire wafer is used as the substrate, and nitrogen is used as the transport gas to keep the zinc powder at a temperature of 700-800°C. The zinc powder is evaporated into zinc vapor, and the zinc vapor is transported to the substrate area by nitrogen. At a temperature of 400-500 It is deposited on the substrate at ℃ and oxidized into zinc oxide nuclei, and finally grows from these nuclei into a micro / nano-sized hexagonal symmetrical disc structure, and the above reaction will be completed within 30-60 minutes. In this embodiment, the mass content of zinc powder is 99.99% or 99.999%, the mass concentration of oxygen is 99.99% or 99.999%, the heating evaporat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com