Curable organometallic composition, organometallic polymer material and optical component

A polymer material and organometallic technology, applied in the field of organometallic polymer materials, can solve the problems of high refractive index, low curing shrinkage, and inaccessibility, and achieve the effects of excellent heat resistance, separation suppression, and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

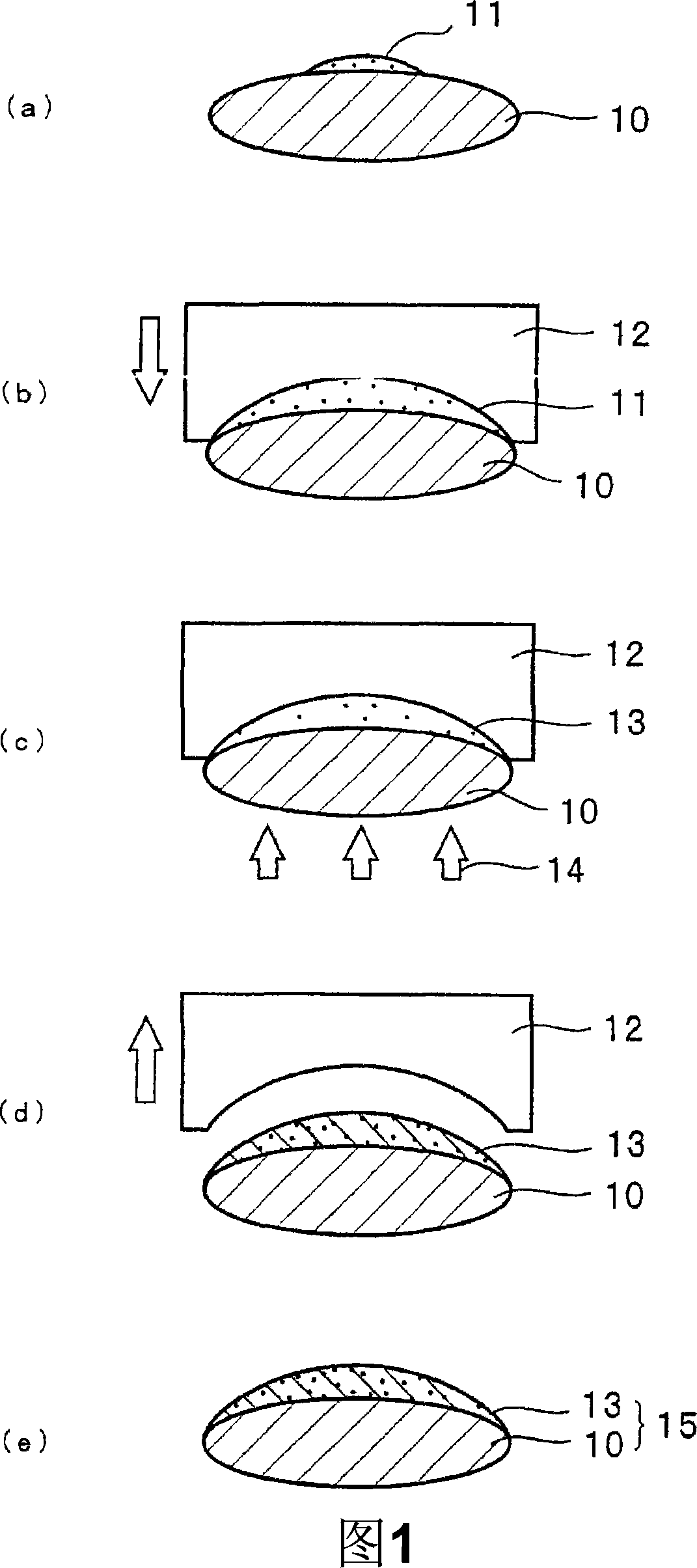

Method used

Image

Examples

Embodiment 1

[0088] As the fluorene-based compound, fluorene acrylate having the structure represented by the above chemical formula 1 and having m and n being 1 was used.

[0089]

[0090] Viscous liquid A was obtained by mixing the following with heating at 60°C:

[0091] Fluorenyl acrylate: 10g;

[0092] 1-Hydroxy-cyclohexyl-benzophenone: 0.2g;

[0093] HALS (Tinuvin292 produced by Ciba Specialty Chemicals): 0.05g;

[0094] UV absorber (Tinuvin400 produced by Ciba Specialty Chemicals): 0.15g; and

[0095] Benzyl methacrylate: 1.43 g.

[0096]

[0097] Organometallic Compound A and Organometallic Compound B were hydrolyzed and polycondensed by mixing and standing for 24 hours:

[0098] Organometallic compound A: 3-methacryloxypropyltriethoxysilane: 15.3ml;

[0099] Organometallic compound B: diphenyldimethoxysilane: 6.3ml;

[0100] An aqueous solution containing hydrochloric acid as a reaction catalyst (hydrochloric acid at a concentration of 2N: 3.8 ml); and

[0101] Ethanol:...

Embodiment 2

[0129] In Example 1, except that the addition amount of the organometallic polymer was set to 29% by weight, and benzyl methacrylate was not contained in the viscous liquid A, a curable organometallic composition was prepared in the same manner as in Example 1, The volume cure shrinkage, the refractive index, the Abbe number, and the temperature coefficient of the refractive index of the cured product after curing were measured.

[0130] The volume curing shrinkage is about 5.1%, the refractive index is about 1.60, the Abbe number is about 28, and the temperature coefficient of the refractive index is about -1.6×10 -4 .

Embodiment 3

[0137] In Example 1, viscous liquid B was prepared by using 3-mercaptopropyltrimethoxysilane as organometallic compound A used for viscous liquid B. The content of organometallic compound A is 9.8ml, the content of organometallic compound B is 6.3ml, the concentration of 2N hydrochloric acid is 3.8ml, and the amount of ethanol is 40ml. By mixing the above substances and standing for 24 hours, the organometallic compound A and the organometallic compound B were hydrolyzed and polycondensed.

[0138] The obtained liquid containing the polycondensate is heated to 100°C under a nitrogen atmosphere, ethanol and methanol produced by the reaction are evaporated, and the obtained liquid is used as viscous liquid B and mixed with viscous liquid A to allow the addition of the organometallic polymer. The amount was 29% by weight, and an organometallic composition was prepared.

[0139] The obtained curable organometallic polymer was cured in the same manner as described above, and the v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com