Multilayer nanometer porous SnO2 film and its synthesis process

A technology of tin dioxide and nano-film, applied in the direction of material resistance, etc., can solve problems such as unsatisfactory performance, and achieve the effects of low power consumption, good chemical stability, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

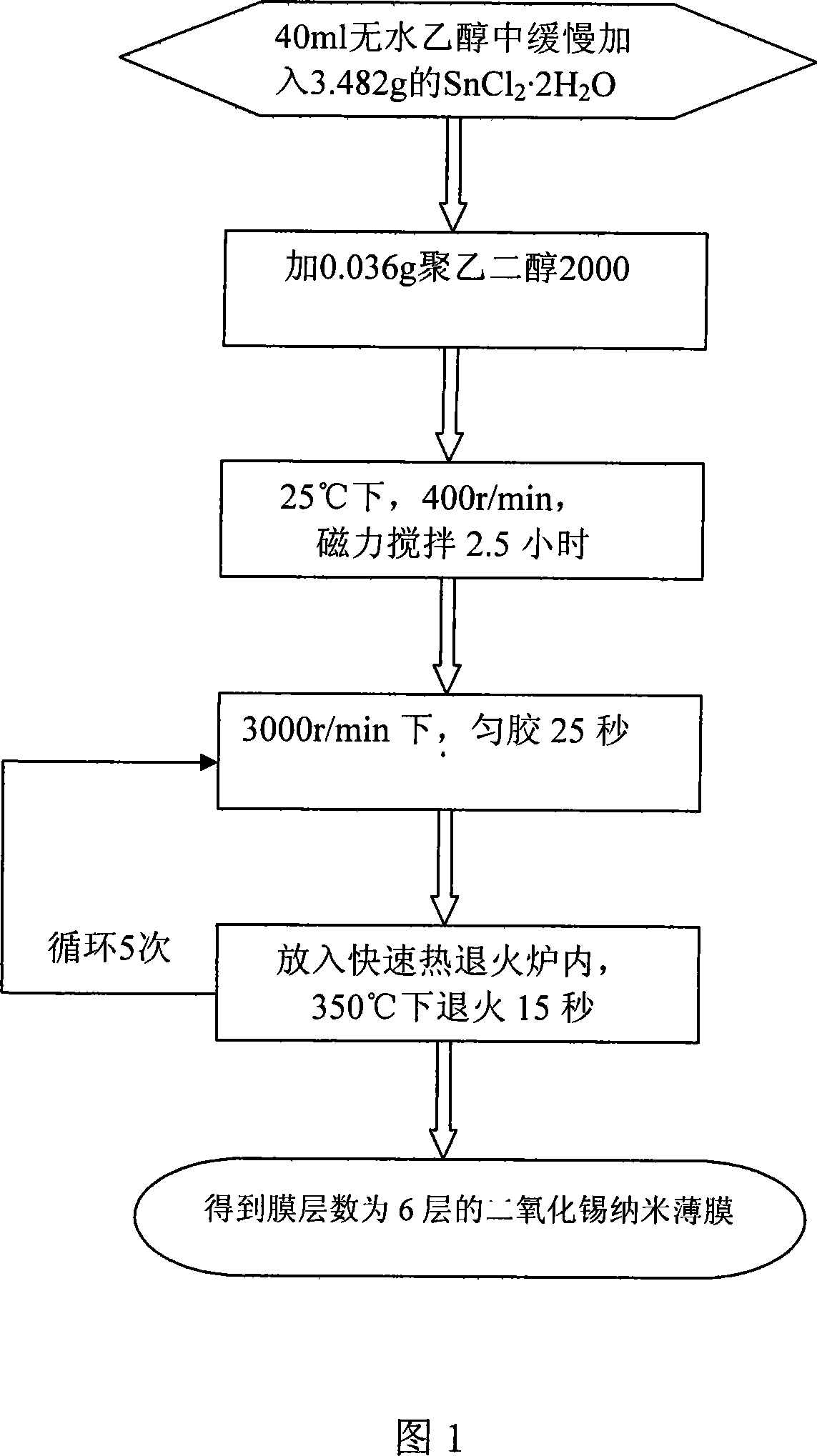

Embodiment 1

[0033] In the first step, the metal inorganic salt SnCl 2 2H 2The consumption of O and dehydrated alcohol is respectively 40ml and 3.462g, and the concentration of the precursor solution that is used to make tin dioxide nanofilm is 0.38mol / L; In the second step, tensio-active agent is polyethylene glycol 2000 , the addition amount is 0.036g, the weight ratio of surfactant to precursor solution is 0.1%; in the third step, at 25°C, magnetic stirring is carried out for 2.5 hours, the stirring speed is 400 rpm, and the aging time is 24 hours. The magnetic stirrer used It is a digital display constant temperature magnetic stirrer with a model of HOI-1B; in the fourth step, the single crystal silicon substrate is a silicon wafer with a resistivity, thickness and crystal orientation of 8Ω·cm, 380±10μm and (111) respectively, at 2500 Under the rotating speed of rev / min, glue evenly 25 seconds, glue film thickness is 150 nanometers, used glue even machine is the desktop glue even mach...

Embodiment 2

[0035] In the first step, the metal inorganic salt SnCl 2 2H 2 The consumption of O and dehydrated alcohol is respectively 40ml and 3.644g, and the concentration of the precursor solution that is used to make tin dioxide nano film is 0.4mol / L; In the second step, tensio-active agent is polyethylene glycol 2000 , the addition amount is 0.4g, and the weight ratio of surfactant to precursor solution is 1.1%; in the third step, at 80°C, stir magnetically for 3 hours at a stirring speed of 500 rpm, and age for 42 hours. The magnetic stirrer used It is a digital display constant temperature magnetic stirrer with a model of HOI-1B; in the fourth step, the single crystal silicon substrate is a silicon wafer with a resistivity, thickness and crystal orientation of 8Ω·cm, 380±10μm and (111) respectively, at 3000 Under the rotating speed of rev / min, glue uniformly 35 seconds, film thickness is 200 nanometers, used glue homogenizer is the desktop glue homogenizer of KW-4A type; The mono...

Embodiment 3

[0037] In the first step, the metal inorganic salt SnCl 2 2H 2 The consumption of O and dehydrated alcohol is respectively 40ml and 4.1g, and the concentration of the precursor solution that is used to make tin dioxide nanofilm is 0.45mol / L; In the second step, tensio-active agent is polyethylene glycol 2000 , the addition amount is 1.2g, and the weight ratio of surfactant to precursor solution is 3.18%; in the third step, at 95°C, stir magnetically for 3.5 hours at a stirring speed of 600 rpm, and age for 60 hours. The magnetic stirrer used It is a digital display constant temperature magnetic stirrer with a model of HOI-1B; in the fourth step, the single crystal silicon substrate is a silicon wafer with a resistivity, thickness and crystal orientation of 8Ω·em, 380±10μm and (111) respectively, at 3000 Under the rotating speed of rev / min, glue evenly 50 seconds, glue film thickness is 250 nanometers, used glue even machine is the desktop type glue even machine of KW-4A; The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| crystal orientation | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com