Soft magnetic structural steel plate with excellent welding performance and its making process

A technology of welding process and structural steel plate, which is applied to soft magnetic structural steel plate with excellent welding processability and its manufacturing field, and can solve the problems of reducing the magnetic flux density of the steel plate, affecting the steel plate manufacturing cycle and delivery schedule, and affecting the construction progress of the project, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

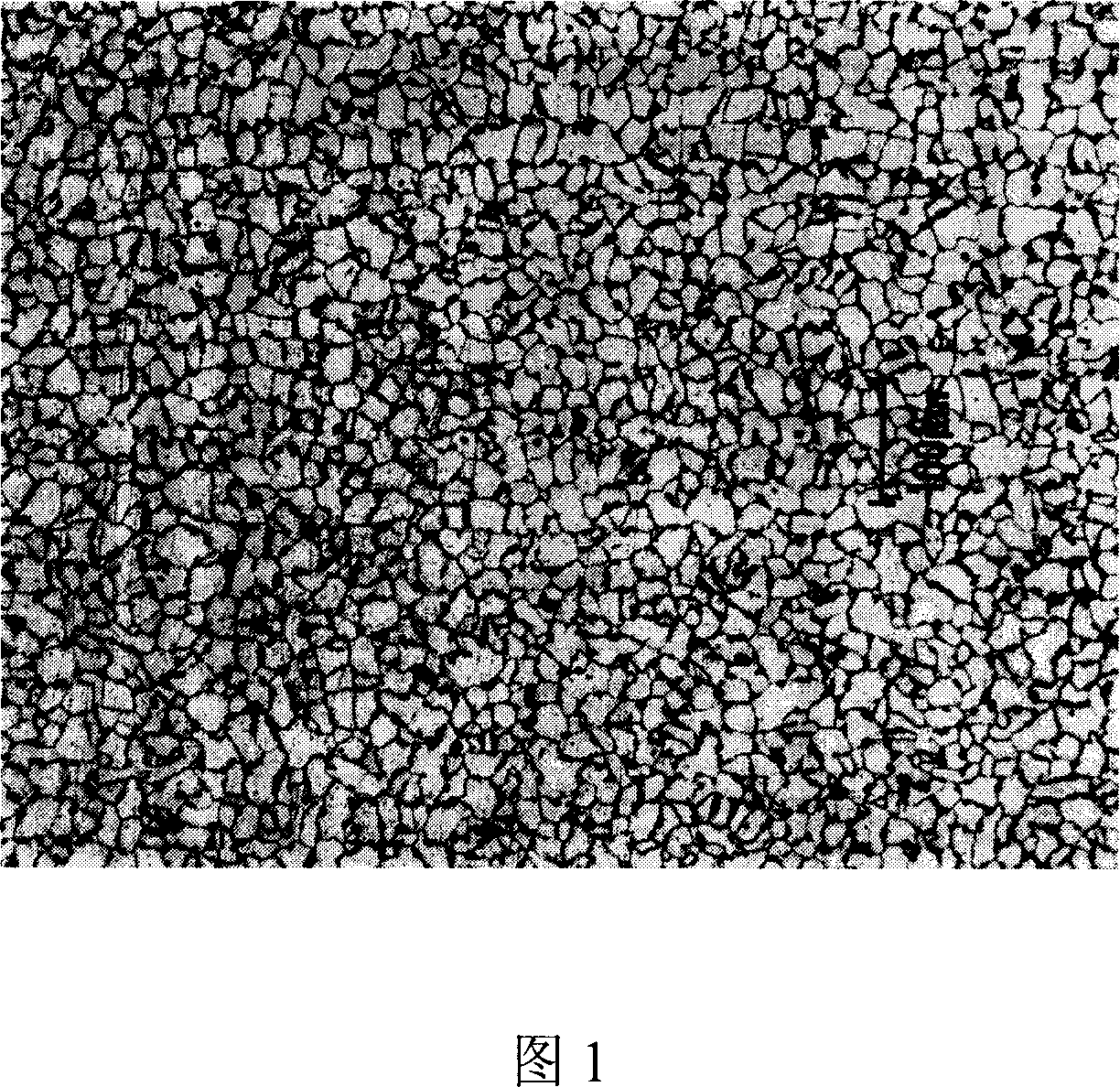

Image

Examples

Embodiment

[0078] Embodiment: The manufacturing process of the soft magnetic structural steel plate of the present invention is as follows: smelting in a vacuum induction furnace in a laboratory, and casting starts immediately after the composition of the molten steel reaches the target composition, and the casting temperature of the molten steel is 1525°C to 1550°C. The soaking time of the slab in the heating furnace = plate thickness (mm) × (0.5 ~ 1.0) min / mm, the soaking temperature is 1050°C ~ 1100°C, the hot rolling adopts 9-pass rolling process, and the pass reduction rate Between 13% and 18%, the cumulative reduction rate is 70% to 90%, the final rolling temperature is 800°C to 850°C, the transfer time between the end of final rolling and the start of accelerated cooling is 15s to 30s, and the accelerated cooling is started When the surface temperature of the steel ingot is above 800°C, the accelerated cooling rate is 10°C / s-20°C / s, the cooling stop temperature is 500°C-550°C, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com