Magnetic storage device

A magnetic storage and magnetic head technology, applied in information storage, recording information storage, magnetic recording, etc., can solve the problems of increased coercivity, difficulty in recording, and increased magnetic anisotropy of magnetic particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

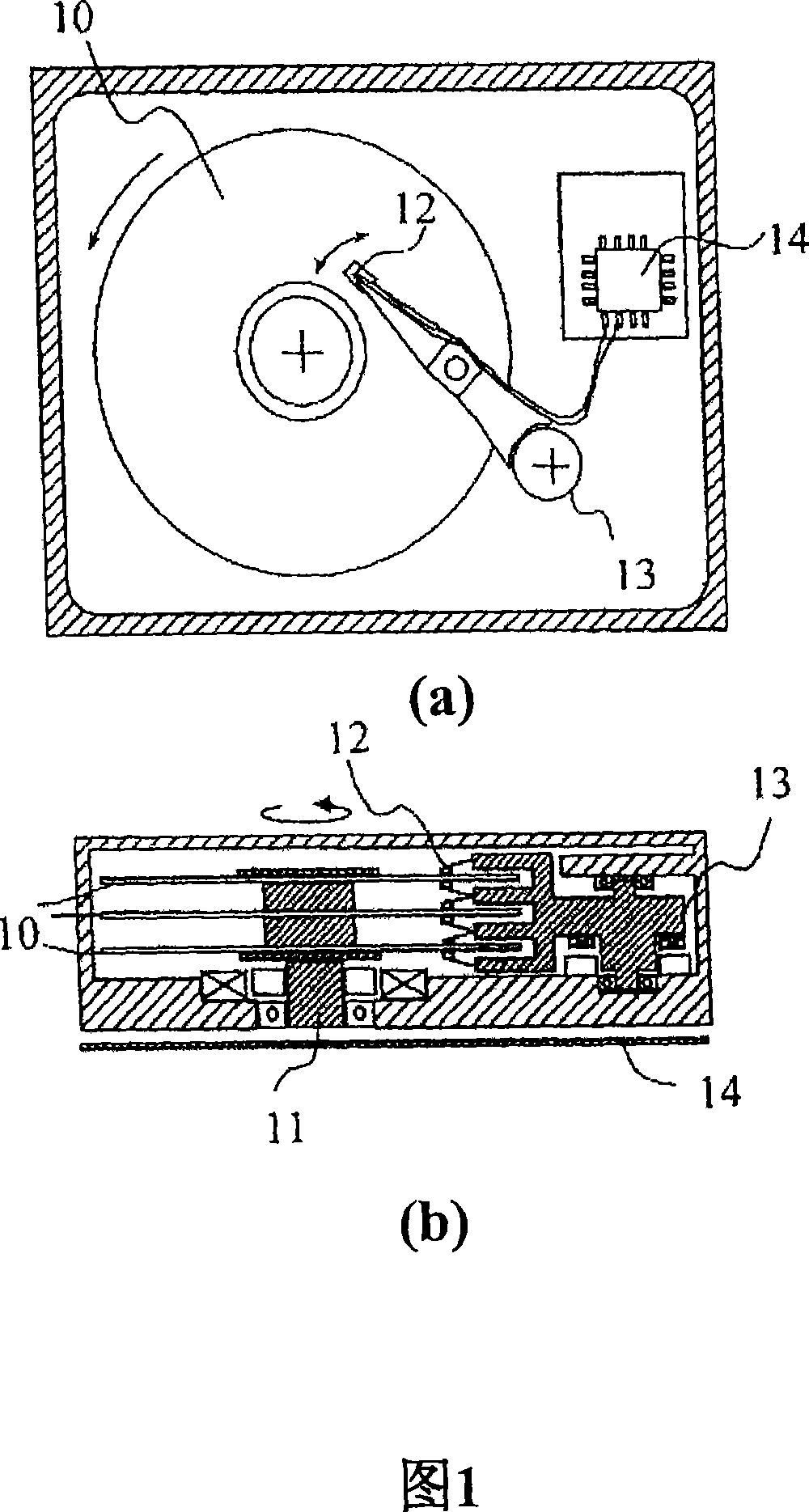

[0080] FIG. 1 is a schematic diagram showing one embodiment of a magnetic memory device according to the present invention.

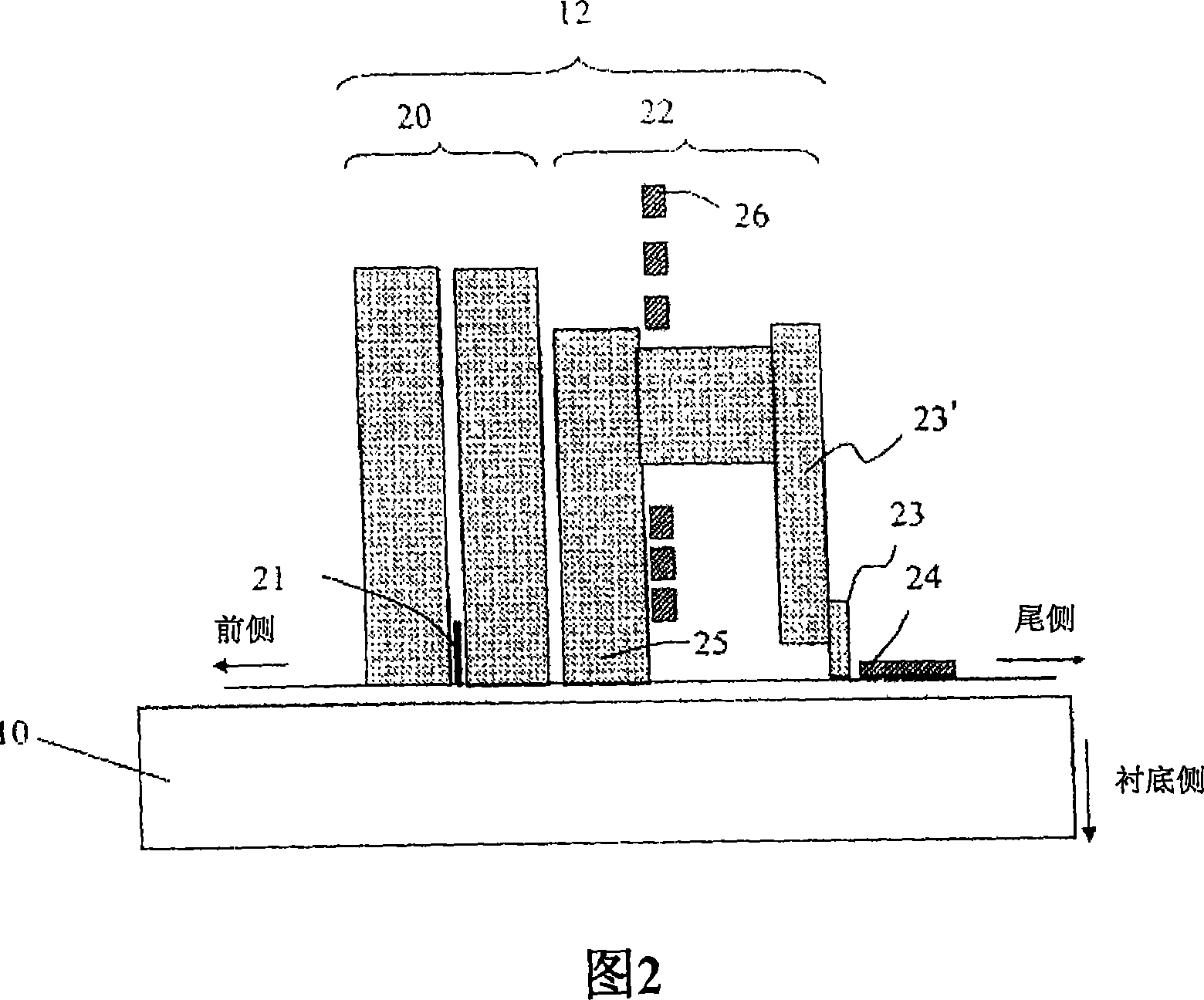

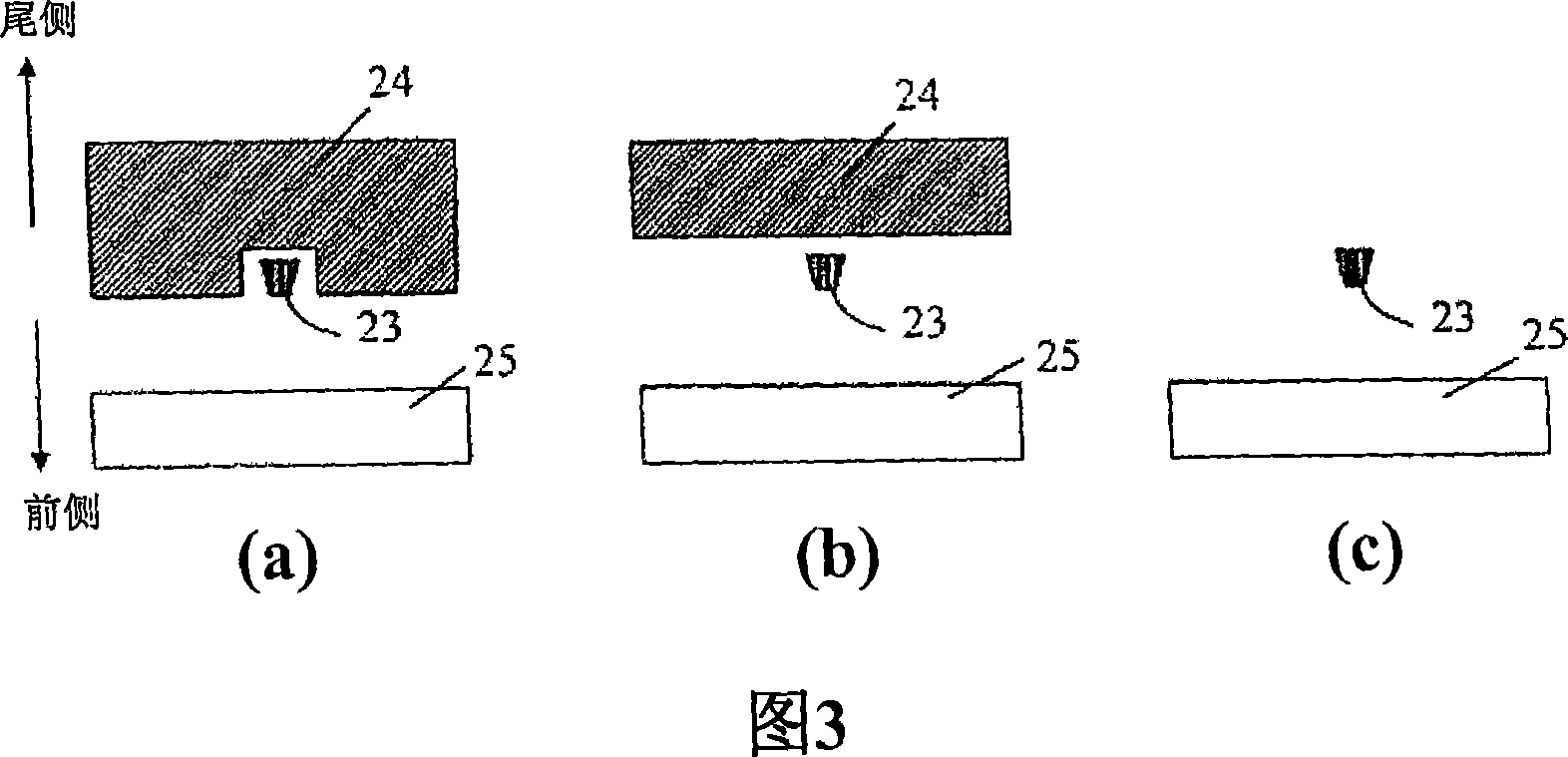

[0081] The magnetic storage device has a perpendicular magnetic recording medium 10, an actuator 11 for driving the perpendicular magnetic recording medium, a magnetic head 12 including a writer and a reader, a device 13 for moving the magnetic head relative to the magnetic recording medium, and a device for processing the given magnetic recording medium. Means 14 for input signals to the head and output signals from the head. FIG. 2 shows the relationship between the magnetic head 12 and the perpendicular magnetic recording medium 10 . The magnetic flying height of the magnetic head is 8nm. The reader 20 has a read element 21 sandwiched by a pair of magnetic shields, for which a giant magnetoresistive element (GMR) is used. In addition to the giant magnetoresistance element, the read element 21 may be a tunneling magnetoresistance element (TMR) or a ...

Embodiment 2

[0140] The magnetic storage device of this embodiment has the same structure as that of Embodiment 1 except for the perpendicular magnetic recording medium 10 . The perpendicular magnetic recording medium 10 was manufactured using the same sputtering system, layer structure, and process conditions as in Embodiment 1 described above. For the adhesive layer 42, Al-50 at.% Ti with a film thickness of 5 nm was used instead of the NiTa alloy. For the soft magnetic lower layer 43, 51at.%Fe-34at.%Co-10at.%Ta-5at.%Zr was used instead of the CoTaZr alloy. The film thickness of Ru in the AFC structure is 0.45 nm. In the fabrication medium, a value of 5 nm, 10 nm, 15 nm, 20 nm, 25 nm, 30 nm, 40 nm, or 50 nm was used for the film thickness of the FeCoTaZr alloy of each layer. A sample with a soft magnetic lower layer and no upper layer was also produced, and when a maximum magnetic field of 1035 kA / m was applied to the in-plane direction of the film using a vibrating sample magnetometer...

Embodiment 3

[0179] The magnetic storage device of this embodiment has the same structure as that of Embodiment 1 except for the perpendicular magnetic recording medium 10 . The perpendicular magnetic recording medium 10 was manufactured using the same sputtering system, layer structure, and process conditions as those in the aforementioned embodiment 1. For the adhesive layer 42, Al-50 at.% Ti of 5 nm film thickness was used instead of the NiTa alloy. For the soft magnetic lower layer 43, Fe-30at.%Co-15at.%B was used instead of the CoTaZr alloy. The film thickness of Ru in the AFC structure is 0.6 nm. In the fabrication medium, a value of 5 nm, 10 nm, 15 nm, 20 nm, 25 nm, 30 nm, 40 nm, or 50 nm is used for the film thickness of the FeCoB alloy of each layer. A sample with a soft magnetic lower layer and no upper layer was also fabricated, and when a maximum magnetic field of 1035 kA / m was applied to the in-plane direction of the film using a vibrating sample magnetometer, the estimated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| saturation flux density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com